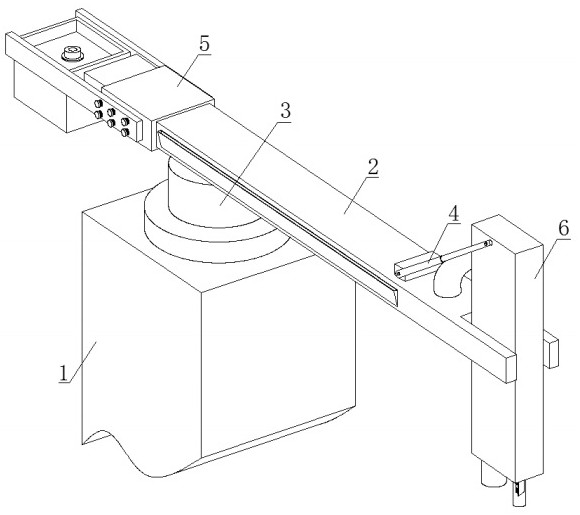

Screw ship unloader with scraper assembly for ships and its implementation method

A ship unloader and scraping technology, applied in conveyors, loading/unloading, conveyor objects, etc., can solve the problems of high functional consumption, waste, dust, etc., and achieve the effect of reducing work costs and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

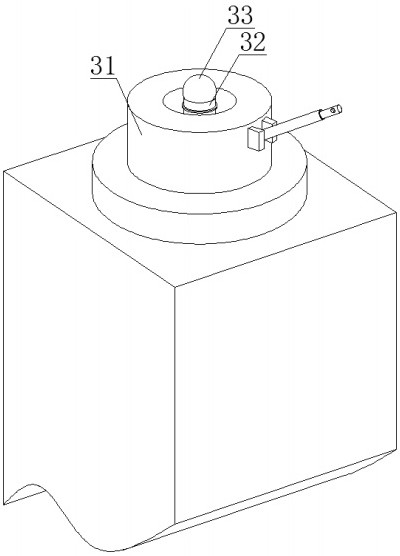

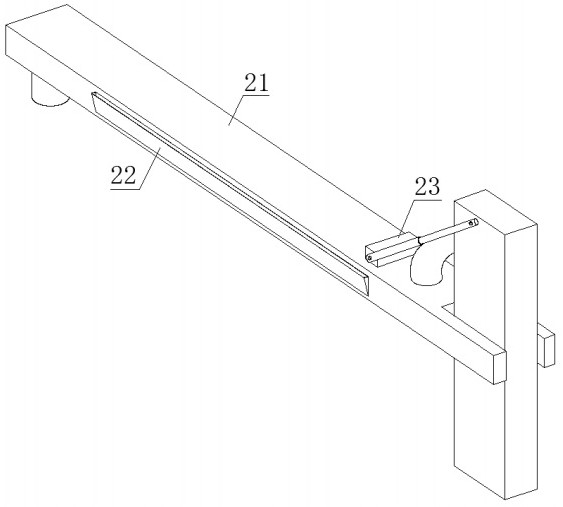

Embodiment approach , 1 Embodiment approach

[0043] In order to further and better explain the above embodiments, the present invention also provides an embodiment, a method for implementing a screw ship unloader with a scraper assembly for a ship, comprising the following steps:

[0044] Step 1: Align the unloading mechanism 6 with the place that needs to be unloaded on the ship, loosen the baffle plate 621 and the main connecting pipe 642, and the suction pipe 641 will drop due to gravity, and adjust it to a suitable height to be unloaded. Then the baffle plate 621 is fixed with the main connecting pipe 642;

[0045] Step 2: The generated negative pressure will transport the material from the suction pipe 641 to the inside of the guide pipe 271, and at the same time inject water into the external box 22, and the water will enter the soft side pipe 273, thereby forming a buffer and fixation for the guide pipe 271;

[0046] Step 3: Before the unloading is finished, use the movement of the slider 632 to drive the scraper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com