OH-HBP-containing high-strength coarse-denier polyvinyl alcohol fiber and preparation method thereof

A technology of OH-HBP, polyvinyl alcohol fiber, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problem of excessive viscosity of polyvinyl alcohol spinning solution, difficulty in spinning, Problems such as poor spinnability, to achieve the effect of increasing interaction, reducing tangles, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A preparation method of high-strength coarse denier polyvinyl alcohol fibers containing OH-HBP, the specific steps are as follows:

[0063] (1) prepare polyvinyl alcohol swelling liquid and OH-HBP respectively;

[0064] (1.a) preparing polyvinyl alcohol swelling liquid;

[0065] Polyvinyl alcohol with a degree of polymerization of 3100, a degree of alcoholysis of 98%, and an average fineness of 20 meshes is added to DMF and H at a mass ratio of 6:2. 2 After being in the mixed solution of O, heat up from 25°C to 40°C for 20min, and then continue to heat up to 50°C for 30min, to obtain a polyvinyl alcohol swelling solution with a polyvinyl alcohol content of 36wt%.

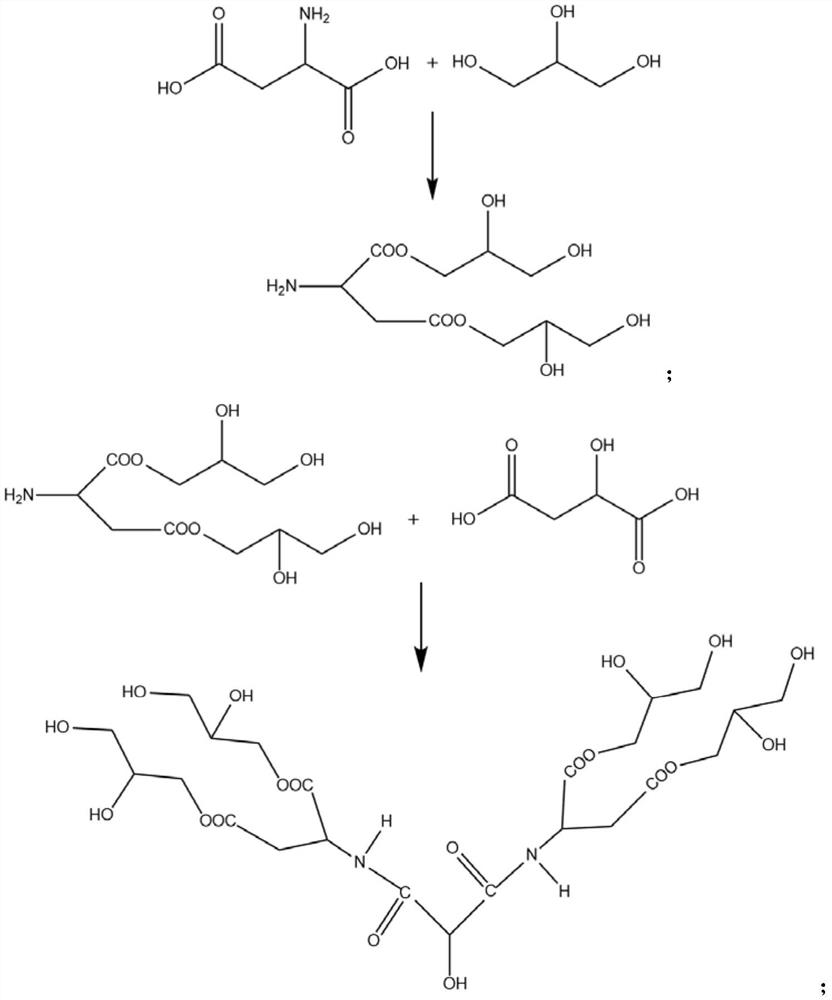

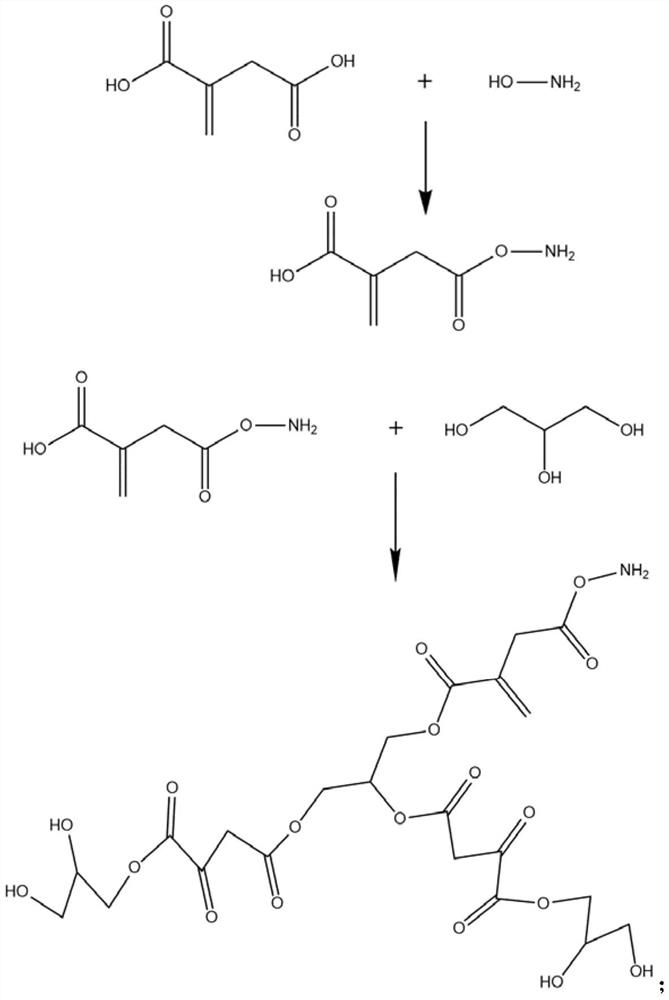

[0066] (1.b) preparing OH-HBP;

[0067] First, glutamic acid, glycerin, DMAc and catalyst z (the concentrated sulfuric acid of concentration 95wt%) are added in the reaction kettle to dissolve and react, obtain AB monomer after stirring 5h at 25 ℃, then add catalyst m (concentration 95wt% Concentrated sulf...

Embodiment 2

[0077] A preparation method of high-strength coarse denier polyvinyl alcohol fibers containing OH-HBP, the specific steps are as follows:

[0078] (1) prepare polyvinyl alcohol swelling liquid and OH-HBP respectively;

[0079] (1.a) preparing polyvinyl alcohol swelling liquid;

[0080] Polyvinyl alcohol with a degree of polymerization of 32000, a degree of alcoholysis of 98.2%, and an average fineness of 40 meshes is DMF and H at a mass ratio of 7:2.5 2 After being in the mixed solution of O, heat up from 26°C to 42°C for 18min, and then continue to heat up to 52°C for 28min, to obtain a polyvinyl alcohol swelling solution with a polyvinyl alcohol content of 38wt%.

[0081] (1.b) preparing OH-HBP;

[0082] First, glutamic acid, glycerol, DMAc and catalyst z (concentration of 96wt% concentrated sulfuric acid) were added to the reactor to dissolve and react, and after stirring for 4.5h at 30°C, AB monomer was obtained, and then catalyst m (concentration of 96wt%) was added co...

Embodiment 3

[0092] A preparation method of high-strength coarse denier polyvinyl alcohol fibers containing OH-HBP, the specific steps are as follows:

[0093] (1) prepare polyvinyl alcohol swelling liquid and OH-HBP respectively;

[0094] (1.a) preparing polyvinyl alcohol swelling liquid;

[0095] Polyvinyl alcohol with a degree of polymerization of 33000, a degree of alcoholysis of 98.4%, and an average fineness of 60 meshes was added to DMF and H with a mass ratio of 8:3. 2 After being in the mixed solution of O, heat up from 27°C to 44°C for 16 minutes, and then continue to heat up to 54°C for 26 minutes to obtain a polyvinyl alcohol swelling solution with a polyvinyl alcohol content of 39 wt%.

[0096] (1.b) preparing OH-HBP;

[0097] First, glutamic acid, glycerin, DMAc and catalyst z (the concentrated sulfuric acid of concentration 98wt%) are added in the reaction kettle to dissolve and react, obtain AB monomer after stirring 4h at 35 ℃, then add catalyst m (concentration 98wt% Con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap