Electric vehicle electronic wire harness gathering and battery heat dissipation storage structure

A technology of electronic wires and electric vehicles, applied in electric vehicles, battery/battery traction, vehicle energy storage, etc., can solve the problems of no heat dissipation space for batteries, cracked wiring harness skins, and additional batteries, so as to avoid cumbersome situations and facilitate disassembly Effects of maintenance and service life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

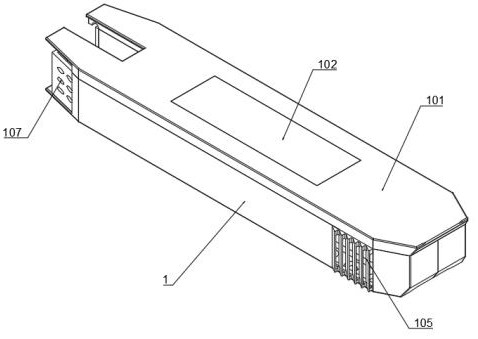

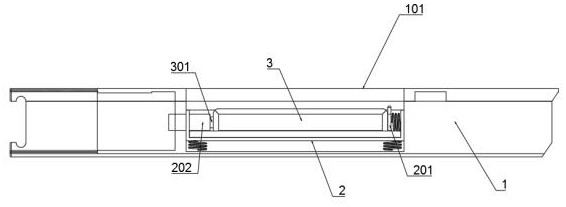

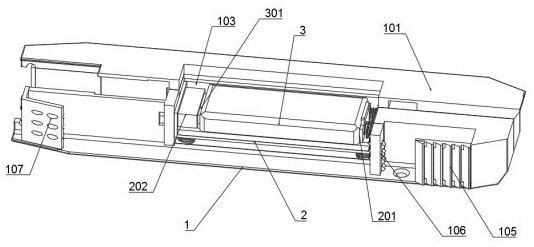

[0036] as attached figure 1 to attach Figure 10 Shown:

[0037]The present invention provides a storage structure for electric vehicle electronic wiring harness gathering and battery heat dissipation, comprising: a storage case 1; Both sides of the bottom of the rectangular slot are exhaust slots, the rear end of the storage case 1 is the cable storage area, the cable storage area of the storage case 1 is located directly behind the rectangular slot of the storage case 1, and the front positions on both sides of the storage case 1 are set There is an air inlet, and three penetrating tapered grooves are symmetrically opened on both sides of the front end of the bottom of the storage case 1; the storage case 1 includes: a side plate 103, and two side plates 103 are symmetrically arranged on both sides of the rectangular slot of the storage case 1; Groove 104, the middle position of the rear end of the rectangular slot of the storage case 1 is provided with a wire harness gr...

Embodiment 2

[0043] Based on the reserve structure for bringing together the electric vehicle electronic harness and battery heat dissipation provided in the first embodiment, when the energy supply battery 3 is installed inside the placement part 2, when the storage case 1 is vibrated, The placement part 2 and the energy supply battery 3 will vibrate synchronously, which will affect the life of the energy supply battery 3. Based on the above situation, there are rubber strips on both sides of the bottom of the placement part 2, and a place on the four corners of the bottom of the placement part 2. The spring, the placement part 2 is located in the rectangular groove of the storage case 1 as a whole, and the four springs at the bottom of the placement part 2 are fitted to the bottom of the rectangular slot of the storage case 1 to supply the energy. It is connected in the rectangular socket 202, and the energy supply battery 3 is located in the middle of the placement part 2 as a whole, and...

Embodiment 3

[0046] Based on the reserve structure for bringing together the electronic harness of an electric vehicle and battery heat dissipation provided in the second embodiment, although the energy supply battery 3 inside the storage case 1 is used for shock absorption and buffering, the active force received by the storage case 1 is prevented from interacting with the energy supply battery 3 In the event of a collision, the energy supply battery 3 does not provide the ability to dissipate heat and ventilate the energy supply battery 3 during long-term use.

[0047] Based on the above circumstances, if the attached Figure 6 As shown, the storage case 1 includes: an air inlet plate 105, and there are two air inlet plates 105. The two air inlet plates 105 are respectively arranged at the air inlet positions at the front ends of both sides of the storage case 1, and the middle of the air inlet plate 105 The partition plate is inclined; filter plate 106, two filter plates 106 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com