Large tank metal heat preservation structure

A metal and tank technology, applied in the field of metal insulation structure of large tanks, can solve the problems of large dust and short life, and achieve the effects of prolonging service life, avoiding continuous maintenance, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

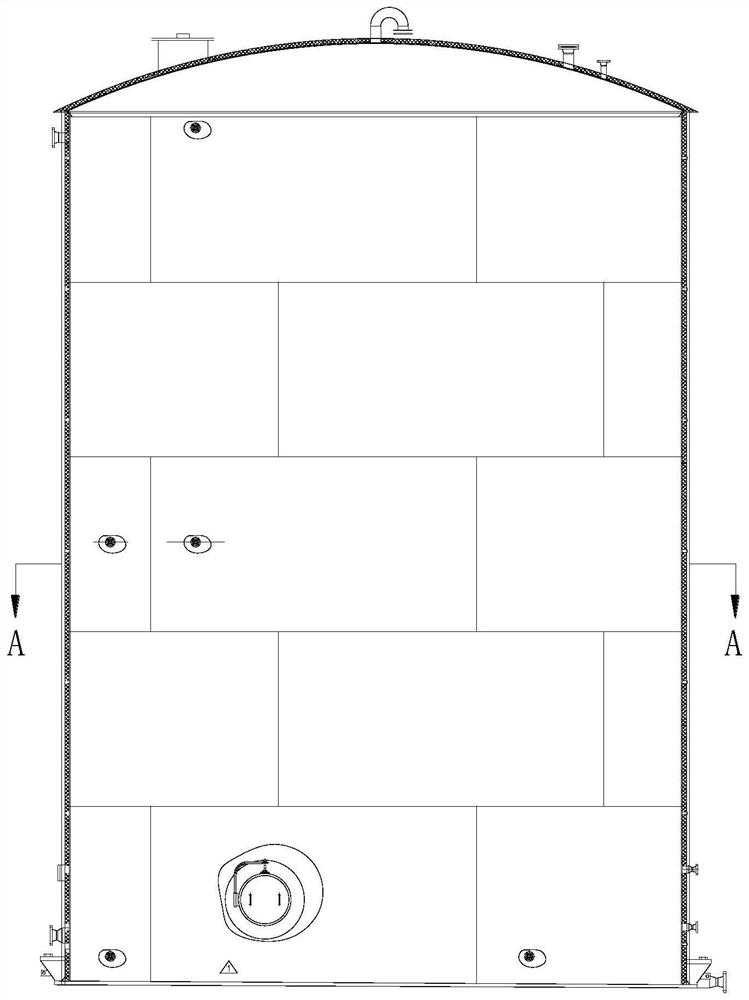

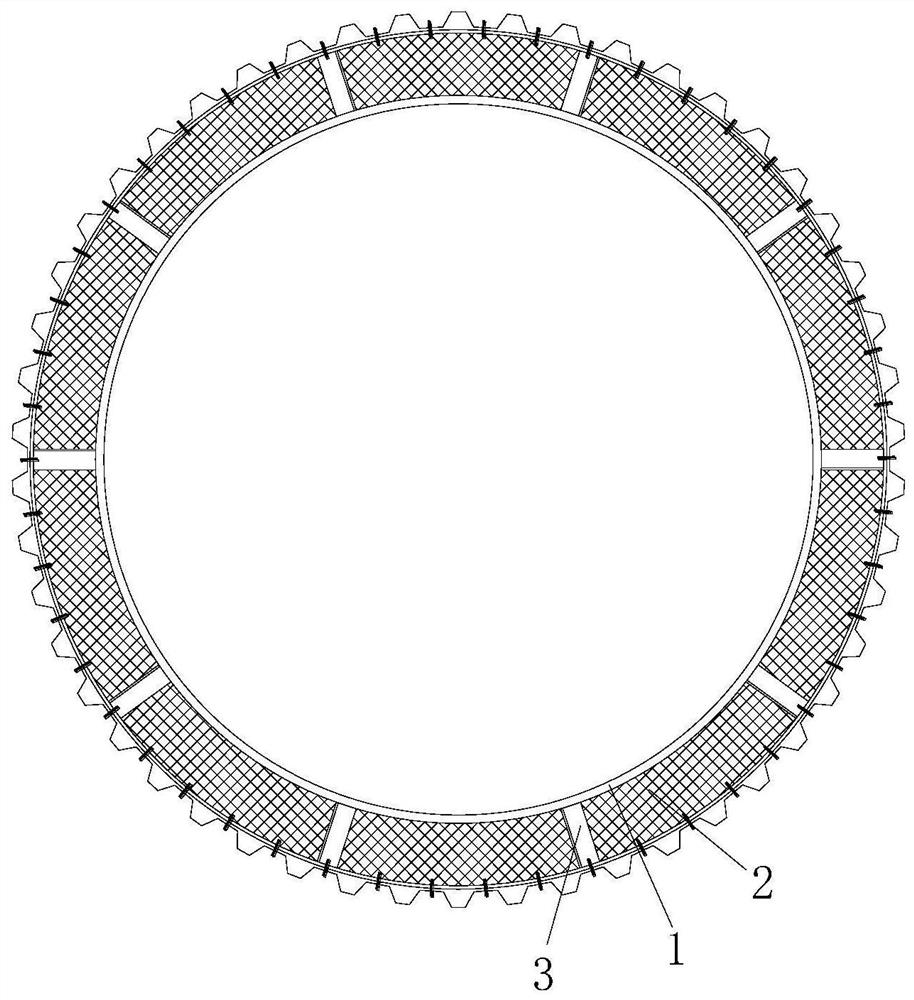

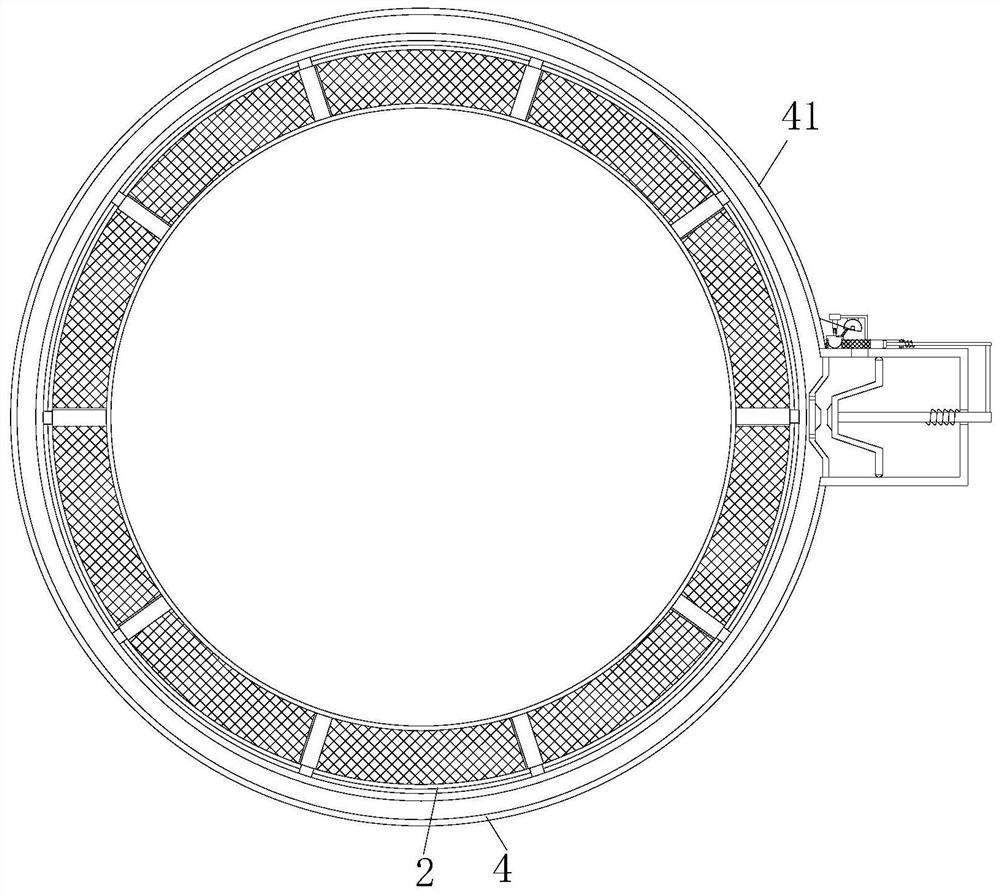

[0032] Attached below Figure 1-7 The present invention is further described with embodiment:

[0033] A large-scale tank metal insulation structure, including a tank body 1 and an angle steel bracket 3, a number of angle steel brackets 3 are fixedly inserted on the tank body 1, a metal insulation foil 2 is arranged outside the tank body 1, and the angle steel bracket 3 is plugged and arranged on On the metal insulation foil 2, after improving the insulation structure outside the existing pressure vessel in the present invention, the improved insulation layer uses metal materials to replace the existing non-metallic materials, so that in the process of use, both the heat preservation can be extended The service life of the layer can be improved. At the same time, when replacing, it can achieve convenient replacement and avoid the problem of dust generation. Therefore, the improved insulation layer has a higher use value.

[0034]In this embodiment, the metal insulation foil 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com