Method for judging water leakage of washing machine and washing machine thereof

A washing machine and water level technology, applied in the field of washing machines, can solve problems such as alarm signal lag, user time waste, circuit system damage, etc., and achieve the effects of improving accuracy, saving time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

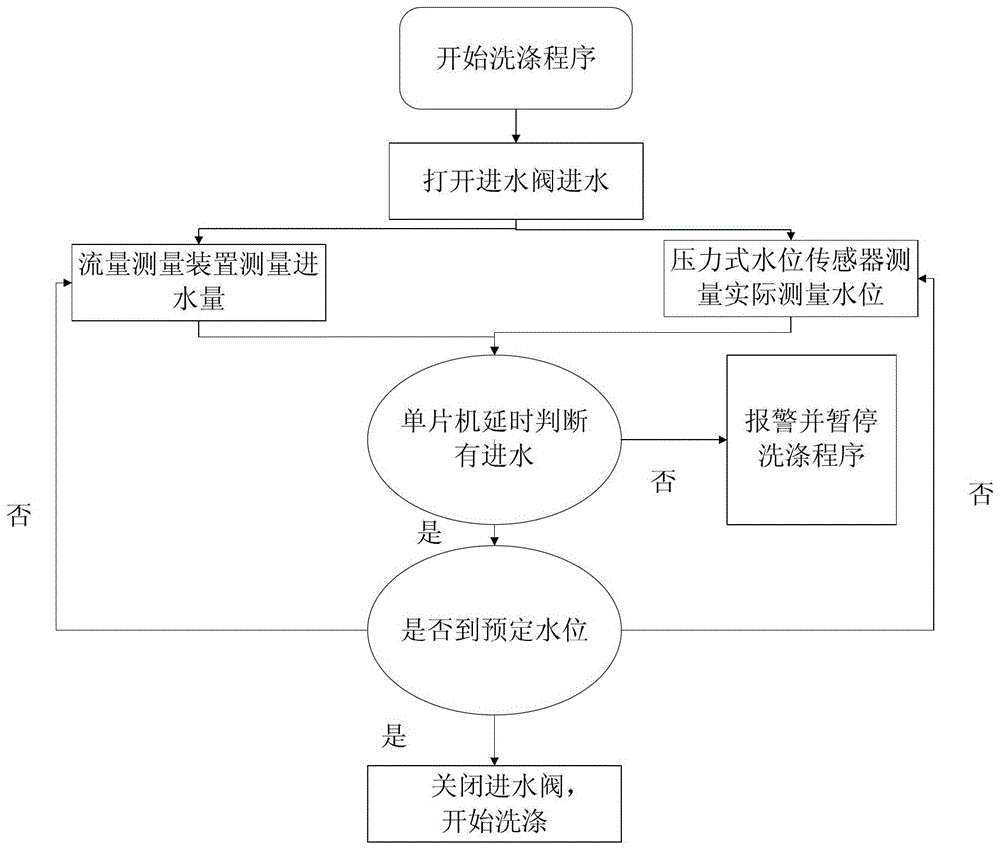

[0033] like figure 1 As shown, a method for judging water leakage of a washing machine in this embodiment specifically includes the following steps: detecting the real-time water inlet flow of the washing machine through the flow measuring device 2 arranged on the water inlet pipeline in the washing machine, and measuring the quality Q of the clothes by a weighing system ;Calculate the water inflow W in the washing machine through the real-time water inflow flow, and then combine the clothes quality Q and the structure analysis of the outer tub of the washing machine to calculate the calculated water level L1 in the outer tub of the washing machine; the calculated water level L1 in the outer tub of the washing machine and the actual water level L2 For comparison, if L1>L2, the control system 4 sends out a water leakage alarm signal.

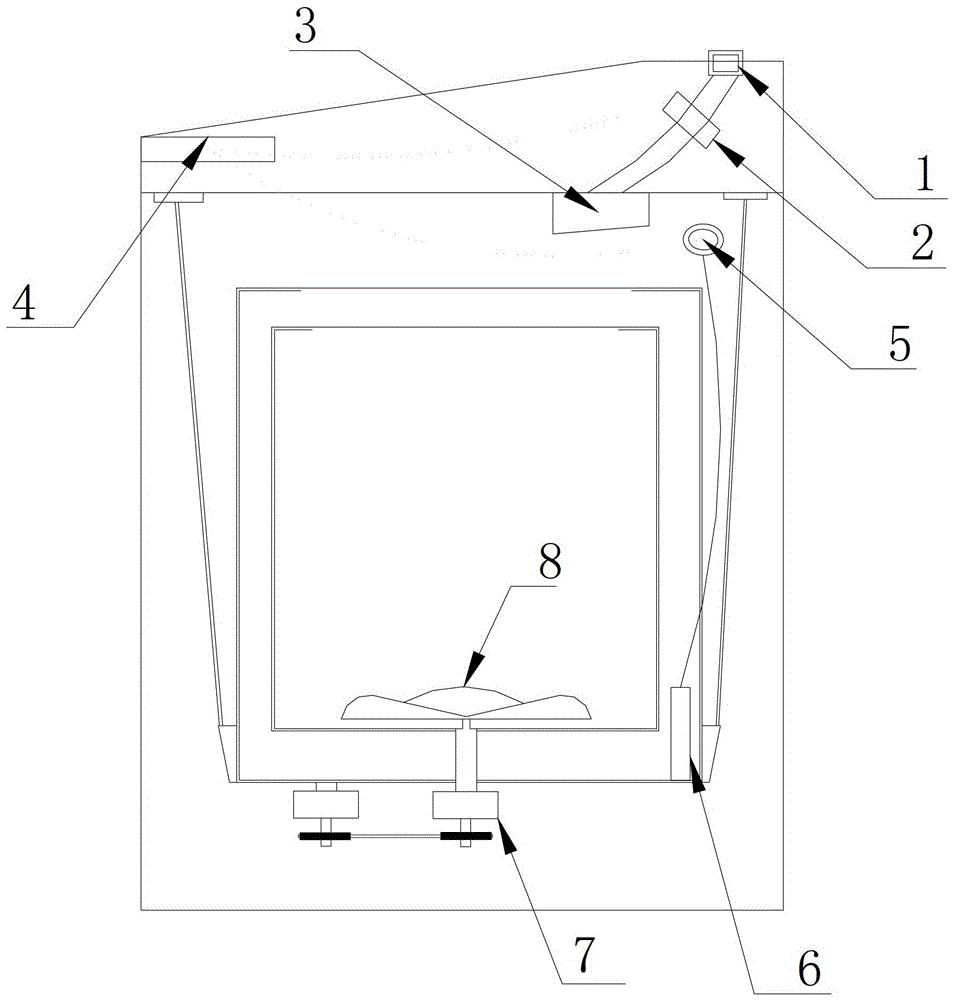

[0034] like figure 2 As shown, in this embodiment, a washing machine is applied with the above washing machine water level detection method, a...

Embodiment 2

[0041] like figure 1 As shown, the method in this embodiment includes: a method for judging water leakage of a washing machine: detecting the water intake W through the flow measurement device 2 arranged on the water inlet pipeline; the flow measurement device 2 transmits the water intake W to the control system of the washing machine 4. The control system 4 of the washing machine converts the water intake W into the calculated water level L1 in the outer tub of the washing machine, and compares the calculated water level L1 with the actual water level L2. If L1>L2, the control system 4 sends out The alarm signal is displayed to the user through the output terminal, and the washing program is suspended.

[0042] like Figure 4As shown, in the present embodiment, the water inflow W is detected by the following method: the flow of water inflowing into the outer tub of the washing machine in real time is detected by the flow measuring device 2 arranged on the water inlet pipelin...

Embodiment 3

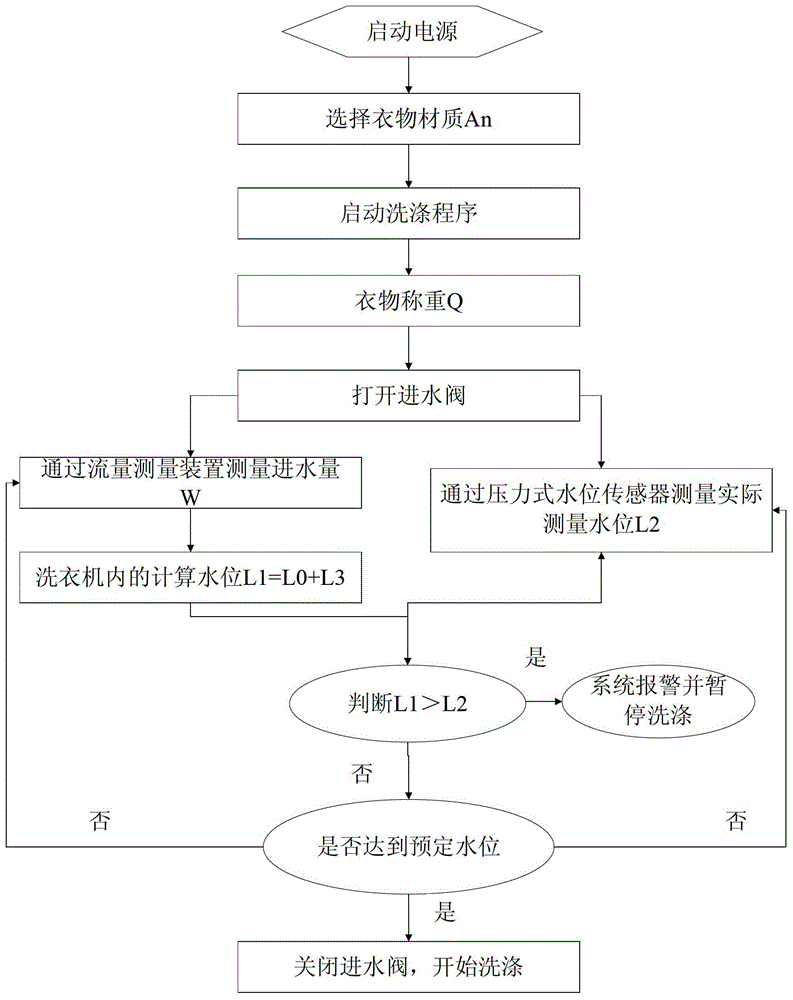

[0046] Such as image 3 As shown, in this embodiment, the revised water level L3 is a water level value correspondingly obtained by the control system according to the influence coefficient A and the weight Q of the clothes. The weight Q of the clothes is measured by the weighing system, and the measured weight Q of the clothes is transmitted to the control system. The said influence coefficient A is a revision value preset in the control system 4 . The influence coefficient A is divided into different coefficient values An according to different clothing materials, and the control system 4 selects the corresponding coefficient value An according to the clothing materials washed by the user, so as to obtain the revised water level corresponding to the clothing material and clothing weight Q L3.

[0047] When the washing machine uses the above method to wash clothes, and the clothes washed by the washing machine are clothes made of various materials, the control system 4 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com