A mechanical sealing arrangement and a sensor ring for monitoring the operation of a mechanical seal arrangement

A layout structure and mechanical seal technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of difficult access to mechanical seals, no monitoring, etc., and achieve the effect of improving reliability and/or predictability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

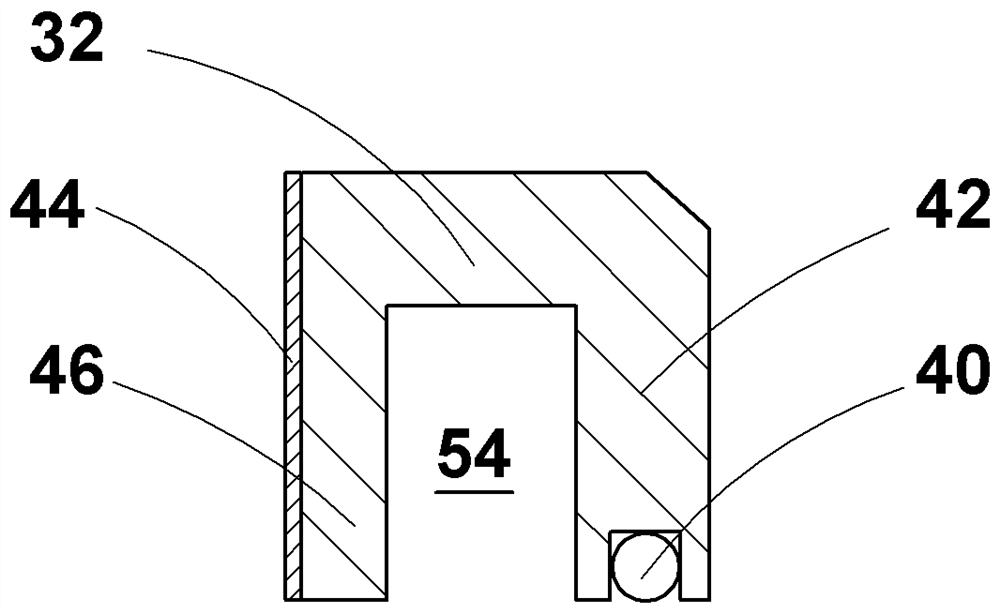

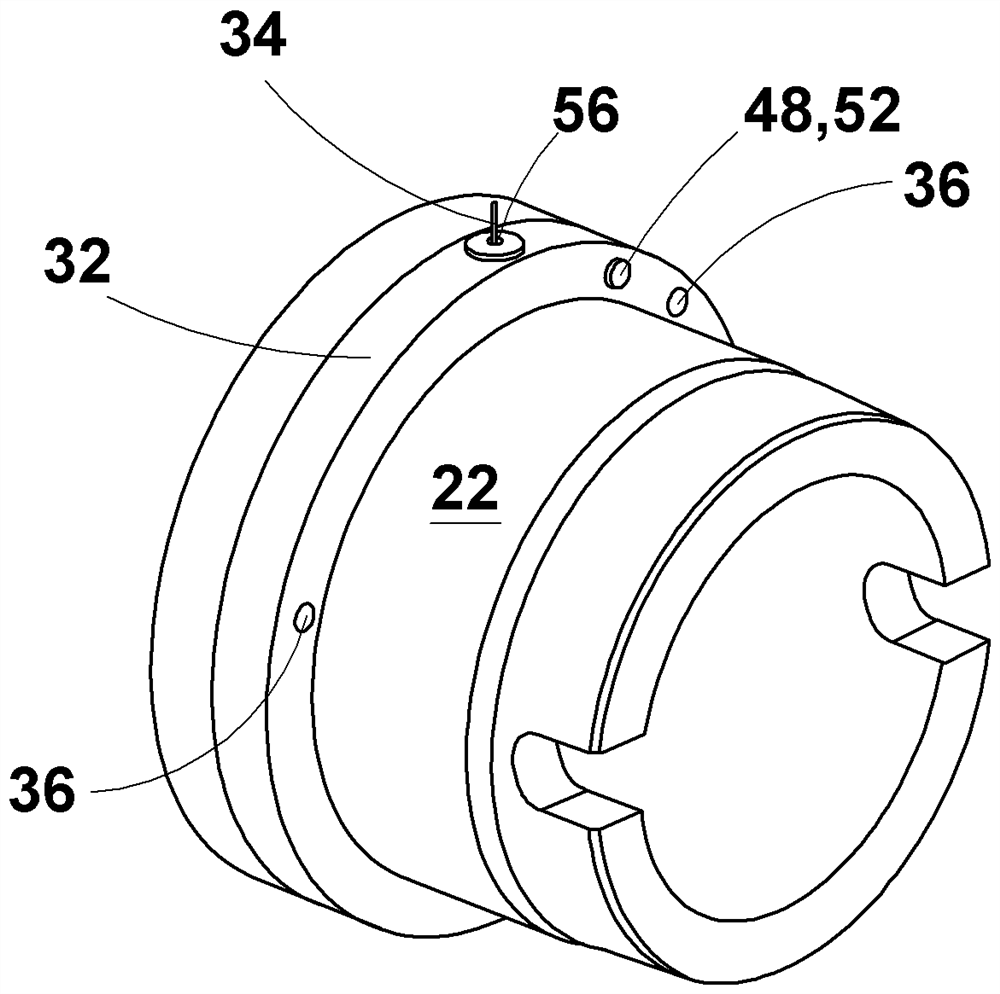

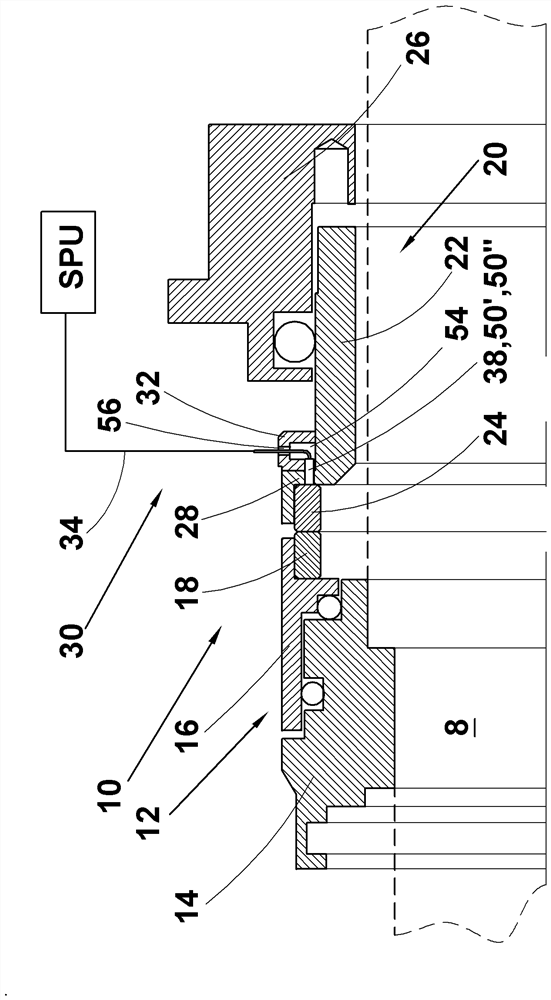

[0038]figure 1 A mechanical seal arrangement according to a preferred embodiment of the present invention is depicted, comprising a schematically and exemplarily shown single acting mechanical seal 10 and a signal processing arrangement 30 . The invention is of course also applicable to double-acting mechanical seals. A mechanical seal 10 is used to seal, for example, the shaft 8 of a draft machine (shown in dashed lines) such that the interior of the draft machine (at the left hand side of the seal 10 ) is kept from the atmosphere (at the right hand side of the seal 10 ) separate. The mechanical seal 10 is located in a seal chamber provided within a particular seal housing or within the housing cover of the flow generator.

[0039] The mechanical seal 10 includes a rotating portion 12 and a non-rotating portion 20 . The rotating part 12 includes a retainer ring 14 , a rotating slip ring bracket 16 and a rotating slip ring 18 . A rotary slip ring 18 is attached to an axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com