Folding structure for full-sea-condition long-voyage unmanned sailboat

A folding structure, long-range technology, applied in the field of sailboats, can solve the problems that appear at the connection between the beam rod and the canvas, the sail is not smooth enough to rise and fall, and it is inconvenient to control, so as to improve the strength of the sail body, move smoothly, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

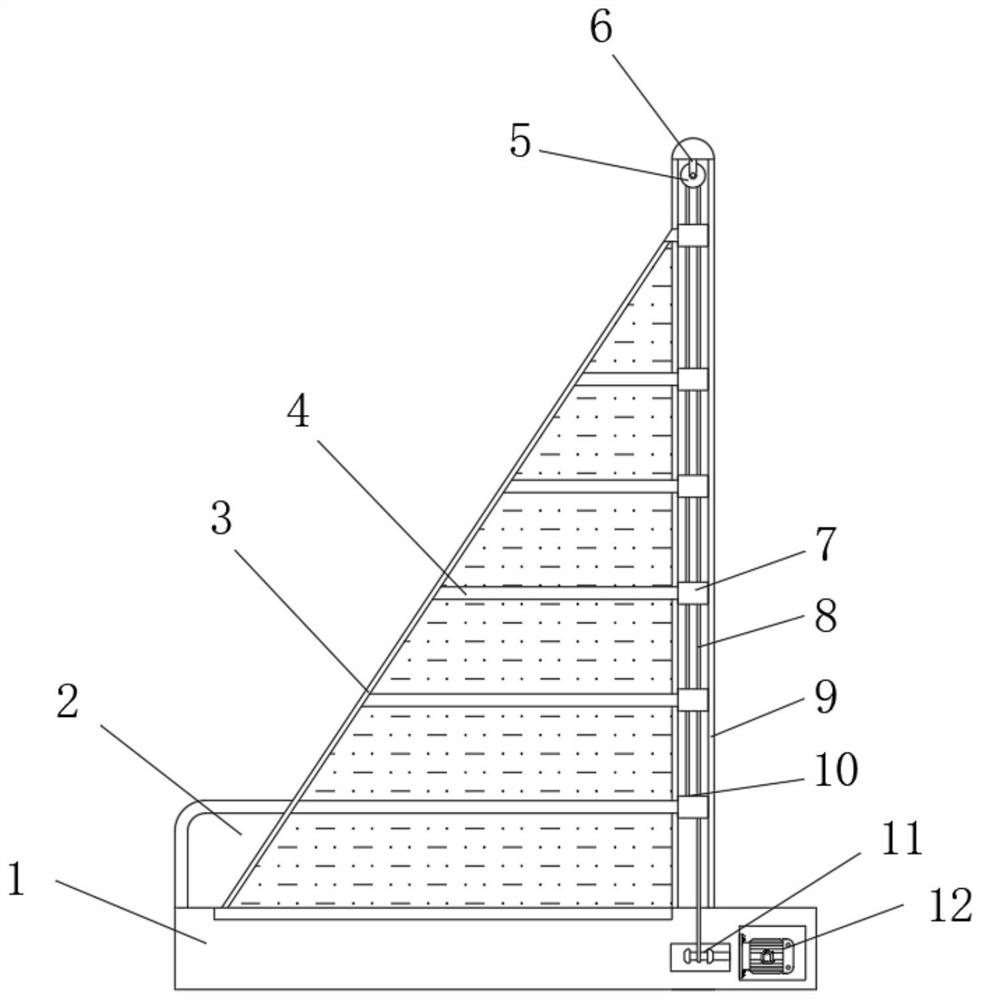

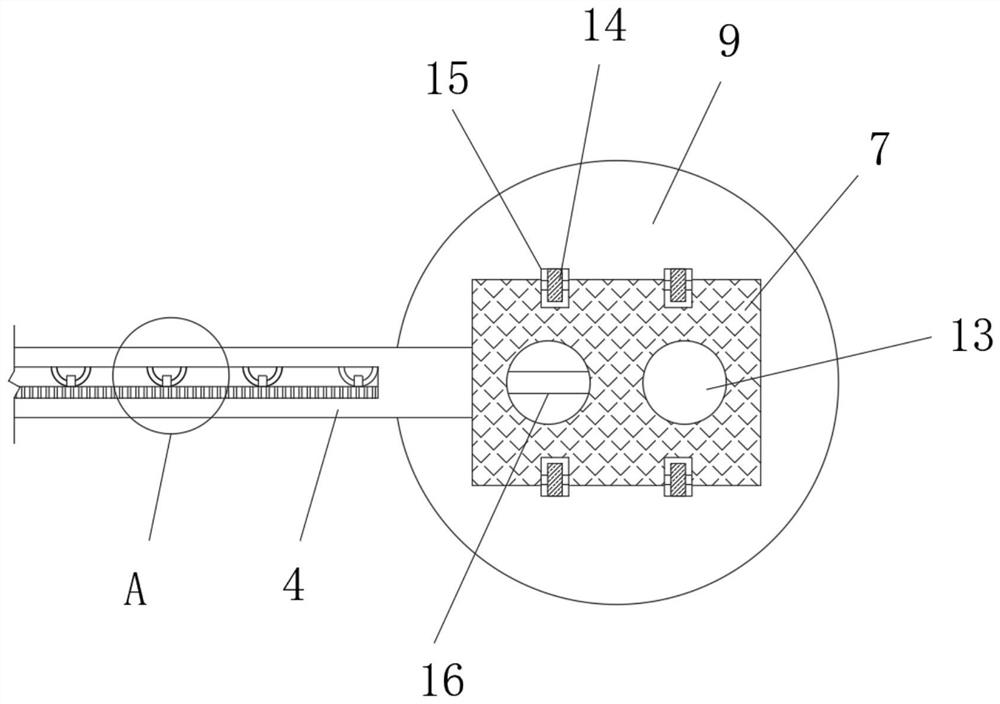

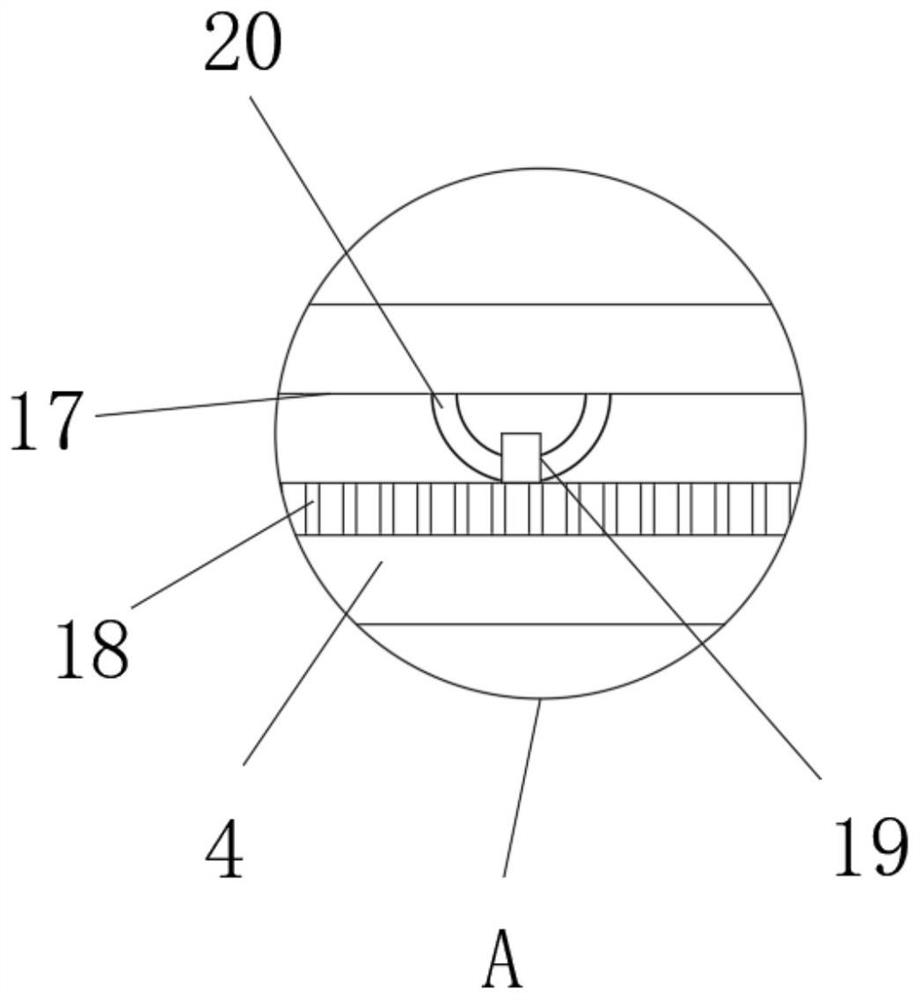

[0020] Example 1, such as figure 1 As shown, a folding structure for long-range unmanned sailboats in all sea conditions, including a base 1, a stand 9 is installed above one end of the base 1, the stand 9 adopts a hollow structure, and the stand 9 is internally installed with A plurality of lifting blocks 7, one end of each lifting block 7 is equipped with a beam bar 4, and a canvas 18 is installed on the beam bar 4, and all the beam bars 4 are away from one end of the lifting block 7 through a connecting belt 3 connection, the length of the beam bar 4 decreases successively from top to bottom; the lifting block 7 and the stand 9 are connected by sliding, and the two adjacent lifting blocks 7 are connected to each other, so A lifting mechanism for controlling the rise of the lifting block 7 is also installed in the stand 9.

[0021] Described lifting mechanism comprises traction rope 8, fixed pulley 5, reel 11 and first motor 12 and second motor, all is provided with a secon...

Embodiment 2

[0029] Embodiment 2: a specific structure of a folding structure for a long-range unmanned sailboat in all sea conditions, such as Figure 1-2 As shown, including the base 1, a stand 9 is installed above one end of the base 1, the stand 9 adopts a hollow structure, and a plurality of lifting blocks 7 are installed inside the stand 9, and a crossbeam bar 4 is installed at one end of each lifting block 7, Canvas 18 is installed on the beam bar 4 .

[0030] Adopt sliding connection between lifting block 7 and stand 9, connect mutually between two adjacent lifting blocks 7, also be installed in the stand 9 and be used to control the hoisting mechanism that lifting block 7 rises.

[0031] Hoisting mechanism comprises traction rope 8, fixed pulley 5, reel 11 and first motor 12 and second motor, wherein:

[0032] The reel 11 and the first motor 12 are all arranged in the base 1, the reel 11 is installed on the output shaft of the first motor 12, the fixed pulley 5 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com