Vehicle anti-skid control method and system

A control method and technology for a control system, applied in the field of vehicle engineering, can solve the problems of high cost, low system work efficiency, increased hydraulic system heat generation, etc., and achieve the effects of reducing heat generation, reducing cost, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

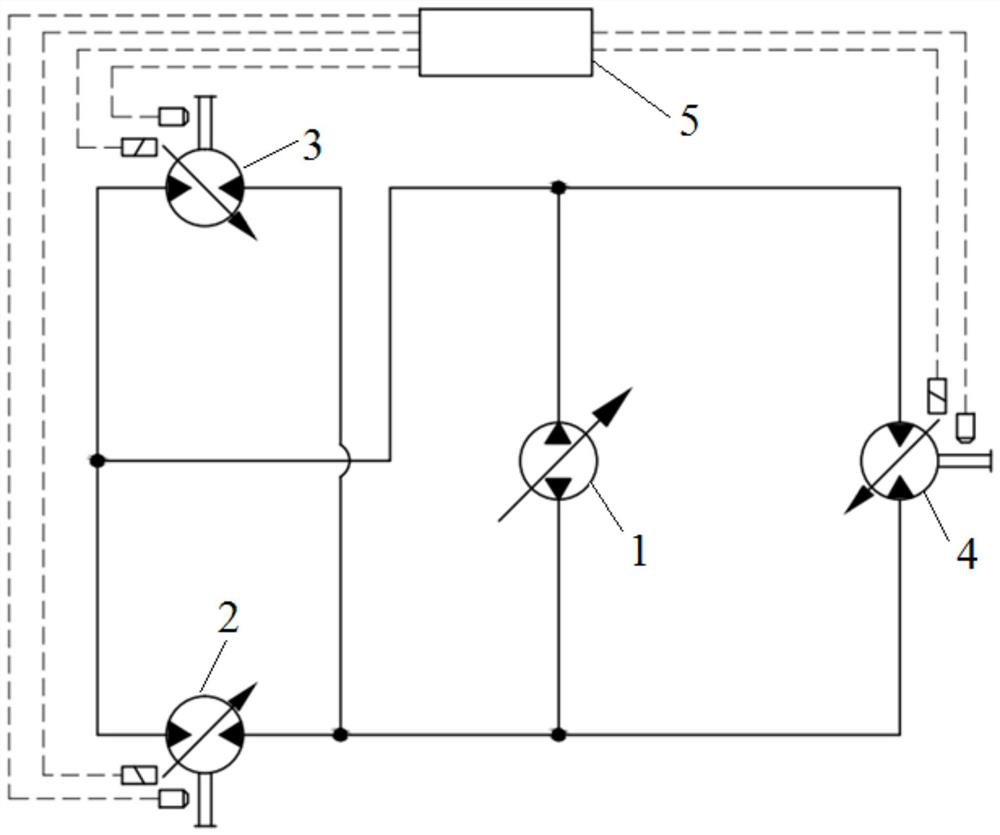

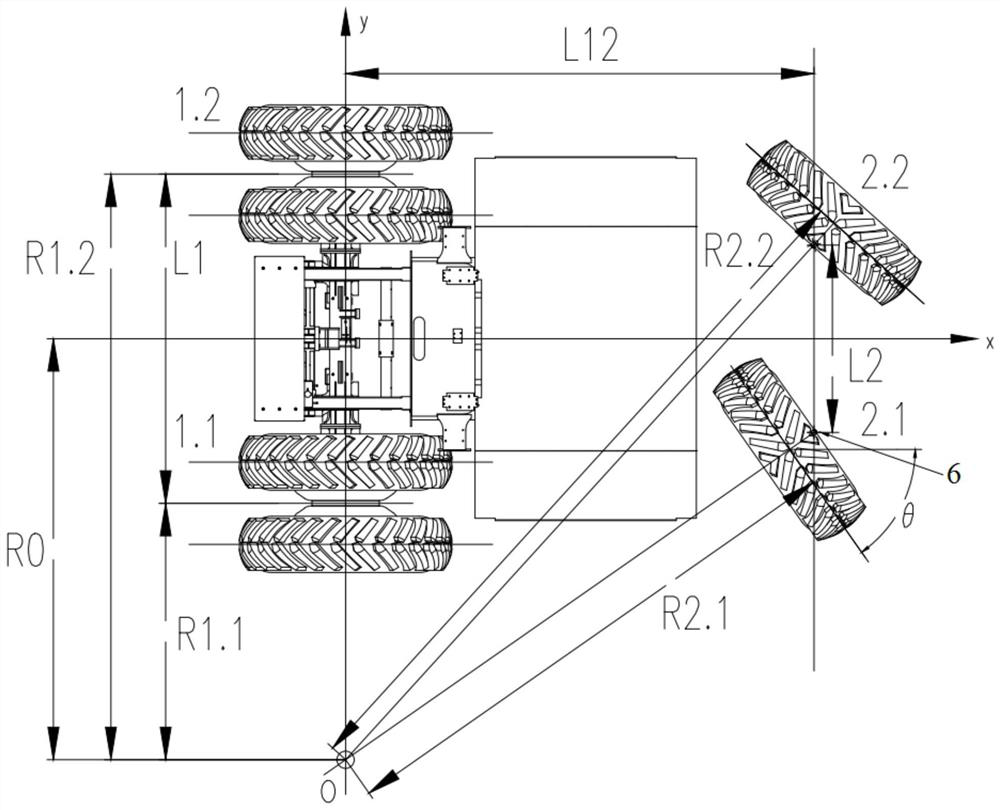

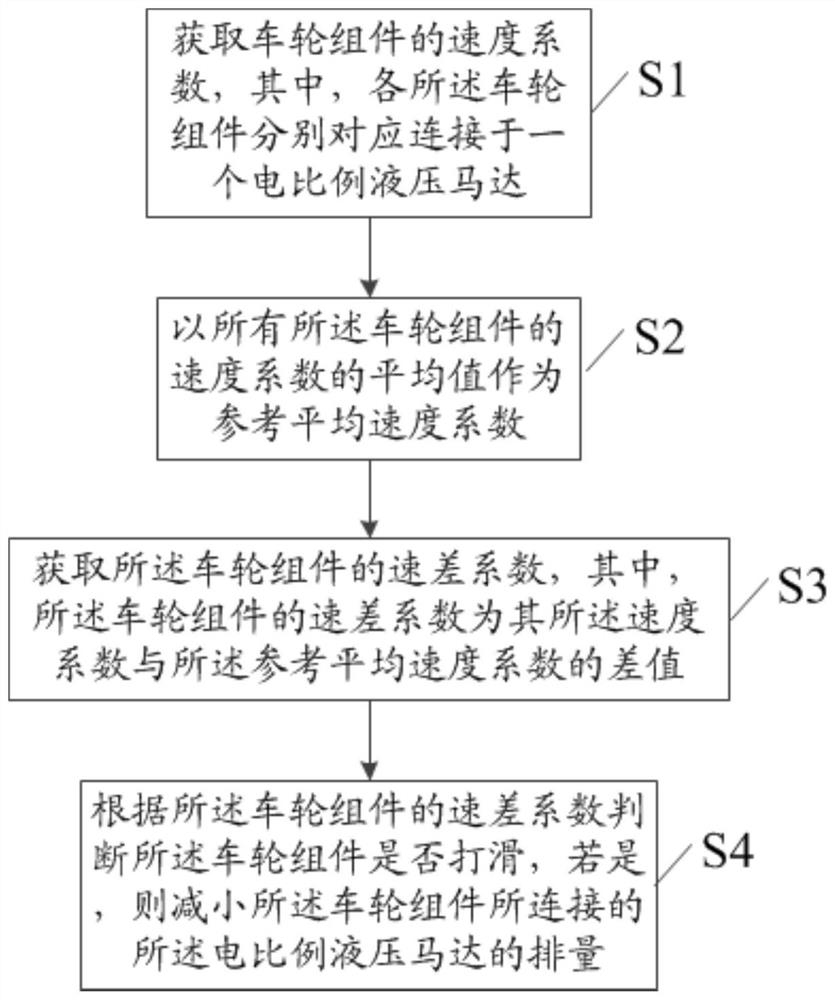

Method used

Image

Examples

specific Embodiment 2

[0104] Of course, in other embodiments, the step of determining the preset slip condition corresponding to the wheel assembly in accordance with the size relationship of the reference average speed coefficient and the preset low speed speed coefficient. DETAILED DESCRIPTION OF THE INVENTION

[0105] The comparison reference average speed coefficient and the preset low speed speed coefficient, when the current is large, the corresponding first slip rate is selected as the allowable sliding rate, otherwise, each wheel assembly selects the corresponding second slip rate as a corresponding second slip rate. Allow slip rate;

[0106]The preset slip condition corresponding to the wheel assembly is that the speed difference coefficient of the wheel assembly is greater than the corresponding allowable sliding rate, and if so, the wheel assembly satisfies the corresponding preset slip condition.

[0107] That is, in the second embodiment, after determining the vehicle speed, the speed diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com