An assembly structure and assembly method of a double-assist mechanism of a recirculating ball steering gear

An assembly method and steering gear technology, applied to steering mechanisms, electric steering mechanisms, power steering mechanisms, etc., can solve the problems of metal worm gears with large noise, inability to carry large torque, and single structural form, so as to meet the requirements of vehicle assembly and Clearance requirements, reduced output torque requirements, and reduced motor dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

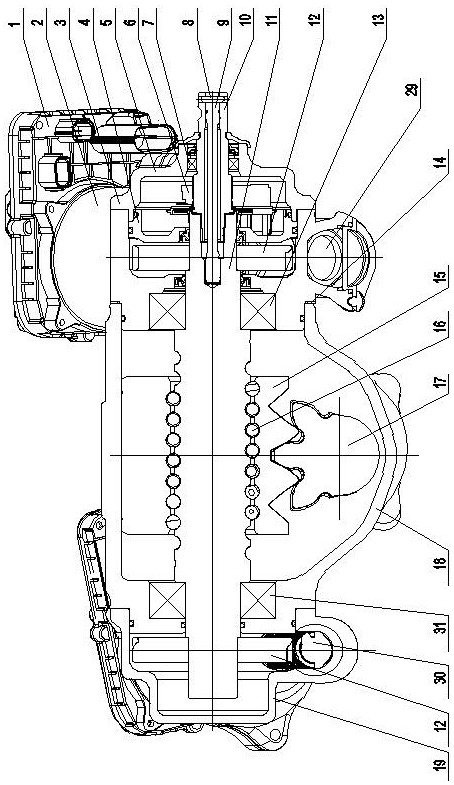

[0037] Such as figure 1 As shown, booster A and booster B are respectively arranged at both ends of the global steering gear;

[0038]First, the input shaft 10, the torsion bar 9, the steering screw 11, and the cylindrical pin 8 of the dual power-assisted mechanism of the recirculating ball steering gear are fixedly assembled into a steering screw assembly. The dual booster mechanism of the recirculating ball steering gear includes the recirculating ball steering gear body, booster A and booster B. The recirculating ball steering body includes an input shaft 10, a straight pin 8, a torsion bar 9, a bearing A13, an upper cover 5, an intermediate housing 3, a baffle plate 4, an adjusting gasket 14, a steering screw 11, a mechanical steering housing 18, Steering nut 15, steel ball 16, steering arm shaft and side cover assembly 17. The diverter housing 18 of the recirculating ball diverter body is provided with an assembly hole A29 and an assembly hole B30. The assembly hole A29...

Embodiment 2

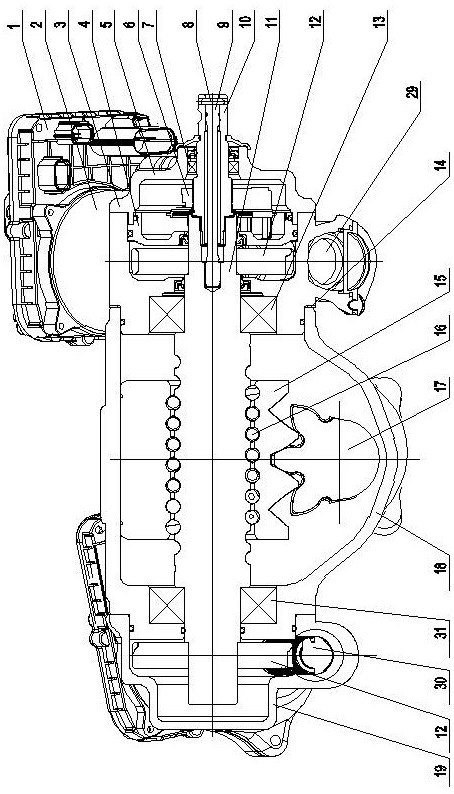

[0044] Such as figure 2 As shown, booster A and booster B are respectively arranged at the upper and lower parts of the tail end of the global steering gear;

[0045] First, the input shaft 10, the torsion bar 9, the steering screw 11, and the cylindrical pin 8 of the dual power-assisted mechanism of the recirculating ball steering gear are fixedly assembled into a steering screw assembly. The dual booster mechanism of the recirculating ball steering gear includes the recirculating ball steering gear body, booster A and booster B. The recirculating ball steering body includes an input shaft 10, a straight pin 8, a torsion bar 9, a bearing A13, an upper cover 5, an intermediate housing 3, a baffle plate 4, an adjusting gasket 14, a steering screw 11, a mechanical steering housing 18, Steering nut 15, steel ball 16, steering arm shaft and side cover assembly 17. The steering gear housing 18 of the recirculating ball steering gear body is provided with an assembly hole A29 and...

Embodiment 3

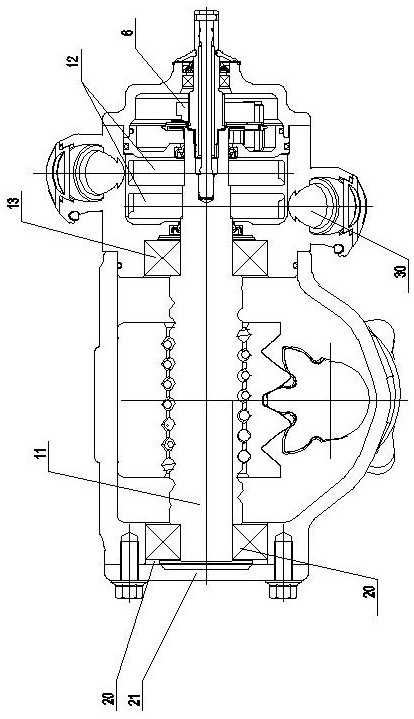

[0050] Such as image 3 As shown, booster A and booster B are respectively arranged at the upper and lower parts of the front end of the global steering gear;

[0051] First, the input shaft 10, the torsion bar 9, the steering screw 11, and the cylindrical pin 8 of the dual power-assisted mechanism of the recirculating ball steering gear are fixedly assembled into a steering screw assembly. The dual booster mechanism of the recirculating ball steering gear includes the recirculating ball steering gear body, booster A and booster B. The recirculating ball steering body includes an input shaft 10, a straight pin 8, a torsion bar 9, a bearing A13, an upper cover 5, an intermediate housing 3, a baffle plate 4, an adjusting gasket 14, a steering screw 11, a mechanical steering housing 18, Steering nut 15, steel ball 16, steering arm shaft and side cover assembly 17. The steering gear housing 18 of the recirculating ball steering gear body is provided with an assembly hole A29 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com