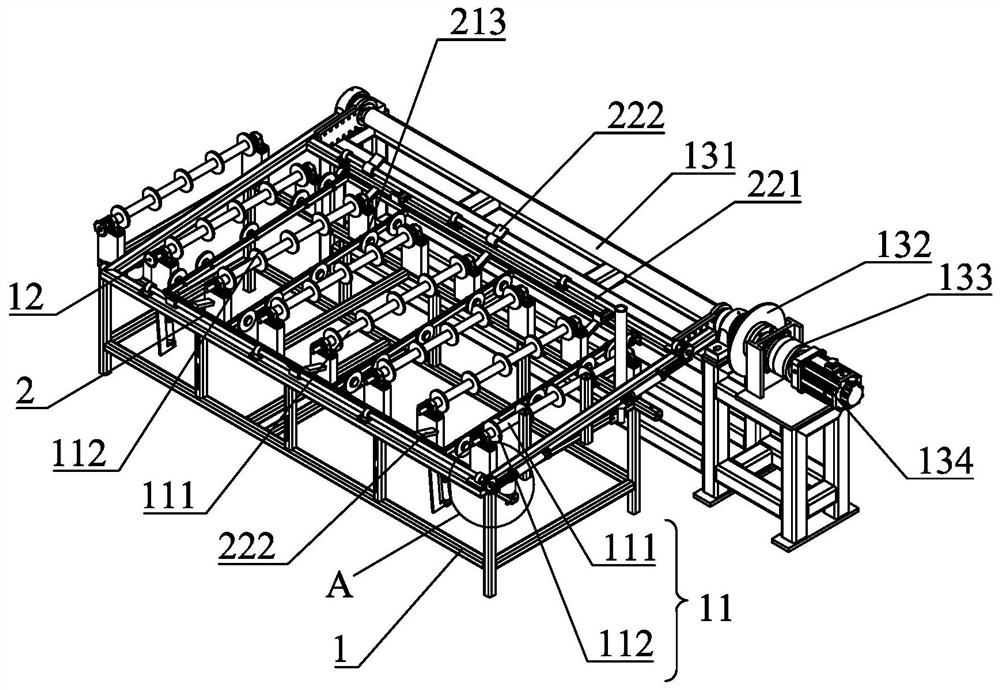

Veneering automatic turnover machine and working method thereof

An automatic flipping and veneering technology, applied in conveyors, manufacturing tools, conveyor objects, etc., can solve the problems of heavy workload, inconvenient handling by workers, restricting plate production efficiency, etc., so as to reduce workload and reduce falling off. Risk, achieve the effect of pressing and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

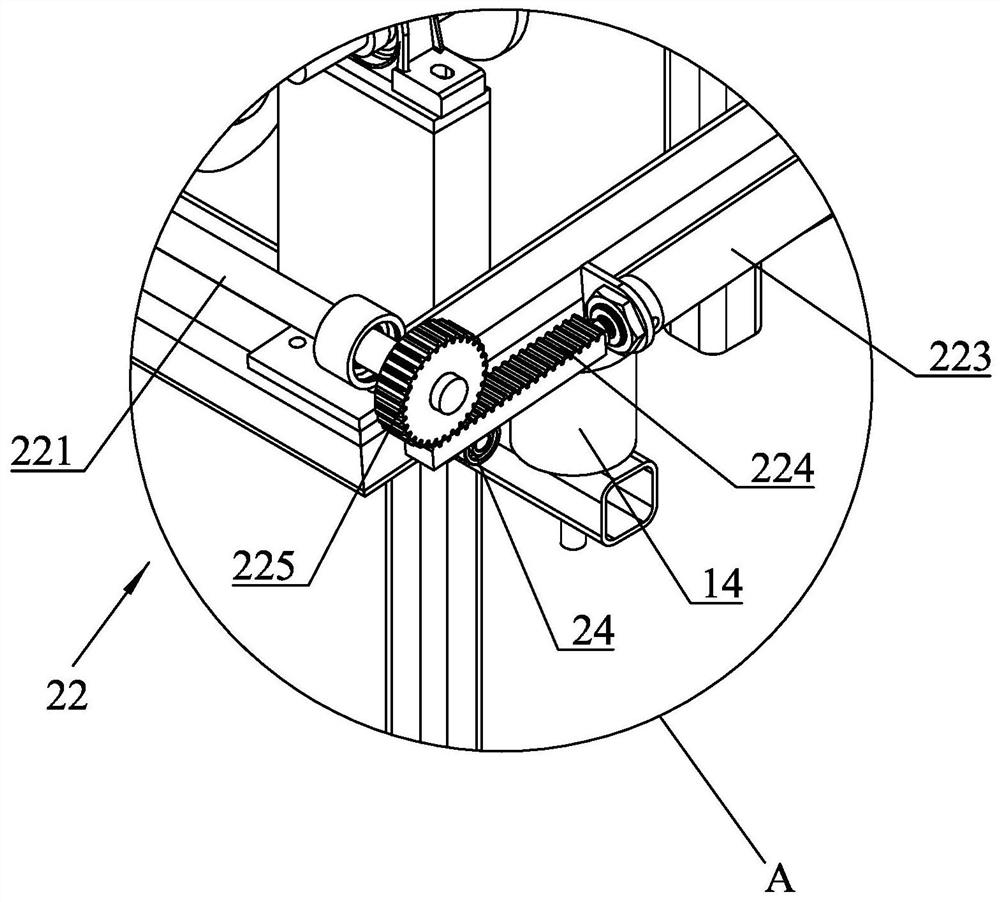

Method used

Image

Examples

Embodiment approach

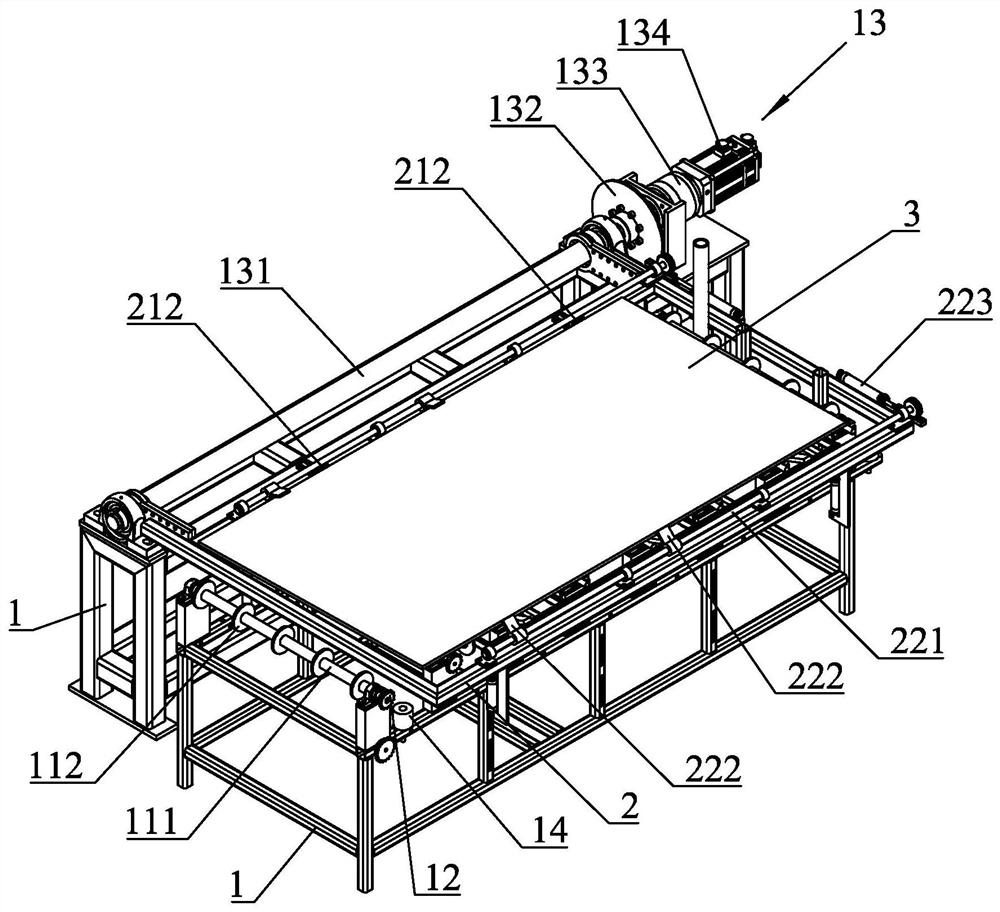

[0049] Preferably, as another embodiment of the overturn driving mechanism 13, the overturn driving mechanism 13 includes a rotating shaft 131, a gear plate 135, a driving motor 136 and a driving gear 137, and the rotating shaft 131 is rotatably connected to the base 1 and It is fixedly connected with the turning frame 2, the gear plate 135 is fixedly connected coaxially with the rotating shaft 131, the driving motor 136 is fixedly connected on the base 1, and the driving gear 137 is connected to the driving motor On the output shaft of 136, the driving gear 137 is meshed with the gear plate 135 and can drive the gear plate 135 to rotate. The driving motor 136 of the overturning driving structure drives the driving gear 137 to rotate, thereby driving the gear plate 135 to rotate, and the rotating shaft 131 rotates with the rotation of the gear plate 135, passing through the driving gear 137 and to the gear plate 135 The deceleration effect of the deceleration has played the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com