Section steel support and cover plate fabricated foundation for a frozen earth area.

A prefabricated, profiled steel technology, applied in infrastructure engineering, construction, etc., can solve the problems of large friction coefficient of concrete surface, limited bottom area of support section, displacement of concrete slats, etc., and achieve low surface friction coefficient and large inclination angle. , the effect of easy transportation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below.

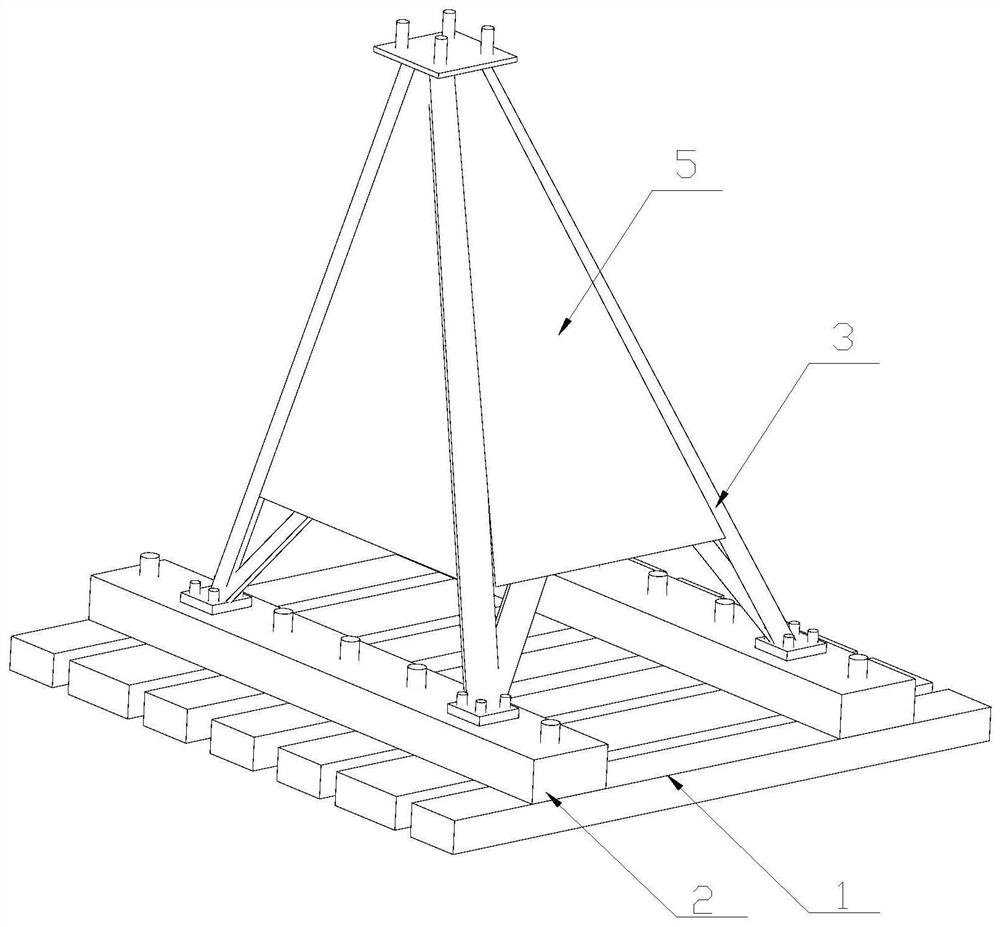

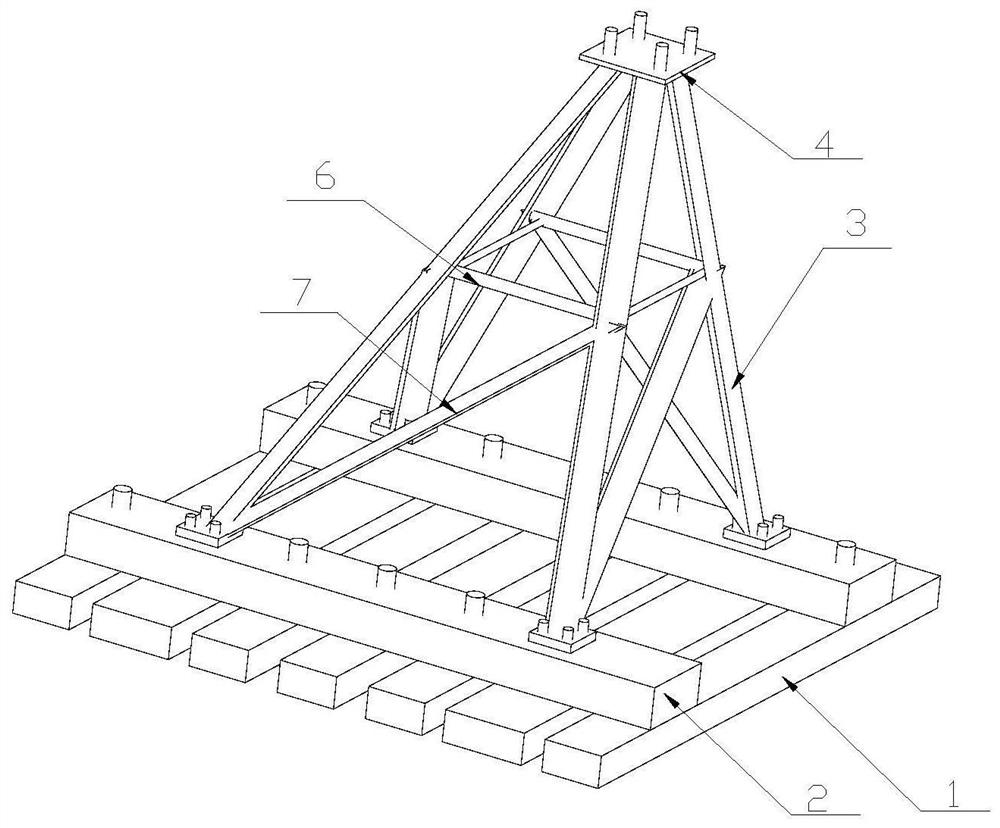

[0020] The assembled foundation for the sectioned steel support cladding plate in the permafrost area disclosed by the present invention includes a base plate slat 1 and a base plate connecting beam 2, a plurality of the base plate slats 1 are arranged in parallel, and the base plate connecting beam 2 is vertically connected to the base plate On the slat 1, the bottom plate connecting crossbeam 2 is provided with a shaped steel bracket, the shaped steel bracket includes at least three main materials 3, and each main material 3 forms an oblique cone structure, and the bottom of the main materials 3 of the shaped steel bracket is dispersedly connected On the connecting beam 2 of the bottom plate, the top of the main material 3 of the shaped steel bracket is converged and connected with the connecting seat plate 4 for connecting the foot plate of the iron tower. The surface friction coefficients of the steel bracket and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com