Building fire-fighting robot

A fire-fighting robot, robot technology, applied in fire rescue and other directions, can solve problems such as personal injury, and achieve the effect of avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The following is attached Figure 1-6 The present invention is described in further detail.

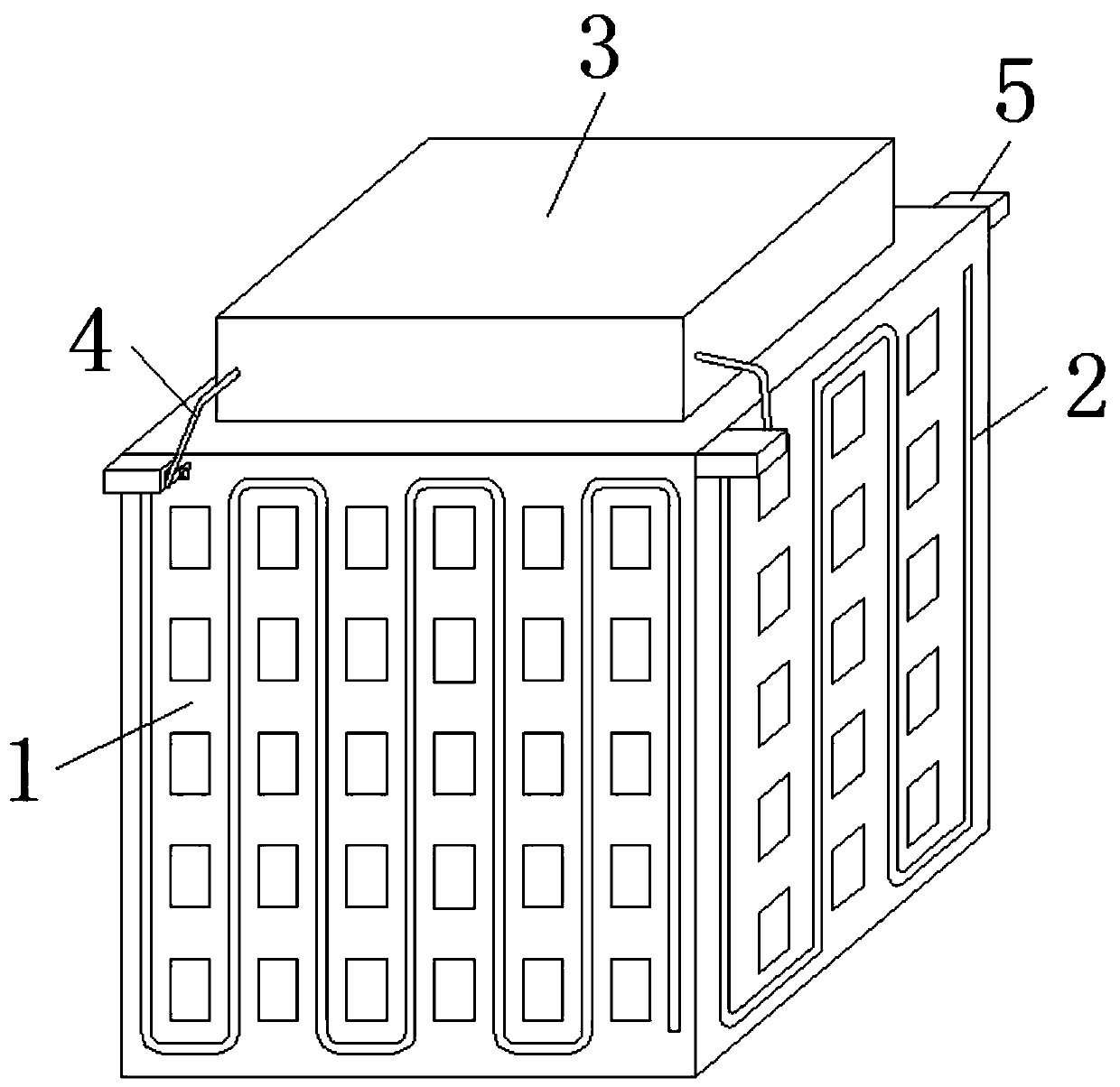

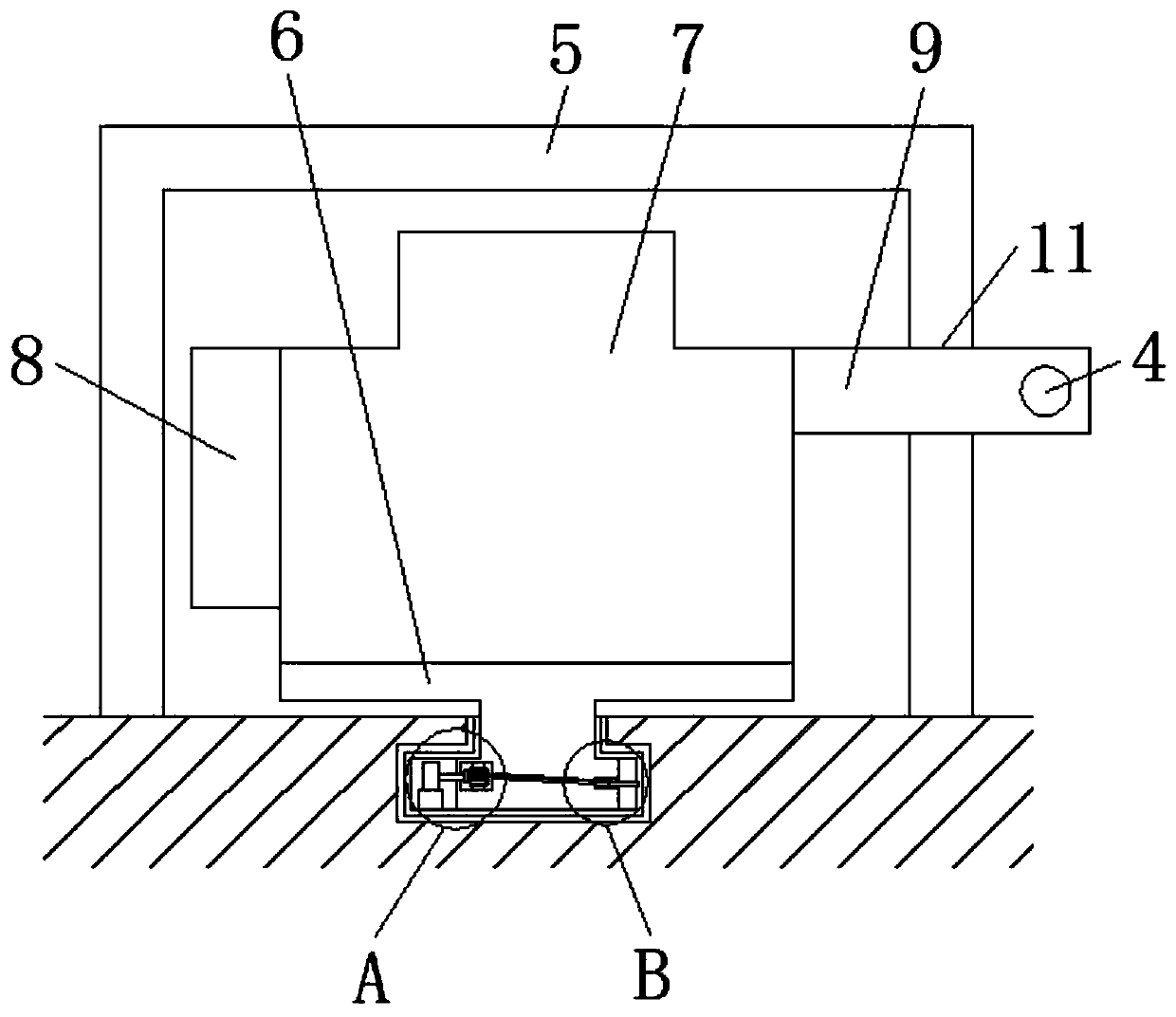

[0040] A building house fire fighting robot, such as figure 1 As shown, including the house main body 1, the surrounding surface of the house main body 1 is provided with stroke grooves 2, the top of the house main body 1 is fixedly connected with a water storage tank 3, and the surrounding surfaces of the water storage tank 3 are fixedly connected with a fire water pipe 4, and the house main body 1 The surface around the top of the top is fixedly connected with a protective frame 5, and the inner wall of the stroke groove 2 is provided with a moving device, and the moving device includes a robot mounting block 6;

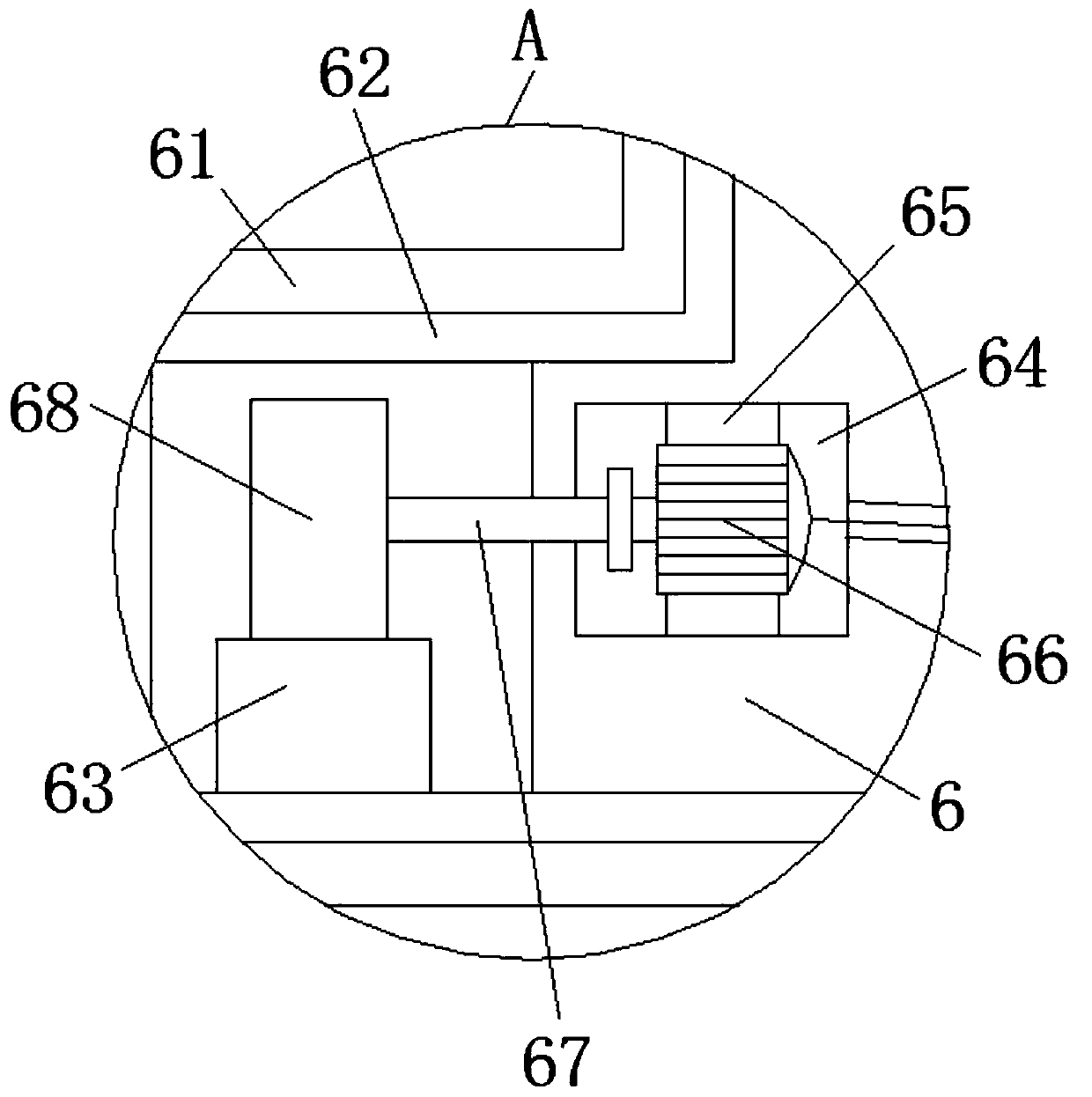

[0041] Such as image 3 and Figure 6 As shown, the inner wall of the travel groove 2 is fixedly connected with an insulating pad 61, and the surface of the insulating pad 61 is fixedly connected with a travel track 62. The power supply of the main body 1 is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com