Method for producing a traction battery of a motor vehicle

A technology for traction batteries and automobiles, applied to batteries, electric vehicles, secondary batteries, etc., to reduce or limit the installation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

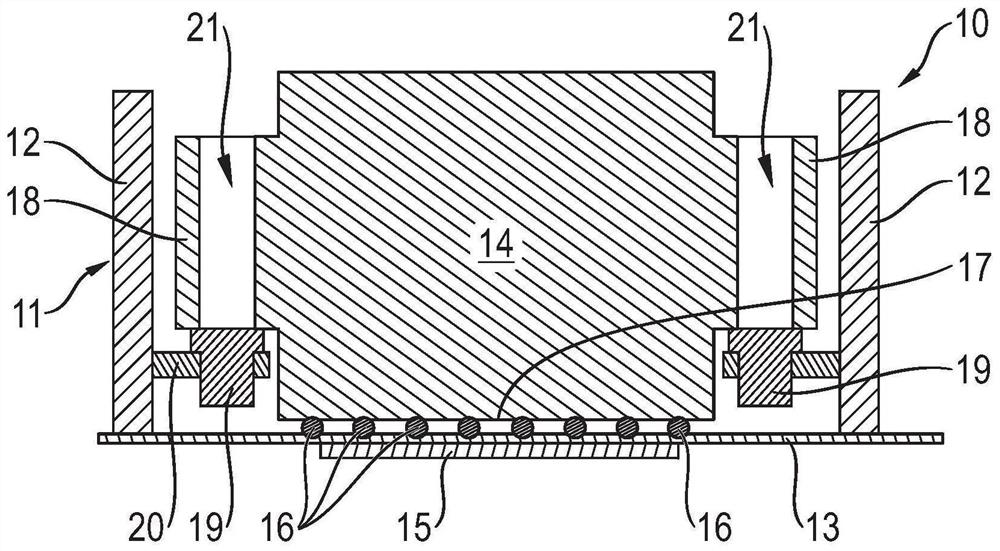

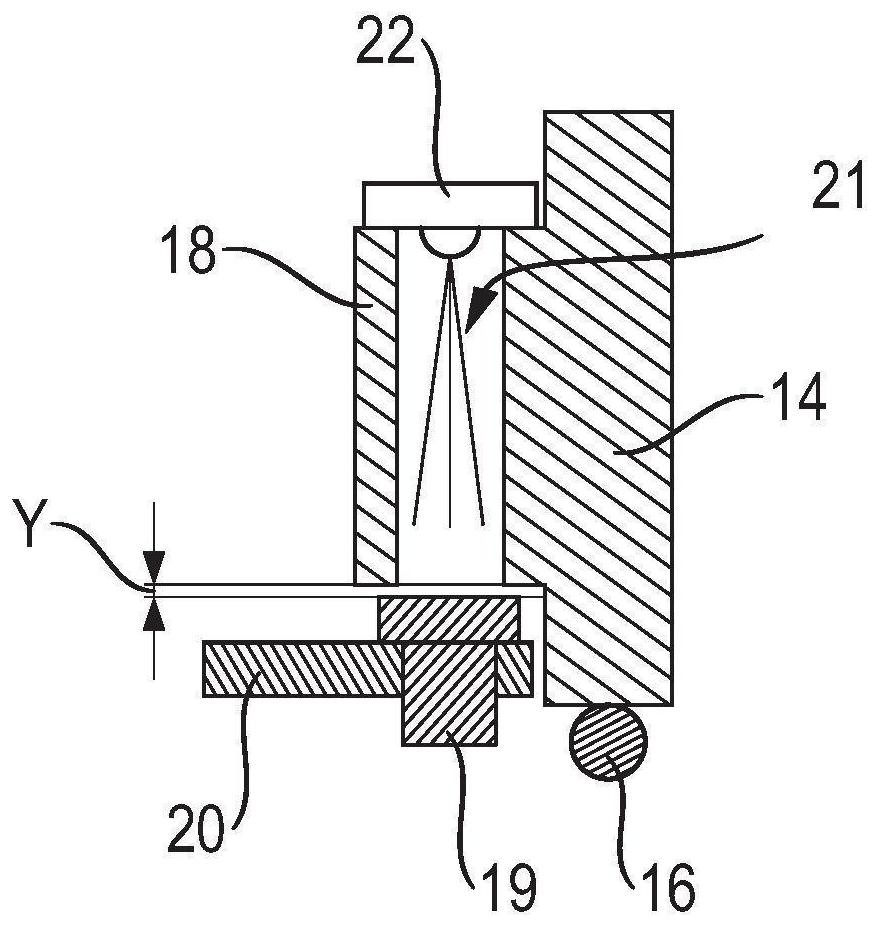

[0024] figure 1 It is a schematic partial cross-sectional view of a traction battery 10 of a motor vehicle. The traction battery 10 has a housing 11 formed from side walls 12 and a bottom wall 13 . Additionally, the housing can have figure 1 Top wall or cover not shown.

[0025] The housing has a plurality of receiving areas for the battery modules 14, wherein, for the sake of clarity, in figure 1 Only one such receiving chamber is shown in FIG. 2 , in which a battery module 14 is installed. The receiving area is at least partially delimited by side walls 12 and a bottom wall 13 .

[0026] The bottom wall 13 of the housing 11 of the traction battery 10 is a cooled bottom wall 13 , wherein figure 1 A cooling device 15 for cooling the bottom wall 13 is shown very schematically. Typically, the bottom wall 13 is flowed through by the coolant and thus has flow channels for the coolant. In this case, the cooling channels through which the coolant flows then form the cooling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com