Method and system for modifying fuel gas nozzle based on fuel oil nozzle

A technology of gas nozzles and fuel nozzles, which is applied in the direction of combustion methods, combustion chambers, combustion equipment, etc., and can solve the problem that gas fuel cannot be effectively injected into the combustion area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for modifying a gas nozzle based on a fuel nozzle, comprising the steps of:

[0039] Step 1) Select a certain working condition as the design point of the gas nozzle, obtain the pressure drop of the gas nozzle, and calculate the gas injection velocity;

[0040] Step 2) based on the size of the fuel nozzle and the gas injection velocity, obtain the total area of the nozzles on the gas nozzle, and calculate the number and diameter of the nozzles;

[0041] The process of obtaining the total area of the nozzle is:

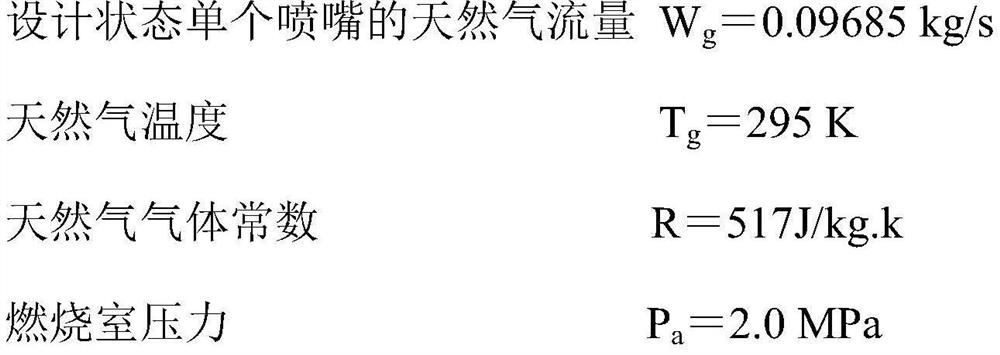

[0042] Calculate the gas density based on the gas temperature, gas constant and combustion chamber pressure;

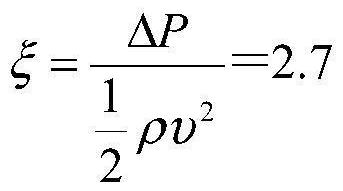

[0043] According to the gas density, nozzle form and wall thickness, the flow resistance coefficient of the nozzle is obtained;

[0044] Based on the pressure drop of the gas nozzle, the gas injection velocity and the flow resistance coefficient of the nozzle, the total area of the nozzle is calculated.

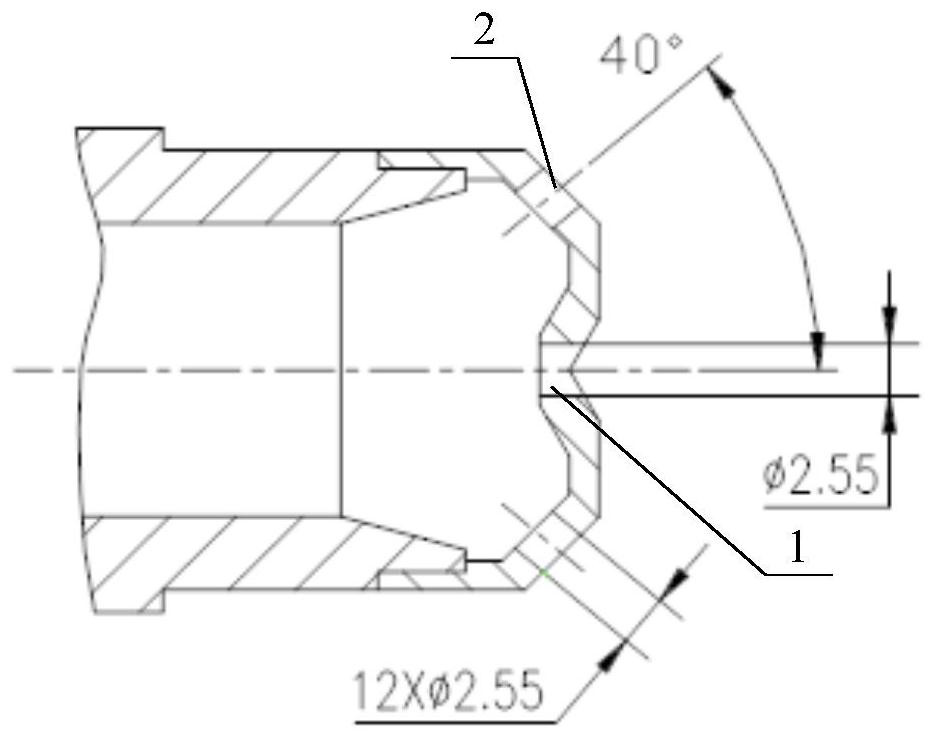

[0045] Step 3) Obtain the layo...

Embodiment 2

[0049] Except for the following content, all the other contents are the same as in Example 1.

[0050] The calculation process of the gas injection velocity is as follows: the gas flow rate is obtained based on the pressure drop of the gas nozzle, and the gas injection velocity is obtained by combining the gas temperature, the gas constant of the gas and the pressure of the combustion chamber.

[0051] The calculation process of the number and diameter of the nozzles is: based on the total area of the nozzles and the nozzle diameter of the fuel nozzle, the area and the number of the individual nozzles are calculated; based on the number of the nozzles and the area of the individual nozzles, the diameter of the individual nozzles is calculated.

Embodiment 3

[0053] A method for modifying a gas nozzle based on a fuel nozzle, comprising the steps of:

[0054] Step 1): For the design of the gas nozzle, the 1.0 working condition is selected as the nozzle design point. The design should ensure that the heat release per unit time when using natural gas is the same as when using diesel; ensure that the number of nozzles and installation dimensions remain unchanged.

[0055] According to the design data and actual use experience of the gas nozzle, the important design parameter is the nozzle pressure drop. The recommended nozzle pressure drop is about 10% of the gas supply pressure to ensure stable and efficient combustion and meet the requirements of outlet temperature distribution. At the same time, consider service life. If the pressure drop is too high, it will easily lead to unstable operation of the nozzle, and it is easy to spray to the near wall, resulting in excessive wall temperature; if the pressure drop is too low, the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com