Outer wall hole plugging formwork and outer wall hole plugging method

A technology for sealing templates and external walls, which is applied in the fields of formwork/formwork/work frame, building maintenance, and on-site preparation of building components. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

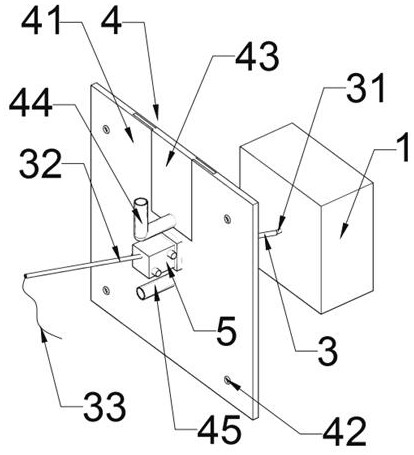

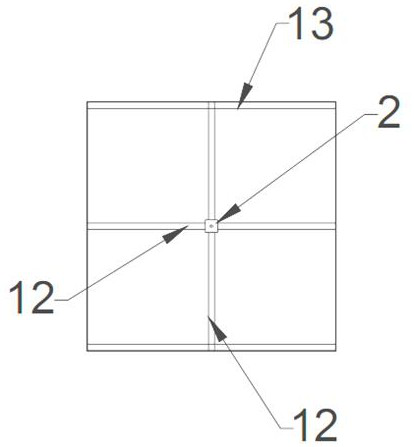

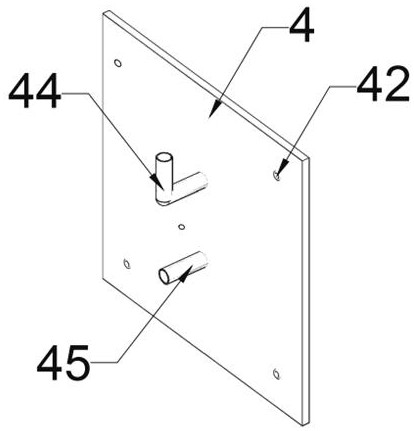

[0022] Such as figure 1As shown, the exterior wall hole sealing formwork provided in this embodiment includes exterior wall formwork 1 and interior wall formwork 4 arranged at intervals, the exterior wall formwork 1 is a flexible airbag with an inflatable cavity inside, and the exterior wall formwork 1 After being inflated, it is in the shape of a cube. An inflatable nozzle 2 is provided on the side of the exterior wall formwork 1 facing the interior wall formwork 4. An inflatable tube 3 for inflating the exterior wall formwork 1 is detachably connected to the inflatable nozzle 2. The inflatable tube 3 is a rigid tube, and its end is inclined upward; the interior wall formwork 4 is vertically arranged, and a grout discharge pipe 44 and a grouting pipe 45 passing through the interior wall formwork 4 are arranged at intervals up and down on the front end of the interior wall formwork 4 After the end of the inflation pipe 3 passes through the interior wall formwork, it is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com