A test method for the solid-liquidus temperature of steel samples

A technology of liquidus temperature and test method, applied in the investigation stage/state change and other directions, can solve the problems of metal volatiles easily contaminating the differential scanning calorimeter bracket, unable to provide accurate reference values, unable to meet production needs, etc. Achieve the effect of simple and accurate test method, protection of samples, and low requirements for equipment hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

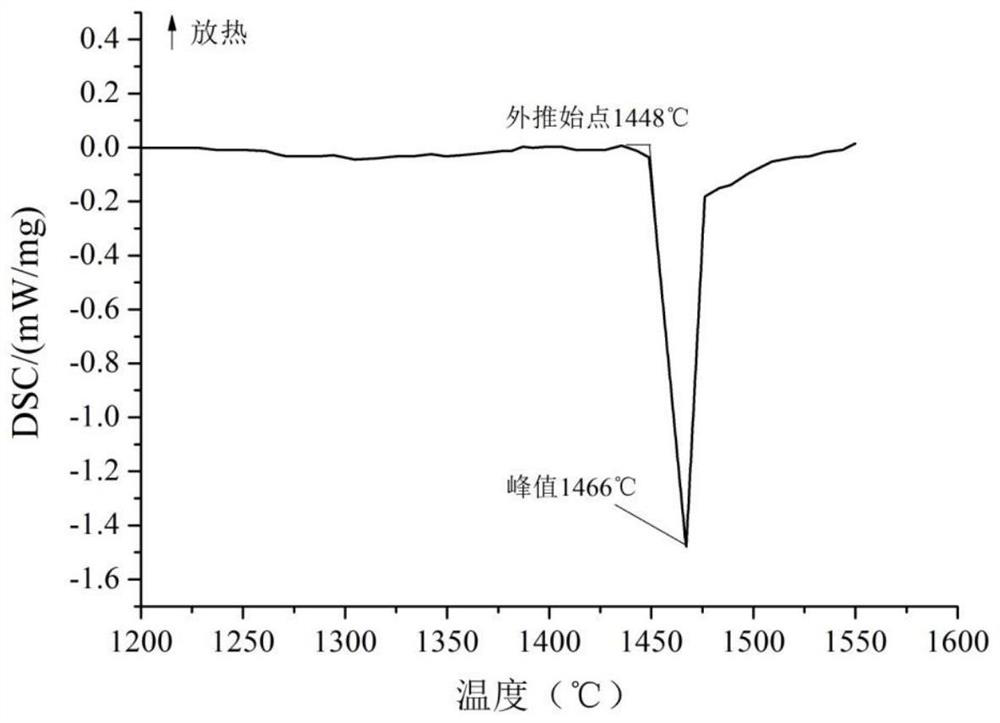

[0031] Select SWRH82A wire rod as the test sample to test its solid-liquidus temperature. The steps are as follows:

[0032] (1) Cut out several 5mg granular samples;

[0033] (2) Clean the oxide skin and pollutants on the surface of the sample, and use a cleaning solution to clean it for 3 minutes at a temperature of 20-30°C to ensure that the oxide skin and pollutants on the surface of the sample are cleaned. The composition of the cleaning solution is as follows: 30-35mL of hydrochloric acid, 20-25mL of sulfuric acid, 12-14mL of ethanol, 0.2-0.3g of hexamethylenetetramine, 24-29mL of hydrogen peroxide, and 10-50mL of distilled water. Soak the cleaned sample in gasoline for 2 minutes, take it out and dry it to prevent the sample from rusting;

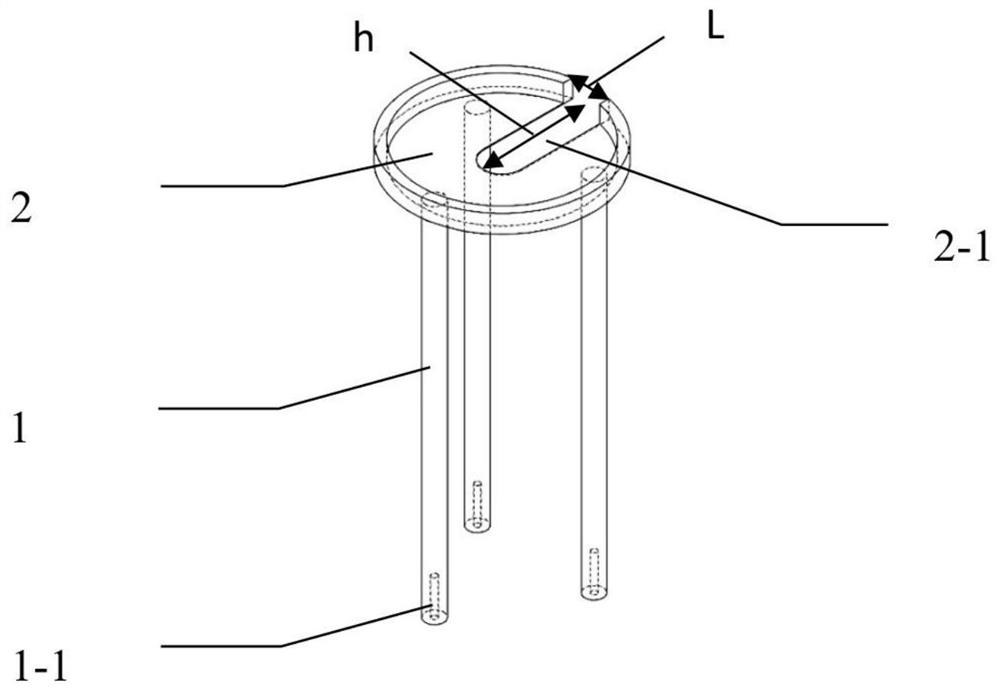

[0034] (3) Open the furnace of the differential scanning calorimeter to expose the bracket and the heat sink, install the residual oxygen elimination device into the upper end of the heat sink of the equipment, and spread the sponge zi...

Embodiment 2

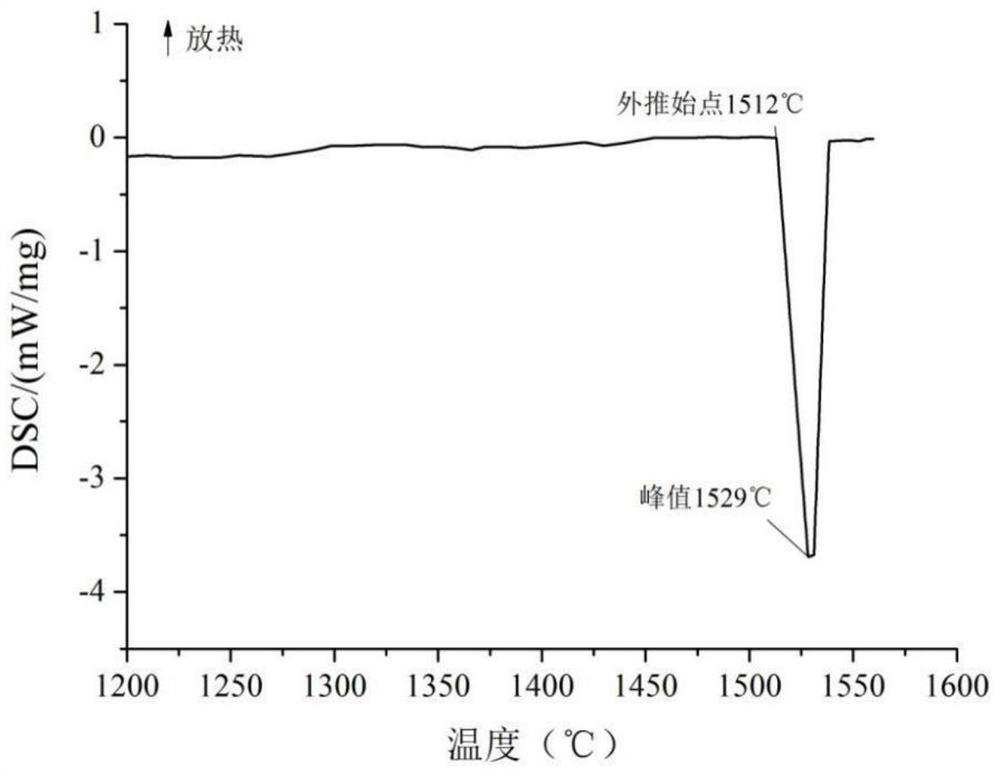

[0039] To test the solid-liquidus temperature of W800 silicon steel sheet, the steps are as follows:

[0040] (1) Cut several 10mg granular samples;

[0041] (2) Clean the oxide skin and pollutants on the surface of the sample, and use a cleaning solution to clean it for 5 minutes at a temperature of 20-30°C to ensure that the oxide skin and pollutants on the surface of the sample are cleaned. The composition of the cleaning solution is as follows: 30-35mL of hydrochloric acid, 20-25mL of sulfuric acid, 12-14mL of ethanol, 0.2-0.3g of hexamethylenetetramine, 24-29mL of hydrogen peroxide, and 10-50mL of distilled water. Soak the cleaned sample in gasoline for 3 minutes, take it out and dry it to prevent the sample from rusting;

[0042] (3) Open the furnace chamber of the differential scanning calorimeter, expose the support and heat sink, take out the old zirconium sponge in the circular tray 2, and replace it with an appropriate amount of zirconium sponge;

[0043] (4) Wrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com