Substrate pick-and-place device and pick-and-place method

A substrate and vacuum suction cup technology, which is applied to program control manipulators, manufacturing tools, chucks, etc., can solve the problems of abnormal vacuum suction, low production efficiency, machine downtime, etc. The effect of vacuum anomalies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. In the drawings, for clarity and ease of understanding and description, the dimensions and thicknesses of components depicted in the drawings are not to scale.

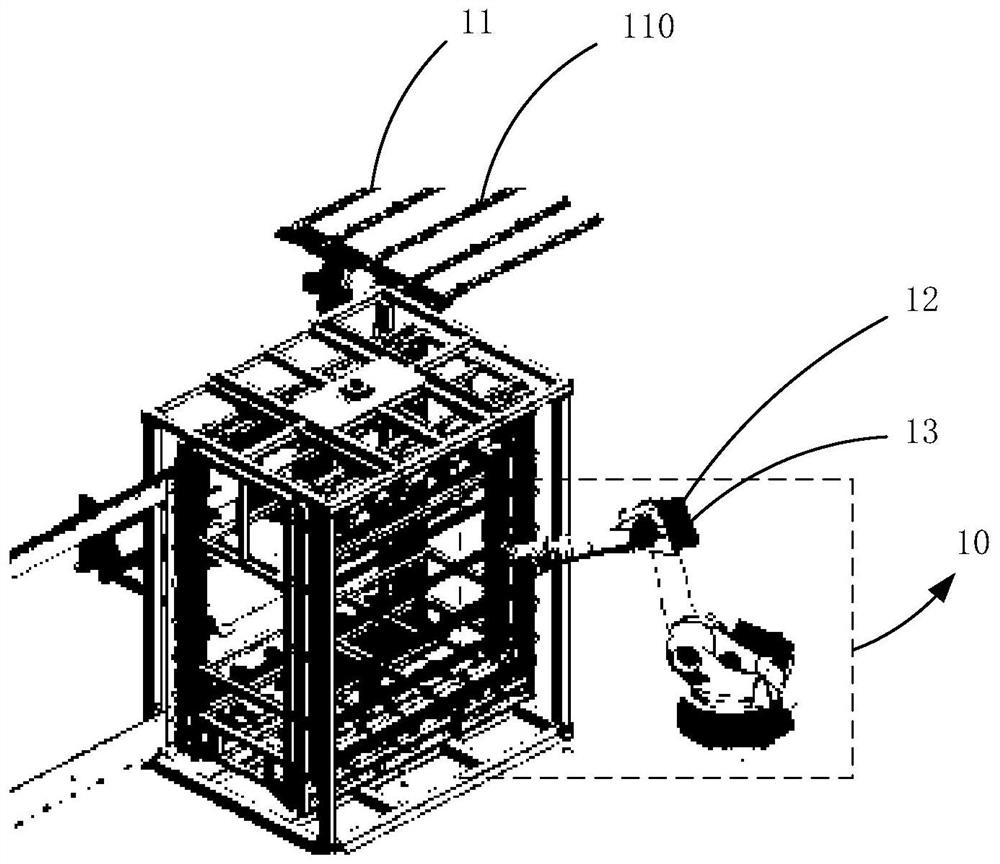

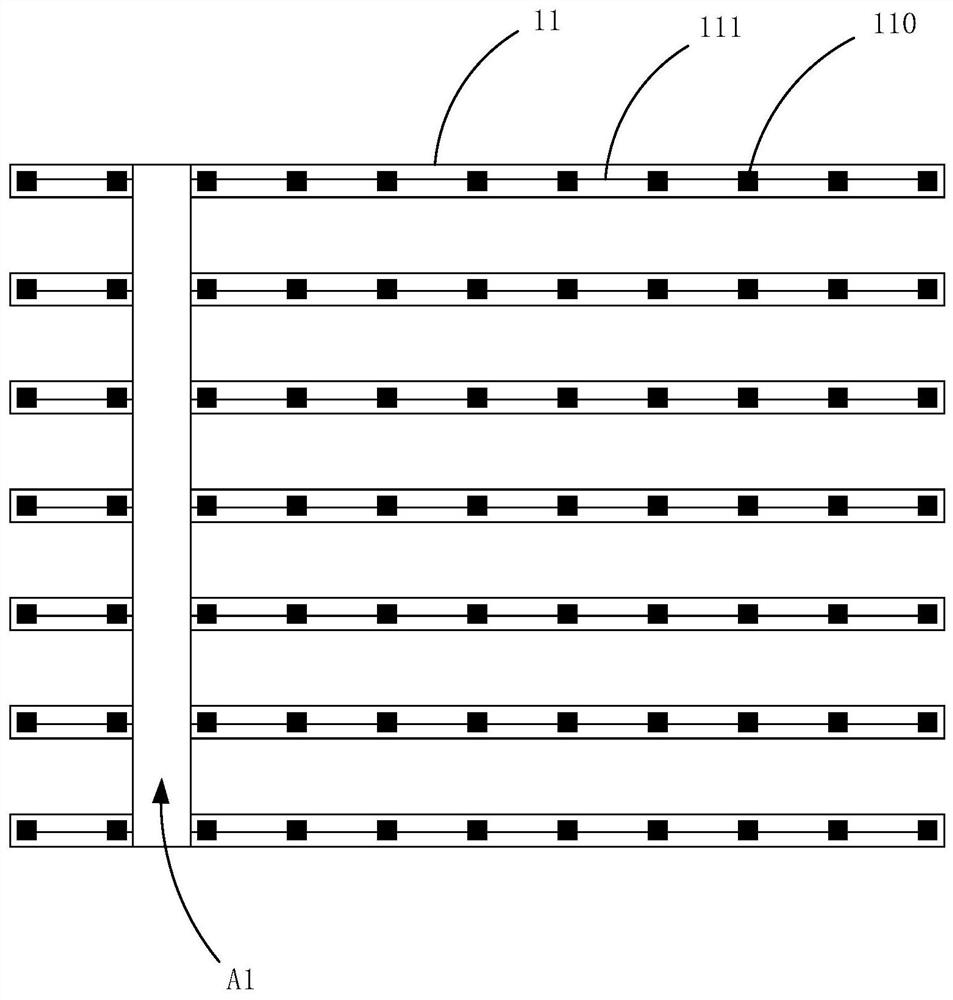

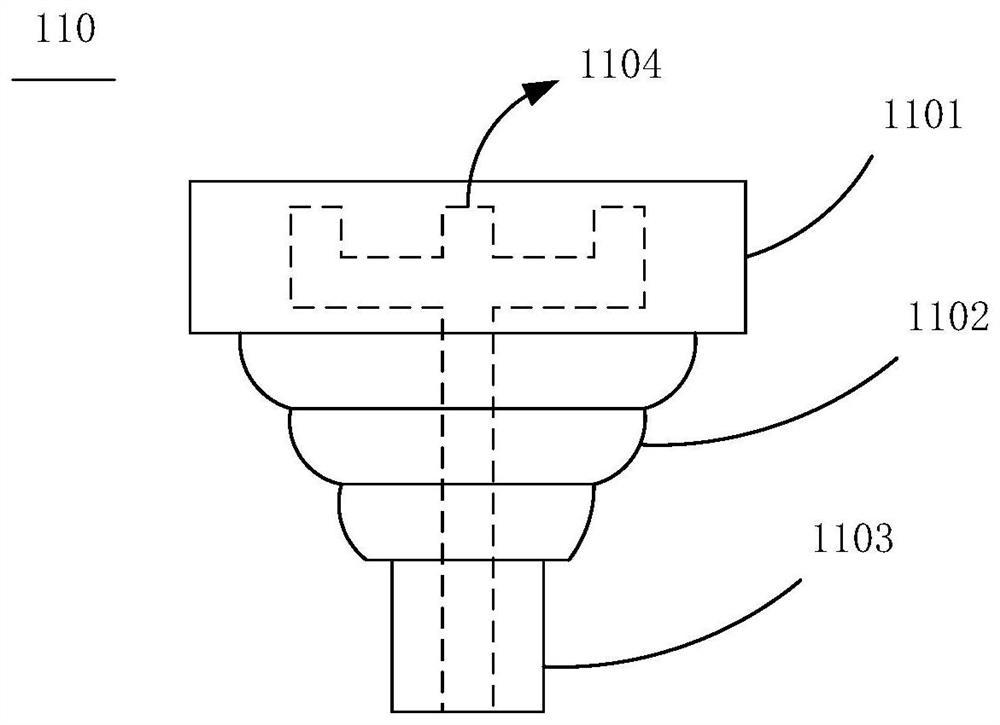

[0028] like figure 1 , figure 2 As shown, it is a schematic diagram of the basic structure of a substrate pick-and-place device provided by an embodiment of the present invention and a schematic diagram of a basic structure of a substrate fork provided by an embodiment of the present invention. The substrate pick-and-place device includes at least one robotic arm 10. A plurality of substrate forks 11 are provided thereon, and each of the substrate forks 11 is provided with a plurality of vacuum suction cups 110 and a CDA (Compressed Dry Air, compressed dry air) pipeline 111 connected to the plurality of vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com