Anti-overheating equipment for assembly welding

An assembly welding and anti-overheating technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slow heat dissipation and difficulty in fixing the water suction port, and achieve strong applicability, avoid excessive temperature, Guaranteed temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

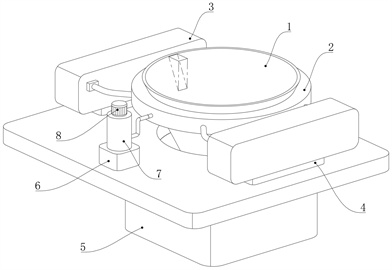

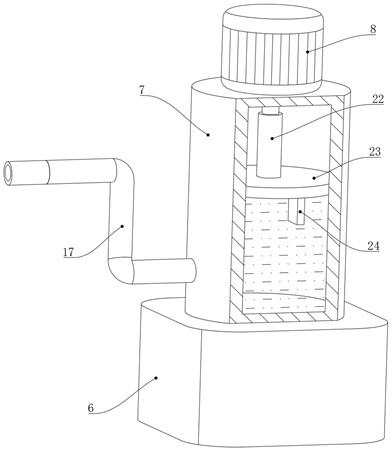

[0021] refer to figure 1 , an anti-overheating device for assembly and welding, including a workbench 5, a bucket groove is opened on the upper surface of the workbench 5, a fixing ring 2 is fixedly installed on the workbench 5 through a bracket, and the fixing ring 2 is located directly above the bucket groove, and fixed The inner diameter of the ring 2 is larger than the diameter of the bucket groove. An annular groove is coaxially opened on the inner ring wall of the fixed ring 2. A heat conduction mechanism is arranged in the annular groove. 5 is also provided with a refrigeration mechanism that cooperates with the heat conduction mechanism.

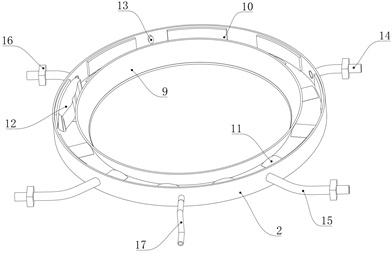

[0022] refer to image 3 , the heat conduction mechanism includes an expansion ring 9 that is sealed and fixedly connected at the notch of the annular groove, the sealed space formed by the annular groove and the expansion ring 9 is a heat conduction area, and the expansion ring 9 is glued and fixed by an anti-skid layer 901, a rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com