A kind of high-efficiency sedimentation method of waste slurry in concrete batching plant

A mixing station and concrete technology, which is applied in the field of high-efficiency settlement of waste slurry in concrete mixing stations, can solve the problems of large area of processing equipment, low water utilization rate of waste slurry, low solid content of settled slurry, etc., and achieve low production cost, The effect of low energy consumption and enhanced dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

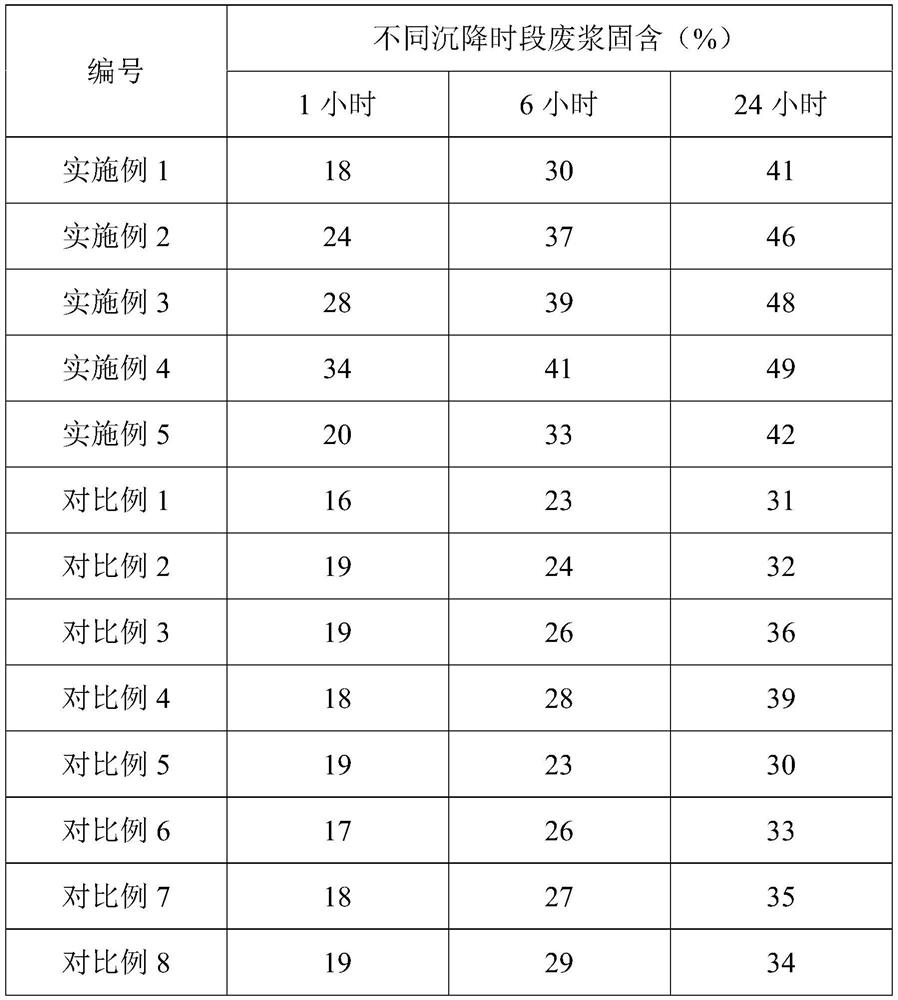

Embodiment 1

[0029] In this example, take 200kg of waste pulp with a solid content of 15wt%, add 0.1kg of polyethylene glycol monomethyl ether and 0.05kg of acrylic acid-isoamyl polyoxyethylene ether copolymer, and stir at 200rpm for 2 minutes. Add 1 kg of anionic polyacrylamide with a mass concentration of 0.1% and a molecular weight of 6 million g / mol, and 0.2 kg of sodium polyacrylate with a mass concentration of 0.1% and a molecular weight of 2 million g / mol, respectively, stir at a speed of 60 rpm for 6 minutes and then let it settle. , suck out the upper layer of clear water after settling for 1 hour, 6 hours and 24 hours, respectively, and take 200g of waste pulp to test the solid content.

Embodiment 2

[0031] In this example, take 200kg of waste pulp with a solid content of 20wt%, add 0.1kg of polyethylene glycol monomethyl ether monophosphate and 0.05kg of acrylic acid-maleic anhydride-methallyl polyoxyethylene ether copolymer, respectively, at 300 rpm Stir at a rotational speed for 2 minutes. After stirring, add 1 kg of anionic polyacrylamide with a mass concentration of 0.1% and a molecular weight of 8 million g / mol and 0.2 kg of sodium polyacrylate with a mass concentration of 0.1% and a molecular weight of 3 million g / mol. After stirring for 8 minutes at the rotating speed, it was left to settle, and after settling for 1 hour, 6 hours, and 24 hours, the upper layer of clear water was sucked out, and 200 g of waste pulp was taken to test the solid content.

Embodiment 3

[0033] In this example, take 200 kg of waste pulp with a solid content of 25 wt%, add 0.2 kg of maleic anhydride polyethylene glycol monomethyl ether monoester and 0.06 kg of maleic anhydride-allyl polyoxyethylene ether copolymer, and stir at 400 rpm. For 1 minute, after stirring, add 2kg of dimethyl diallyl ammonium chloride-acrylamide copolymer with a mass concentration of 0.1% and a molecular weight of 8 million g / mol and a polymer with a mass concentration of 0.1% and a molecular weight of 3 million g / mol. Potassium acrylate 0.4kg, stirred at 60rpm for 8 minutes and then left to settle, suck out the upper layer of clear water after 1 hour, 6 hours and 24 hours of sedimentation respectively, and take 200g of waste pulp to test the solid content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com