Workpiece machining conveying disc and workpiece machining conveying mechanism using workpiece machining conveying disc

A technology of conveying mechanism and conveying disc, which is applied in the direction of metal processing equipment, manufacturing tools, grinding machine parts, etc., to achieve effective adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

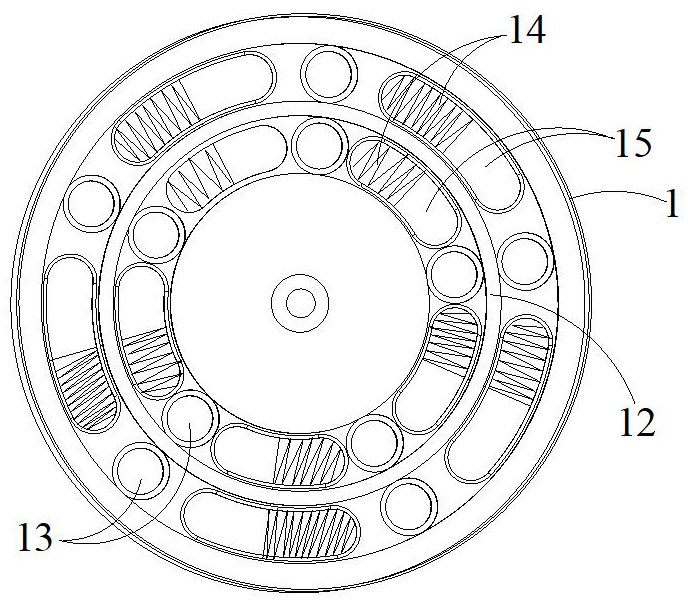

[0038] see Figure 1 to Figure 4 As shown, this embodiment provides a workpiece processing conveying tray, including: a disc-shaped processing disc 1 suitable for circular motion and at least one annular structure recessed on the disc-shaped processing disc 1 The processing and discharging unit; here, the processing and discharging unit is synchronously driven to perform circular motion during the circular motion of the disc-shaped processing disc 1, so that the workpiece 2 processed by the processing and discharging unit can be placed on the disc-shaped processing disc 1 The transfer of the workpiece 2 is realized during the circular motion.

[0039] The processing and discharging unit of this embodiment includes several concave arc-shaped processing tanks 11 distributed at intervals along the circumferential direction, and a through-disc-shaped processing tank provided between every two adjacent arc-shaped processing tanks 11. The discharge port 13 of the disc 1; that is to...

Embodiment 2

[0055] On the basis of the workpiece processing conveying tray in Embodiment 1, the workpiece processing conveying tray provided in this embodiment has the same general structure as that in Embodiment 1, except that in this embodiment, the grinding treatment structure provided in the grinding area 14 adopts, for example, But not limited to abrasive discs or sandpaper; and the adsorption treatment structure provided in the adsorption area 15 adopts paste paraffin. After the grinding treatment structure and the adsorption treatment structure are assembled in place in the arc-shaped treatment tank 11, the grinding treatment structure and the adsorption treatment structure at this time are flush with the end face of the workpiece 2 facing the discharge port 13, so that the workpiece 2 is polished and powdered. After the particle is adsorbed, it can smoothly enter the discharge port 13 along with the circular motion of the disc-shaped processing disc 1, without the situation that th...

Embodiment 3

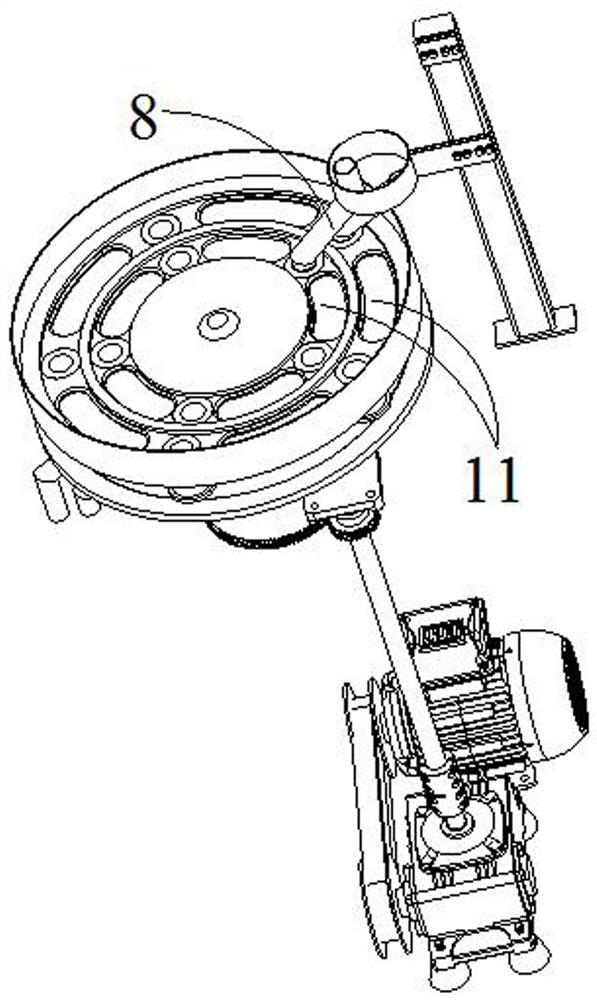

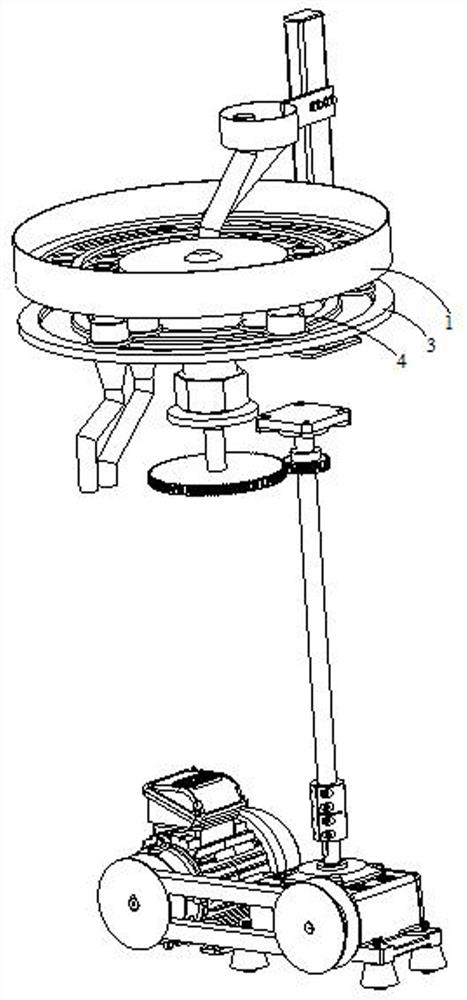

[0058] see Figure 1 to Figure 8 As shown, on the basis of the workpiece processing conveying plate in embodiment 1 or embodiment 2, this embodiment provides a workpiece processing conveying mechanism, including: the workpiece processing conveying plate in embodiment 1 or embodiment 2, and the disc The disc-shaped processing disc 1 is coaxially arranged on the disc-shaped discharge disc 3 below the disc-shaped process disc 1, and between the disc-shaped process disc 1 and the disc-shaped discharge disc 3 and the discharge port 13 one by one Corresponding feed pipe 4. It should be noted that the feed pipe 4 here is fixedly connected with the end face of the disc-shaped processing tray 1 facing the disc-shaped discharge tray 3, and the feed pipe 4 itself and the disc-shaped discharge tray 3 are in contact with each other. Fitting or direct non-contact but a small gap exists, because even a small gap will not affect the entry of the workpiece 2 into the discharge port 13, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com