Safety protection device of lifting belt or traction belt and use method of safety protection device

A technology of safety protection device and traction belt, applied in the direction of safety device, belt fasteners, transportation and packaging, etc., can solve problems such as damage, cuts, casualties, equipment, etc., and achieve the effect of avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

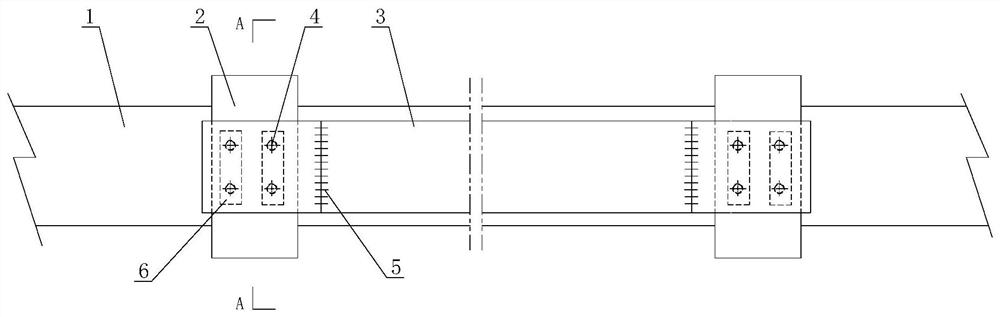

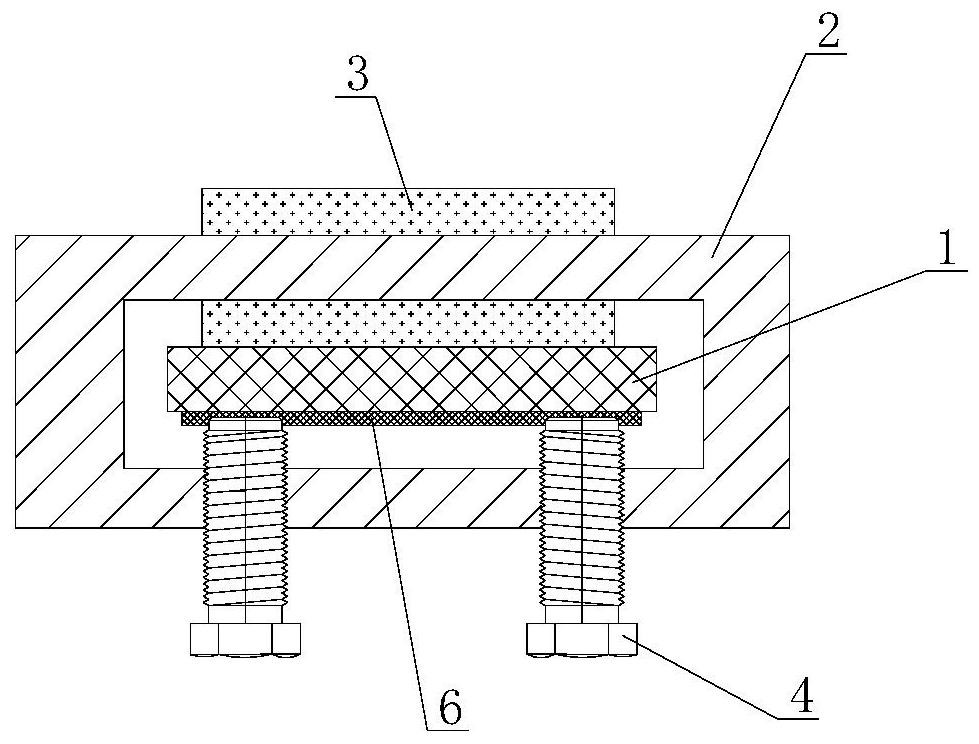

[0031] Such as figure 1 , figure 2 As shown, in this embodiment, the safety protection device is located in the middle of the sling / traction belt 1, and consists of 2 lead weights 2, 1 high-strength elastic band 3, 8 bolts 4, and 4 rubber backing plates 6.

[0032] The two ends of the high-strength elastic band 3 are fixedly connected to the lead block 2 as follows: the lead block 2 is a fully enclosed ring structure, and the two ends of the high-strength elastic band 3 pass through the middle hole of the corresponding lead block 2 and bypass the corresponding lead block. The top of the block 2 is sewn up with the high-strength elastic band 3 at the inner end of the lead block 2 (sewing place 5 such as figure 1 shown); four threaded holes are provided at the bottom of each lead block 2, and the sling / traction belt 1 is tightened on the inner side of the lead block 2 through four bolts 4 passing through the corresponding threaded holes (with a layer between the two High-stre...

Embodiment 2

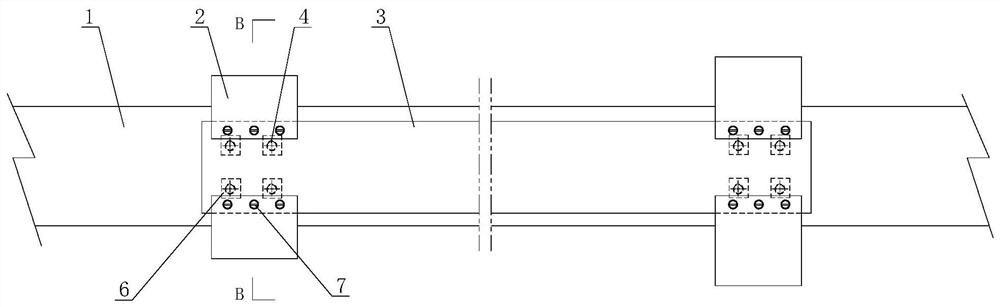

[0036] Such as image 3 , Figure 4 As shown, in this embodiment, the safety protection device is located in the middle of the sling / traction belt 1, consisting of 2 lead weights 2, 1 high-strength elastic belt 3, 8 bolts 4, 8 rubber pads 6 and 12 Fastening screw 7 forms.

[0037] The two ends of the high-strength elastic band 3 are fixedly connected to the lead block 2 as follows: the lead block 2 is a semi-closed ring structure, and a gap is opened in the middle of the top; positioning notches are provided on the top surface of the lead block 2 on both sides of the gap, and the high-strength elastic band The two ends of 3 are placed in corresponding positioning notches, and the high-strength elastic band 3 at both ends and the corresponding lead block 2 are respectively locked and fixed by 6 fastening screws 7; the bottom of each lead block 2 is provided with 4 threaded holes, After the four bolts 4 pass through the corresponding threaded holes, the sling / traction belt 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com