Air locking unloader and control method

A technology of unloader and air lock, which is applied in the direction of program control, general control system, electrical program control, etc., can solve problems such as power tripping and stopping, so as to improve production efficiency, reduce adverse effects, and reduce both automatic and manual operations. The effect of power on and off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

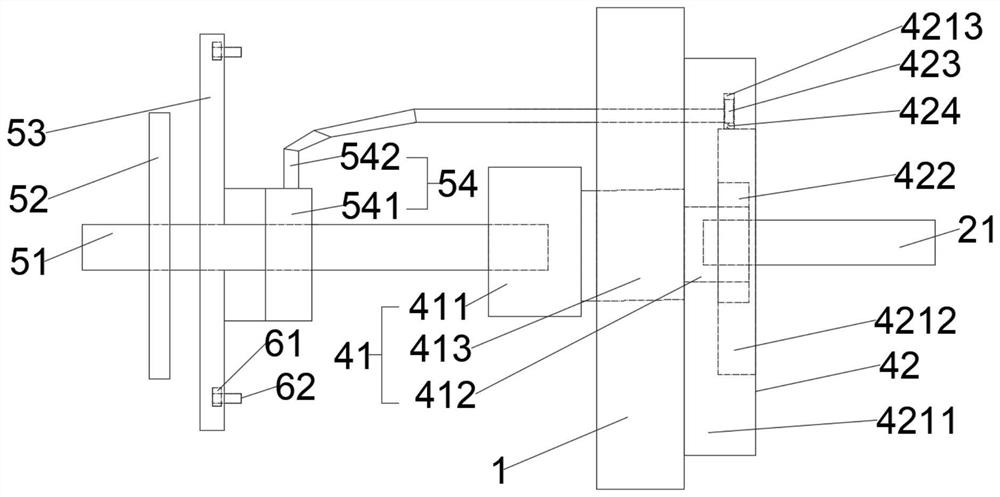

[0100] The sealing gasket disk 421 includes a sealing tray 4211, a groove 4212 and a movable cavity 4213 opening on the sealing disc 4211; the sealing disc body 4211 is fixed to the inner wall of the unloader body 1 and fixed to the second shaft sleeve 412 Connect, and the second shaft sleeve 412 is located in the end portion of the discharge body 1 through the sealing tray 4211 in the groove 4212;

[0101] The rolling shaft sleeve 422 is disposed in the groove 4212, and when the rolling shaft sleeve 422 is eccentric, the rolling shaft sleeve 422 is slidably sliding in the inner surface of the groove 4212 in the inner surface of the groove 4212 in the groove 4212 when the rotation shaft 21 is rotated. The position of the sleeve 422 varies with the angle of rotation shaft 21;

[0102] The active cavity 4213 is disposed in a radial direction in the sealing disc body 4211, and one end portion of the movable chamber 4213 is in communication with the groove 4212, one end of the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com