Production equipment and production process of high-temperature-resistant anti-aging fixing adhesive tape for automobile

A kind of production equipment and anti-aging technology, which can be used in the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problems of poor coating operation, lack of integration, and troublesome production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

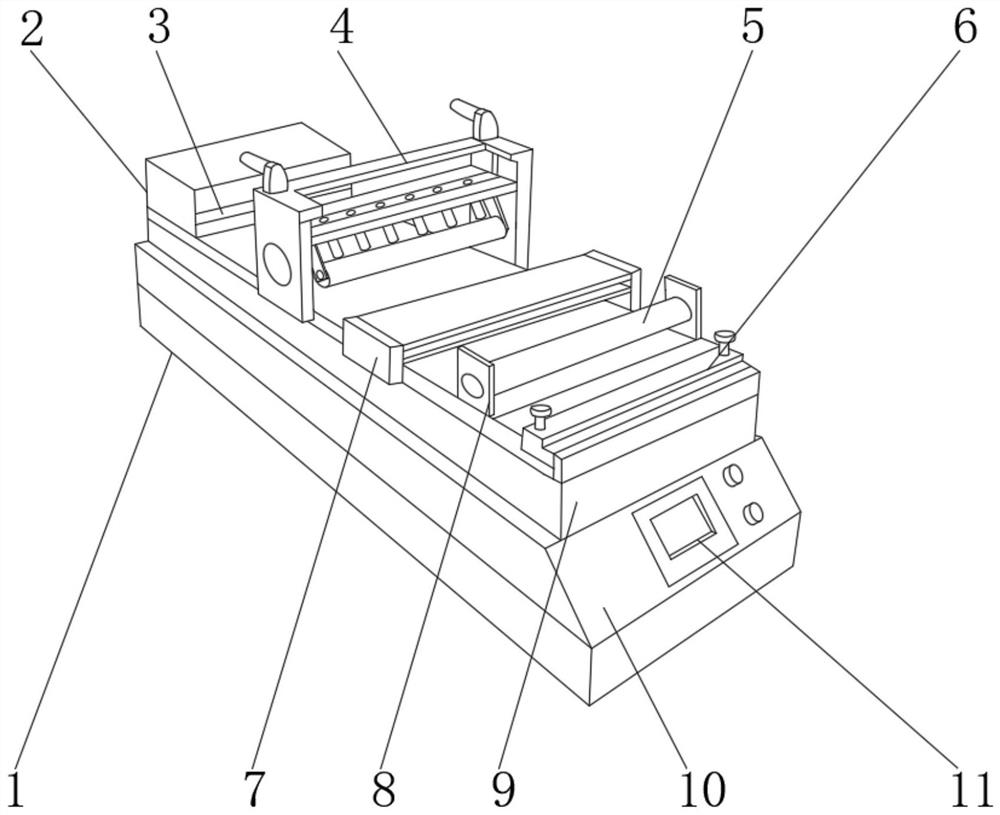

[0034] Such as Figure 1-3 As shown, a production equipment for high temperature and anti-aging anti-aging fixing tapes for automobiles comprises a tape base 1, a control box 10 is installed on the front end of the tape base 1, a display panel 11 is installed on the front end of the control box 10, and a display panel 11 is installed on the upper end of the tape base 1. There is a conveying seat 9, and the upper end of the conveying seat 9 is equipped with a film blowing machine 2, a convenient feeding type coating mechanism 4, a detachable drying mechanism 7, a positioning mounting seat 8 and a positioning mechanism 6, and the middle part of the film blowing machine 2 is set There is a material outlet 3, and the inside of the positioning mounting seat 8 is provided with a coiling mechanism 5.

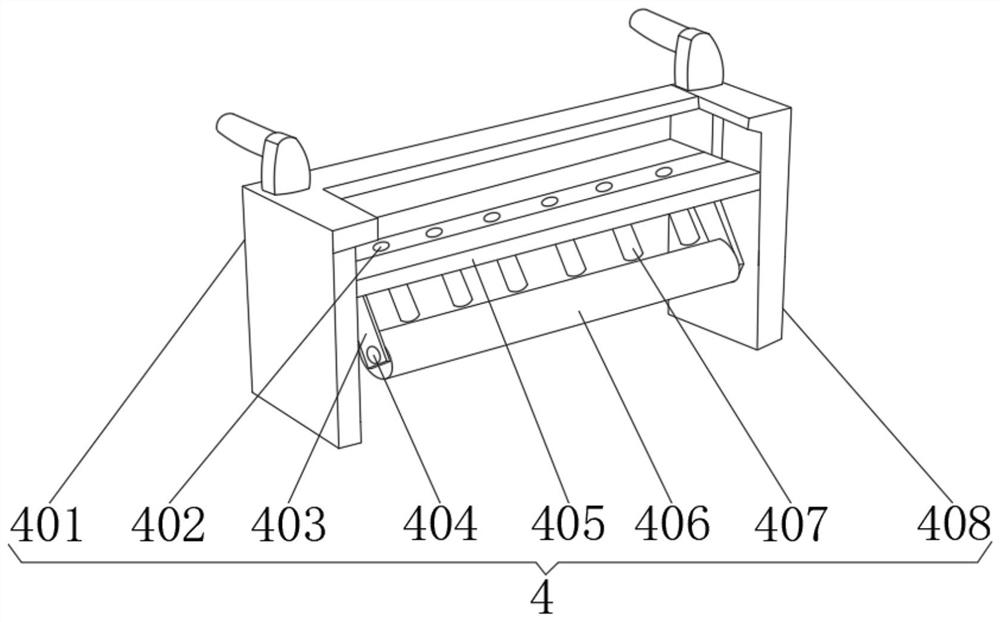

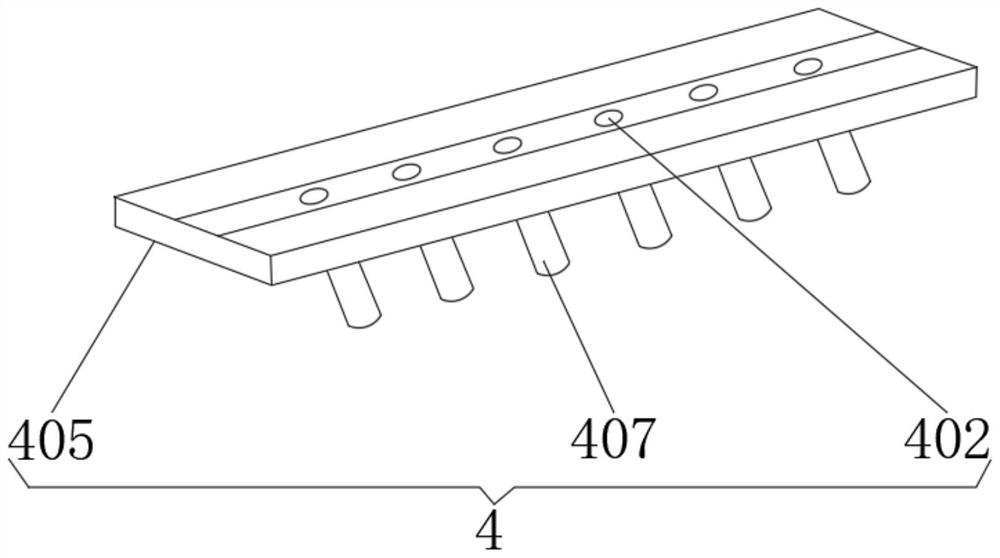

[0035] The feeding type coating mechanism 4 includes a No. 1 installation frame 401, a feed inlet 402, an adjustment frame 403, a movable shaft 404, an installation card frame 405, a c...

Embodiment 2

[0043] On the basis of Example 1, as figure 1 , 4 , shown in 5, a kind of production equipment of high temperature and anti-aging anti-aging fixed adhesive tape for automobiles, comprises adhesive tape base 1, and the front end of adhesive tape base 1 is equipped with control box 10, and the front end of control box 10 is equipped with display panel 11, and the front end of adhesive tape base 1 is equipped with The upper end is equipped with a conveying seat 9, and the upper end of the conveying seat 9 is equipped with a film blowing machine 2, a feeding type coating mechanism 4, a detachable drying mechanism 7, a positioning mounting seat 8 and a positioning mechanism 6, and the film blowing machine 2 The middle part is provided with a material outlet 3, and the inner side of the positioning mounting seat 8 is provided with a coiling mechanism 5.

[0044] The detachable drying mechanism 7 includes No. 1 positioning support 701, fan seat 702, drying seat 703, fan 704, No. 2 p...

Embodiment 3

[0054] On the basis of Example 2, such as figure 1 , 6 As shown, a production equipment for high temperature and anti-aging anti-aging fixing tapes for automobiles comprises a tape base 1, a control box 10 is installed on the front end of the tape base 1, a display panel 11 is installed on the front end of the control box 10, and a display panel 11 is installed on the upper end of the tape base 1. There is a conveying seat 9, and the upper end of the conveying seat 9 is equipped with a film blowing machine 2, a convenient feeding type coating mechanism 4, a detachable drying mechanism 7, a positioning mounting seat 8 and a positioning mechanism 6, and the middle part of the film blowing machine 2 is set There is a material outlet 3, and the inside of the positioning mounting seat 8 is provided with a coiling mechanism 5.

[0055] The control box 10 includes a temperature monitoring module, a power module, a PLC management module, a display module, a fan control module, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com