High-reaming high-plasticity 980MPa-grade cold-rolled continuously-annealed steel plate and preparation method thereof

A 980mpa, high plasticity technology, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as increasing the cost of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below by embodiment the present invention will be further described.

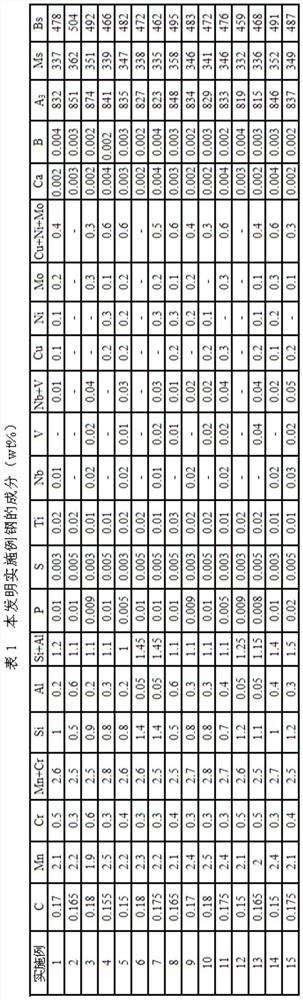

[0057] In the embodiment of the present invention, smelting, hot rolling, pickling, cold rolling, continuous annealing and skin pass are carried out according to the component ratio of the technical solution.

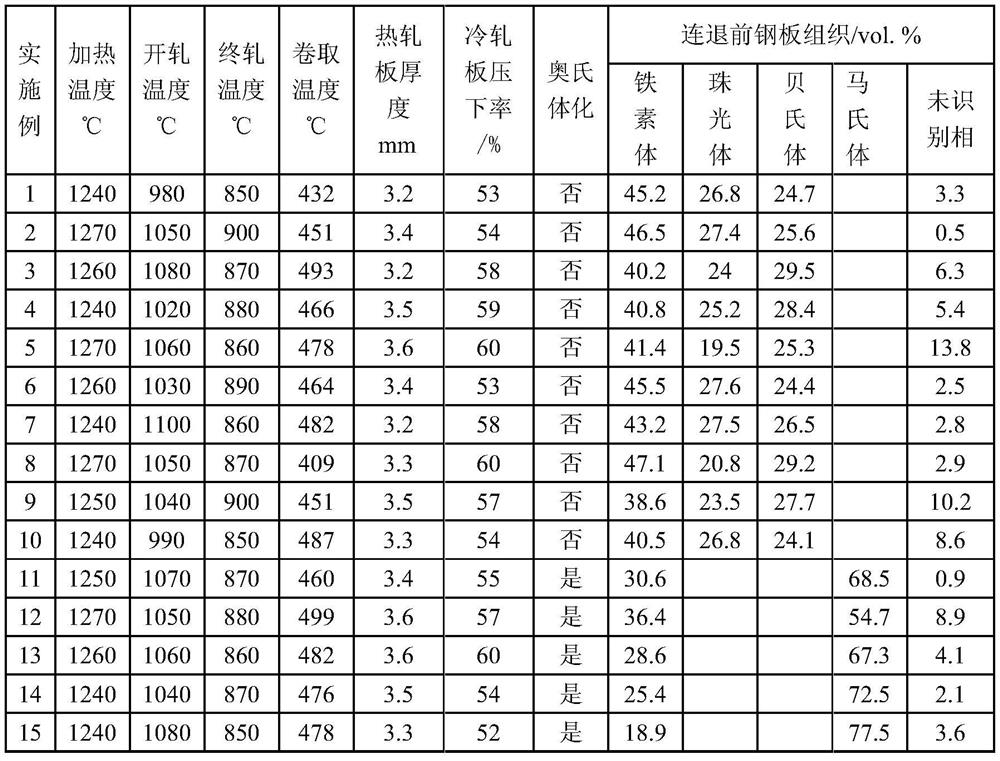

[0058] (1) Hot rolling:

[0059] The heating temperature is between 1240-1270°C, and isothermal for more than 2 hours; the starting rolling temperature is 950-1100°C, and the final rolling temperature is above 850°C; the coiling temperature is 400-500°C; the thickness of the hot-rolled coil is 3.2-3.6mm;

[0060] (2) Cold rolling:

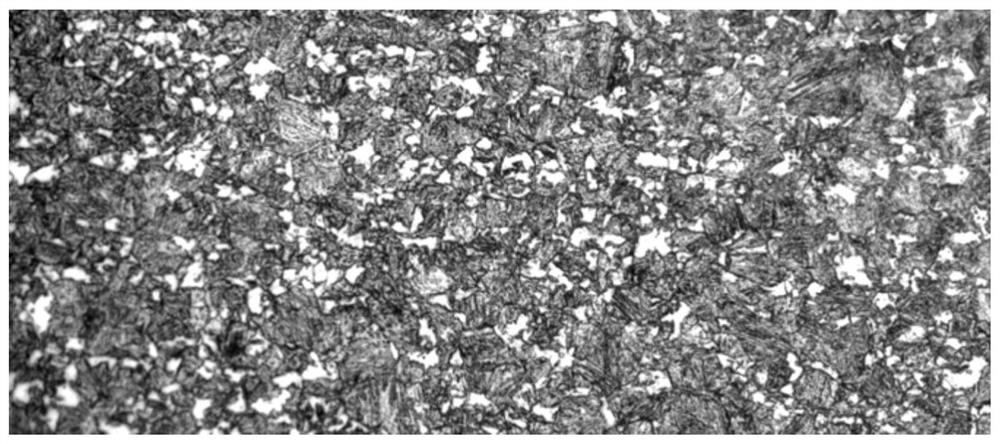

[0061] The structure after cold rolling includes ferrite, pearlite, and bainite, and the microstructure of the steel plate after cold rolling is as follows according to the volume percentage: Tensile body: 23% to 30%.

[0062] (3) Continuous withdrawal:

[0063] The heating isothermal temperature is 810-870°C, the isothermal time is 60-240s, the slow cooling te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com