Patents

Literature

106results about How to "Easy drying operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

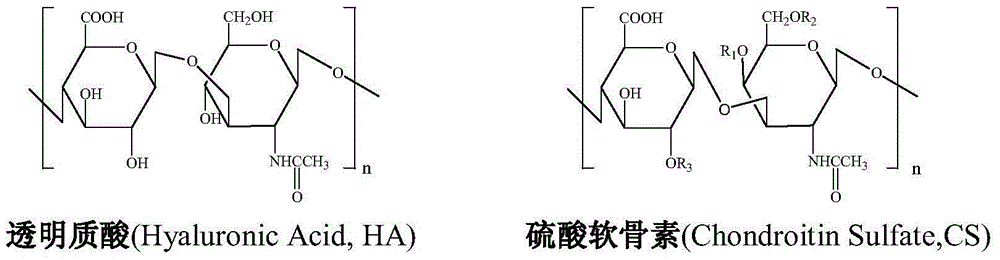

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

ActiveCN104531817ARealize simultaneous hydrolysisEmission reductionConnective tissue peptidesCutting soapResource utilizationHydrolysate

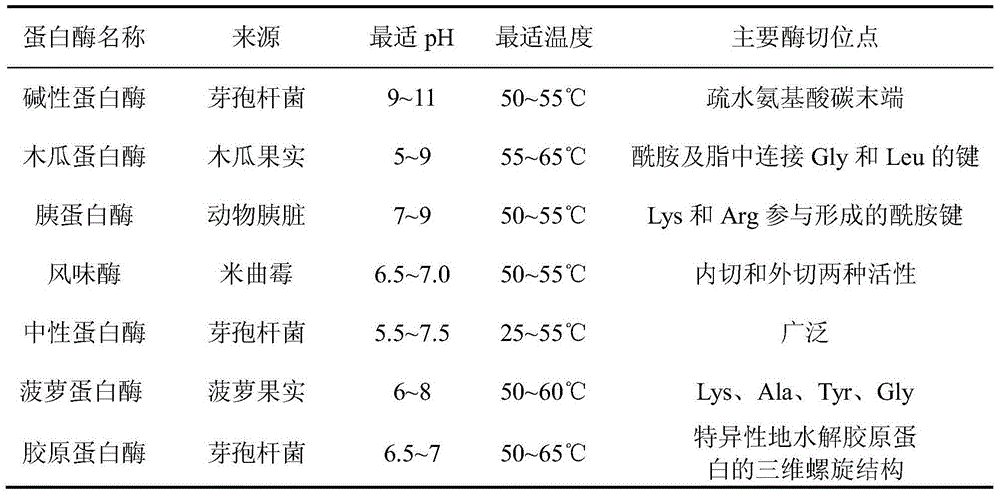

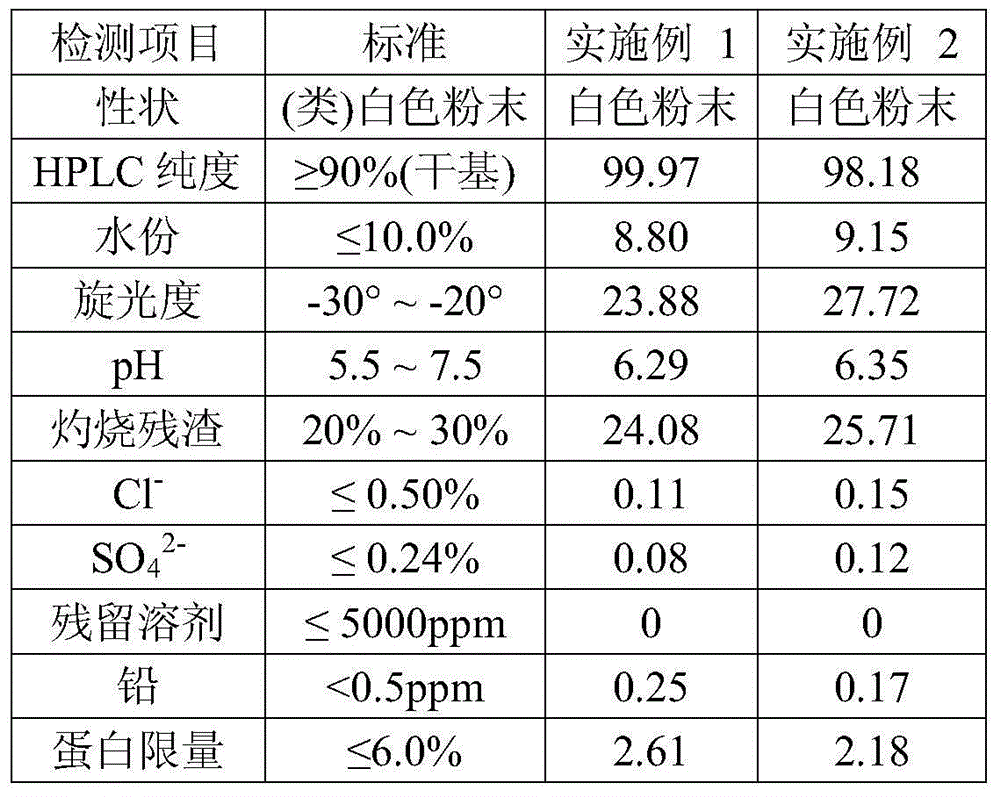

The invention discloses a combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap. The method mainly comprises the process steps that animal cartilage is soaked with water and smashed to obtain cartilage powder, the cartilage powder undergoes protease enzymolysis and then is adsorbed by resin, adsorbed enzymatic hydrolysate is collected, the resin undergoes gradient elution through a NaCl aqueous solution, and eluants undergo desalination, concentration, sterilization and drying to obtain finished products of the hyaluronic acid and chondroitin sulfate; the adsorbed enzymatic hydrolysate undergoes decoloration, anion and cation exchange resin mixed column treatment, nanofiltration purification, concentration, sterilization and drying to manufacture finished products of the collagen peptide; grease undergoes extraction saponification to manufacture the soap; denatured protein-bone dreg compounds and other materials are mixed to manufacture the fodder. According to the combined production method, by utilizing the process of resin adsorption-spray drying, highly-intensified resource utilization of cartilage is achieved, energy saving and emission reduction are achieved, and the economic benefit and the social benefit are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

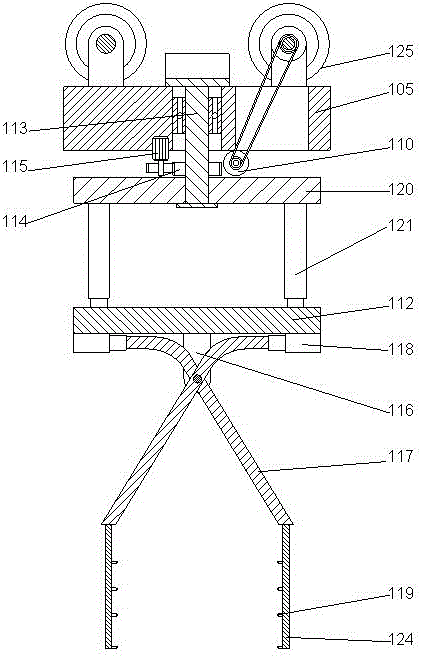

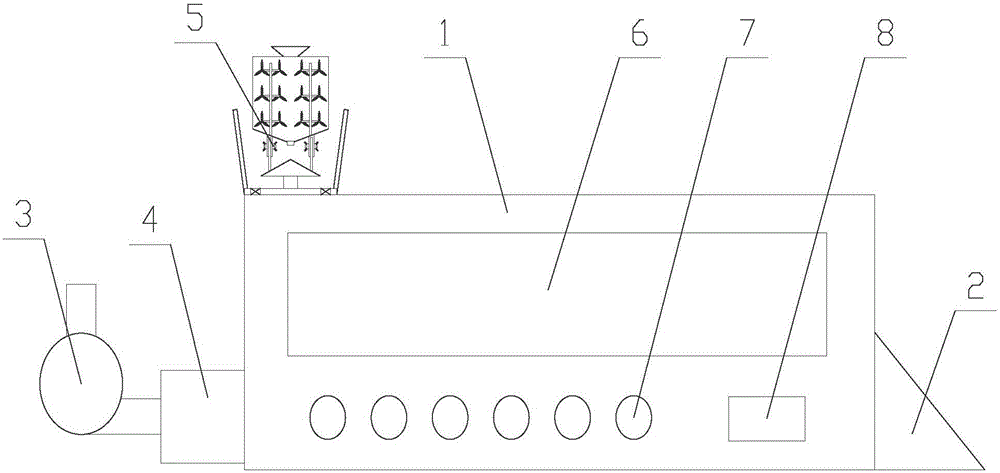

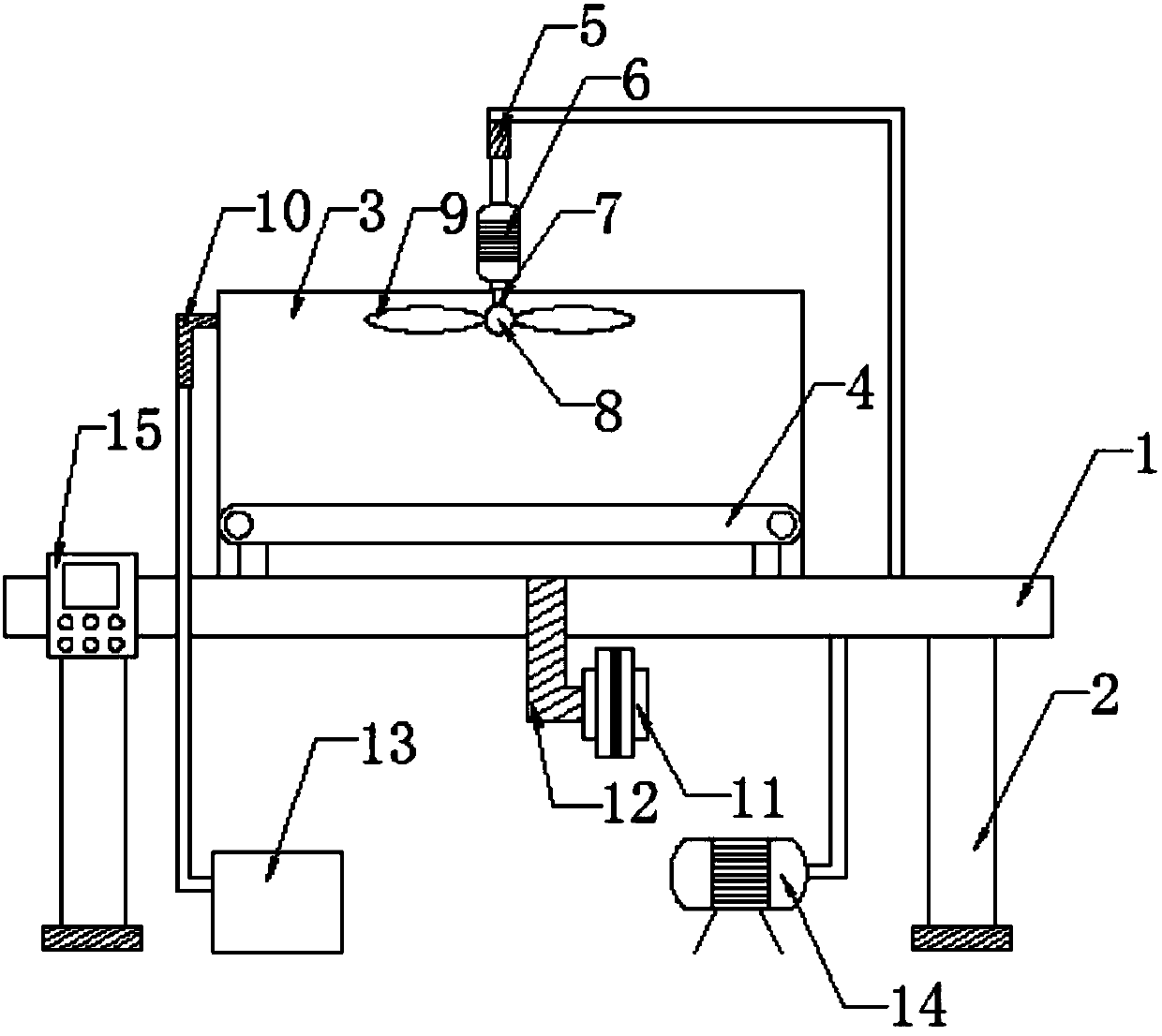

Integrated environment-friendly painting equipment

ActiveCN106269410APrevent sprayingAvoid wastingLiquid surface applicatorsCoatingsClamp connectionGear wheel

The invention discloses integrated environment-friendly painting equipment, comprising a hollow barrel-shaped paint box and two moveable tracks arranged above the paint box, wherein an air drying box is arranged at one side of the paint box, and at least two high-speed wind spray nozzles are arranged at the inner side of the air drying box; the moveable tracks are in an I shape; a mobile platform is arranged under the moveable tracks, two groups of gears are arranged above the mobile platform, and a drive motor is arranged under the mobile platform; the drive motor is used for driving the gears to rotate; two locating rods are arranged under the mobile platform; the end, far away from the mobile platform, of each locating rod is provided a roller wheel; the roller wheels are respectively in clamping connection with grooves formed in the two sides of the I shape formed by the moveable tracks and can roll along the length direction of the grooves. The integrated environment-friendly painting equipment can convey a material into a box body of the paint box, and enable excess paint on the surface of the material to fall off after dip-coating of the paint is completed, thus avoiding paint waste.

Owner:徐州利成环保材料有限公司

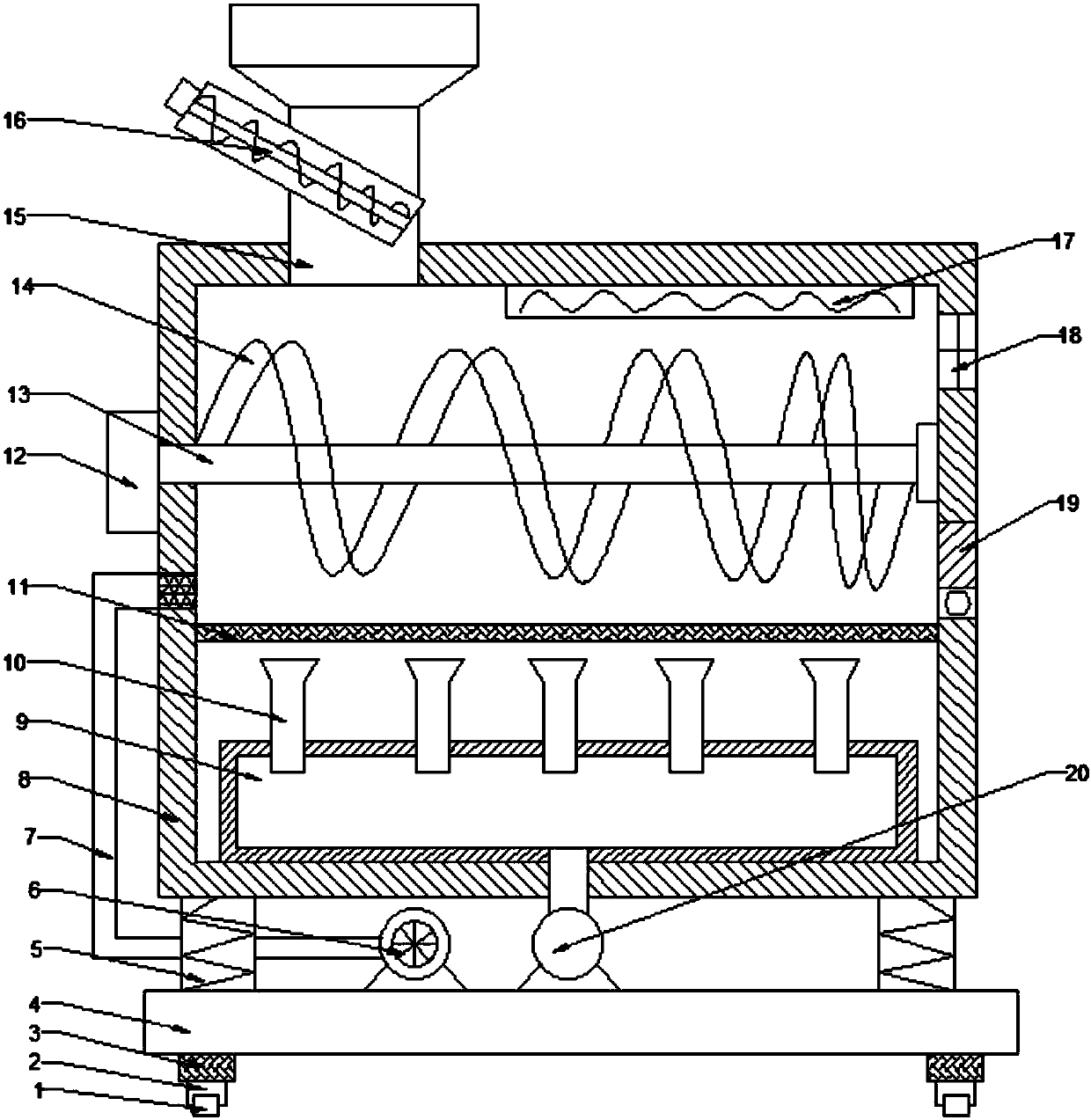

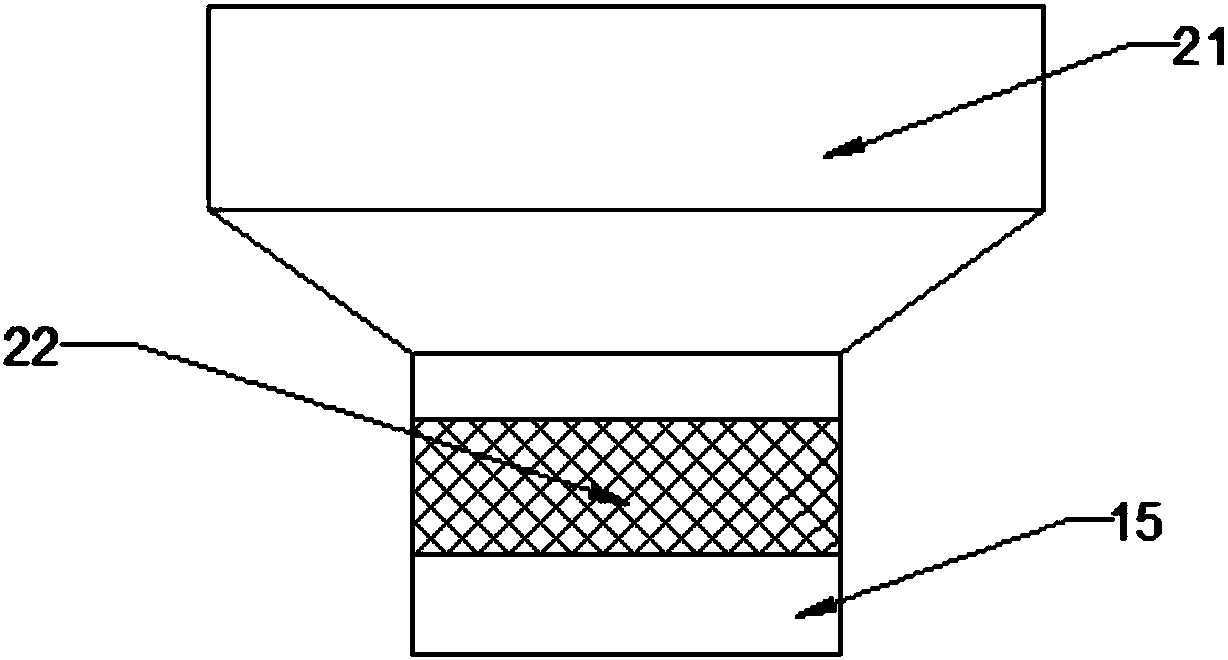

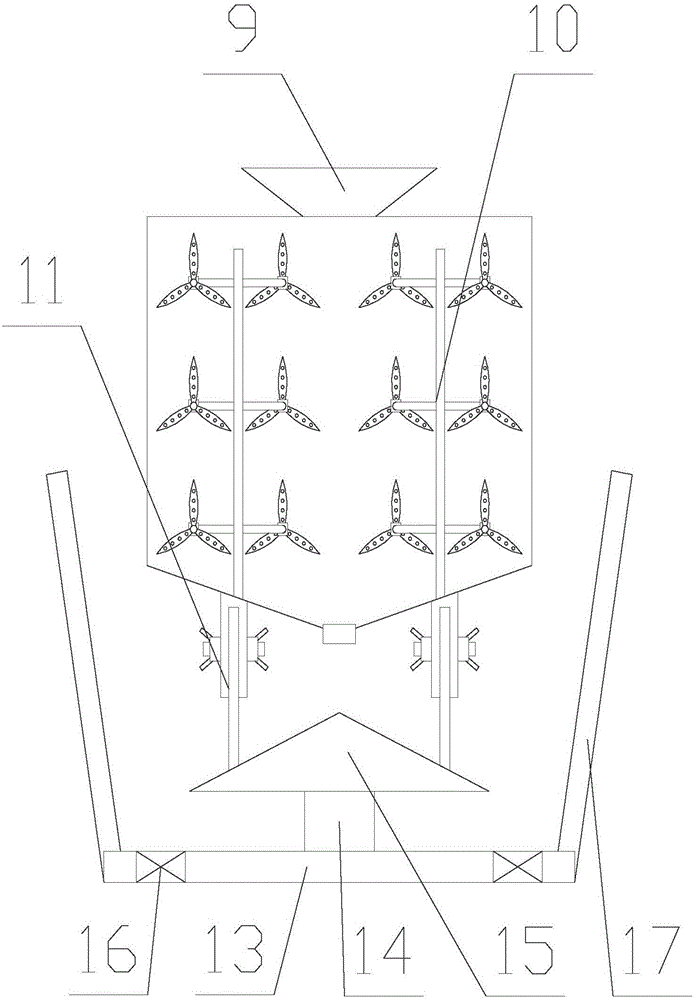

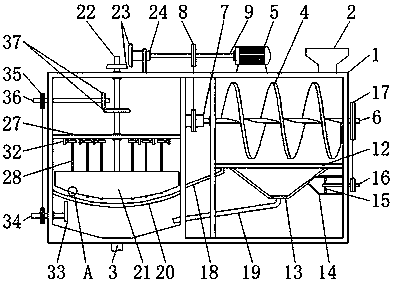

Drying and impurity-removing device for agricultural cereals

InactiveCN108036611AEasy dryingEasy to dryGas current separationDrying gas arrangementsSpiral bladeAgricultural engineering

The invention provides a drying and impurity-removing device for agricultural cereals and belongs to the agricultural field. The drying and impurity-removing device for agricultural cereals comprisesa moving device and a drying and impurity-removing device, wherein a feeding connector is obliquely arranged in a feeding hopper; an ultraviolet sterilizer is fixedly arranged on the right side of theupper end of an inner cavity of a box body; a filter screen is fixedly arranged on the lower side of the inner cavity of the box body; a plurality of dust collection pipes arranged at the lower end of the box body are arranged on the upper surface of a dust collecting box, and the nozzle of each dust collecting pipe is horn-shaped; a hot-air blower is welded and fixed to the left side of a bottomplate; and a discharging cover plate is hinged to the right side of the box body. By welding and fixing spiral blades on the rotary shaft, the device has the functions of overturning cereals to be dried conveniently and conveying the cereals rightward; the left end of the hot-air blower communicates to the left side of the box body through an air outlet pipe, so that the device has the functionsof blowing hot air to dry the cereals and blowing the cereals out conveniently. The device has the characteristics of being simple in structure, high in practicality and good in drying effect.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

Novel process for production of fragrant rice processing

InactiveCN106901154AGood for drying and ventilationEasy drying operationSeed preservation by dryingGrain millingNitrogenNitrogen gas

The invention relates to the technical field of rice processing, in particular to a novel process for production of fragrant rice processing. The novel process comprises the following steps, to be specific, (1) rice drying treatment; (2) rice impurity cleaning; (3) spray wetting; (4) rice milling for the first time; (5) drying once more; (6) rice milling for the second time; (7) polishing and blending rice; (8) fragrant rice weighing and packing. Through the above process, the fragrant rice quality has been effectively improved; meanwhile, the drying operation of fragrant rice processing is more convenient and more simple; the quality and safety of the novel process for production of rice processing are increased through the treatment of late sterilization and nitrogen packing and is favorable for long-term preservation; as different ratio and different levels of fragrant rice are mixed, the needs on different tastes of users are meet.

Owner:宁夏红阳合粮油有限公司

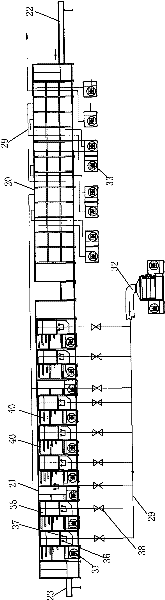

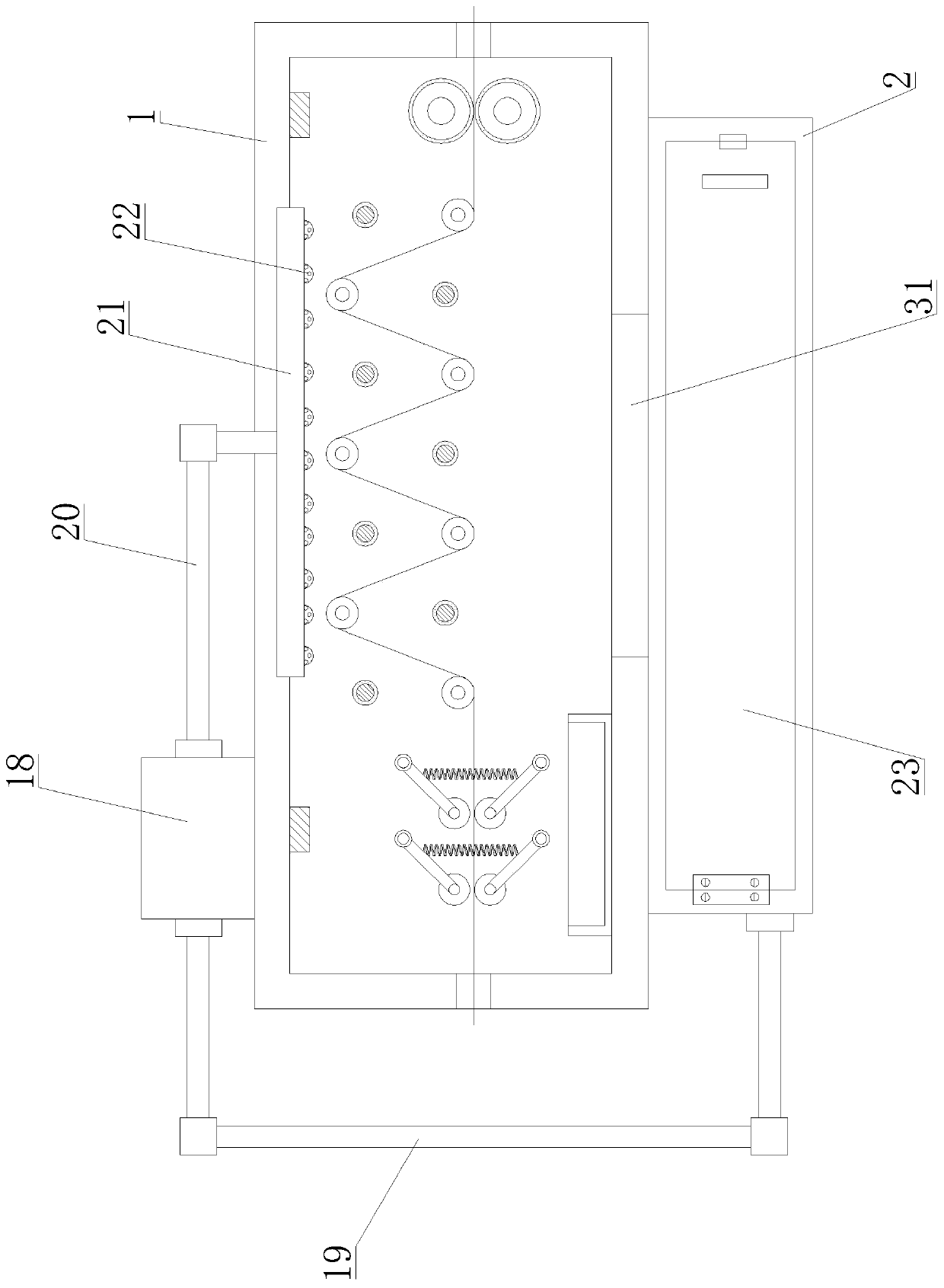

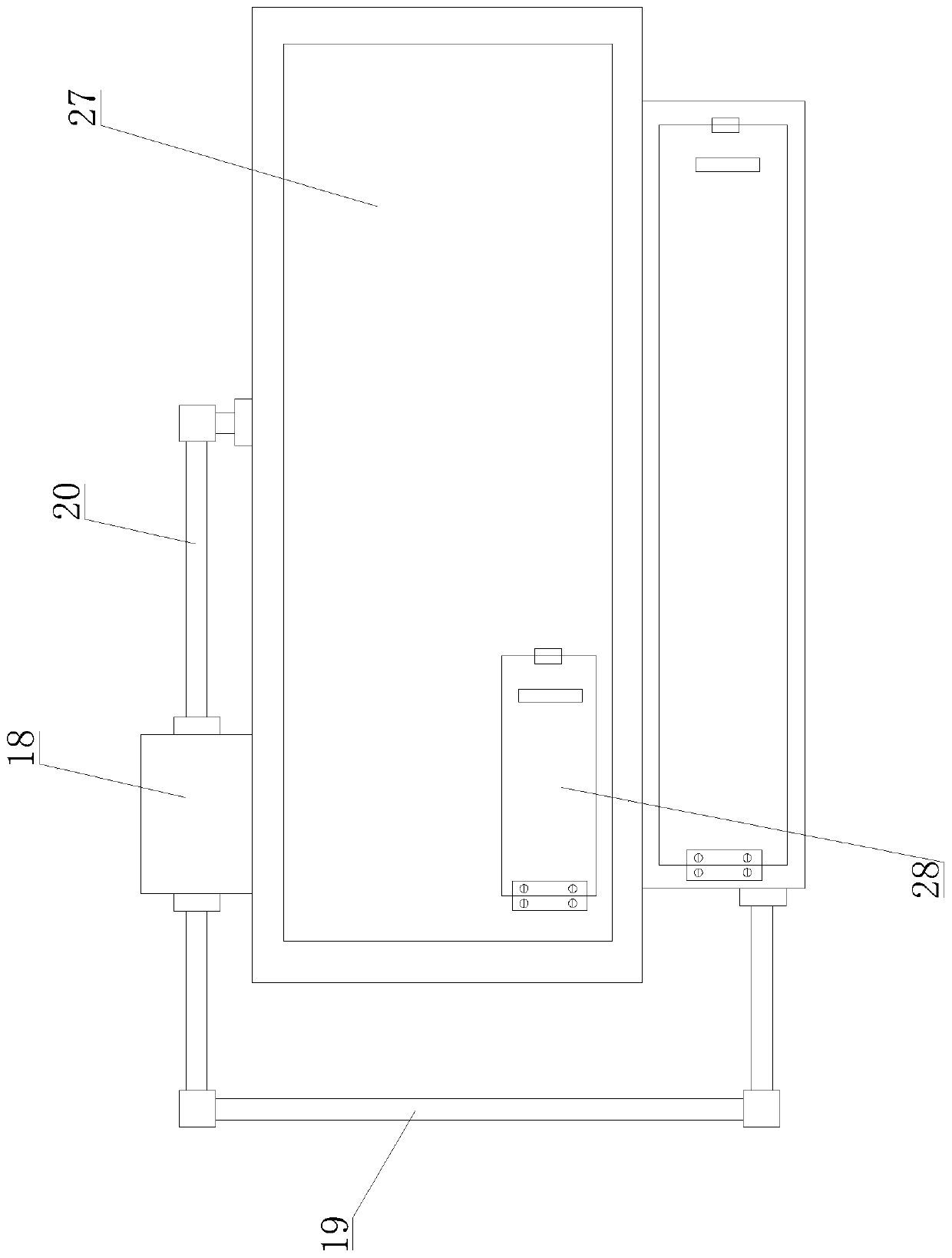

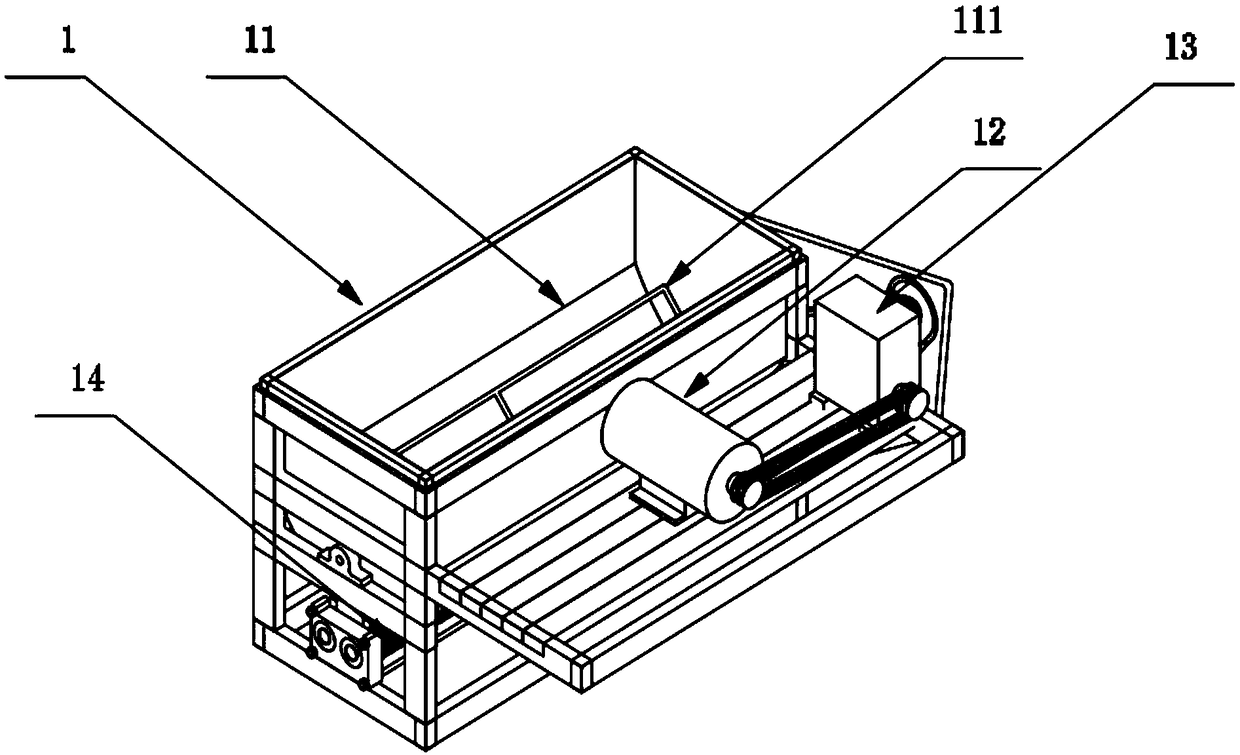

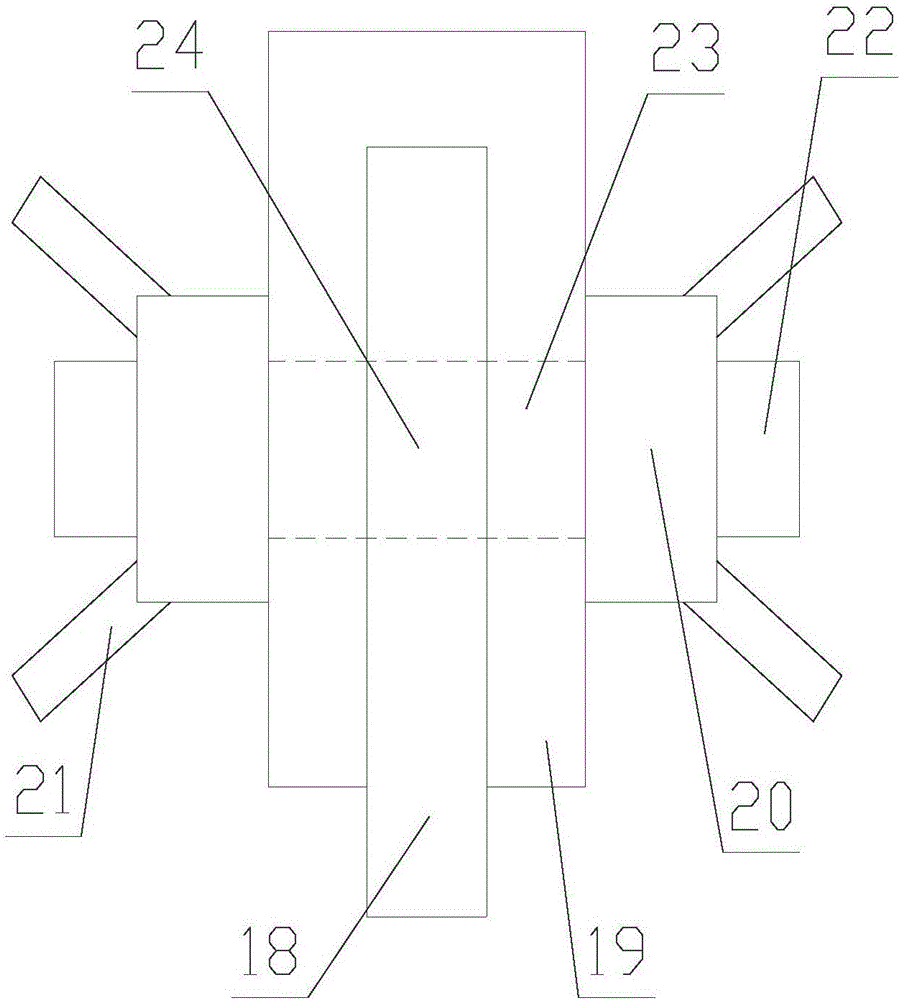

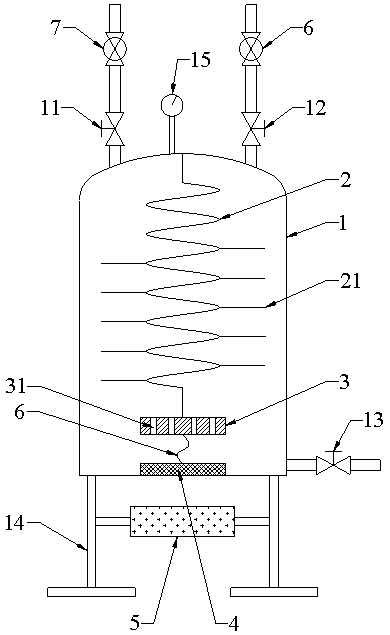

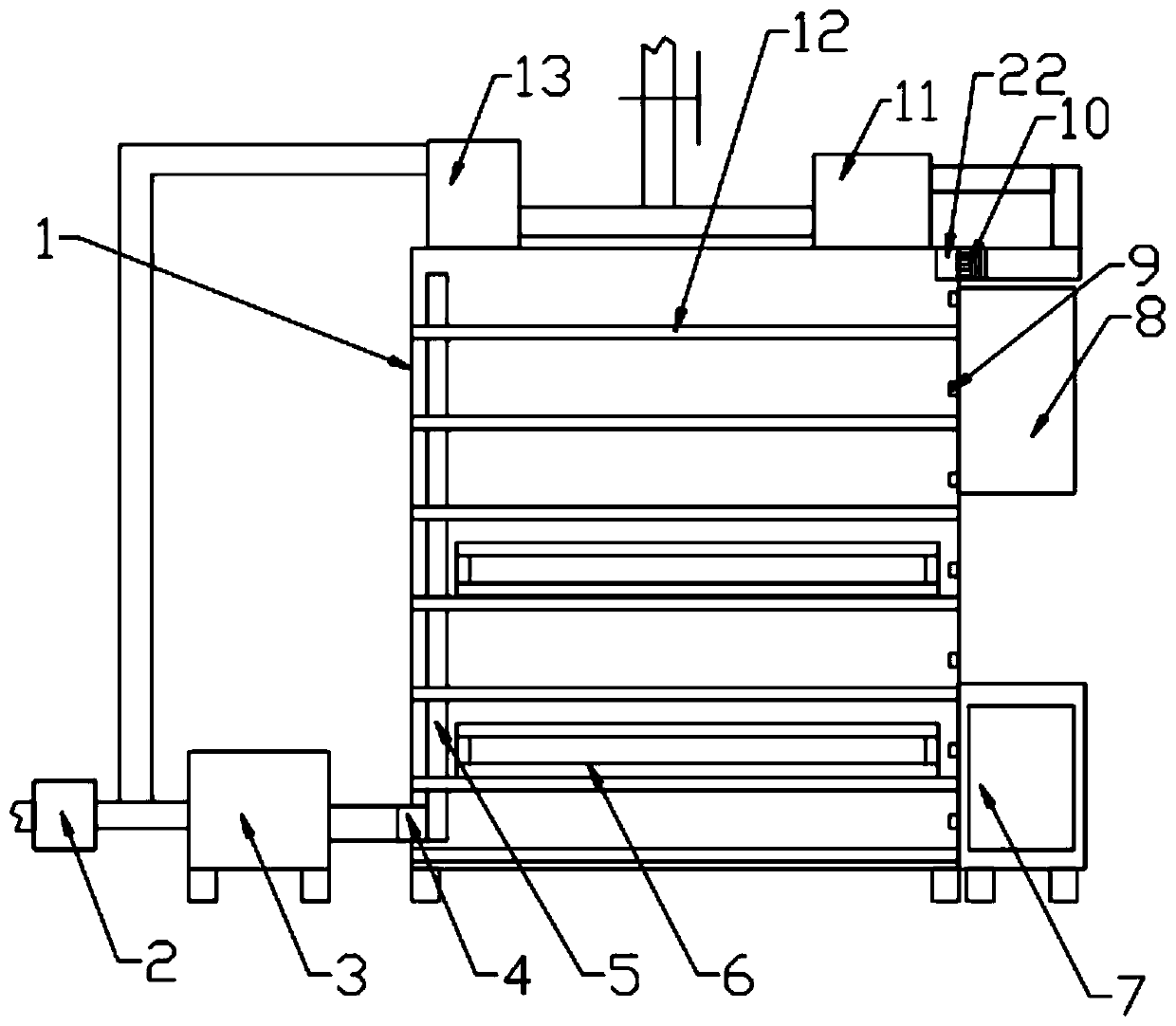

Energy-saving dryer and drying method thereof

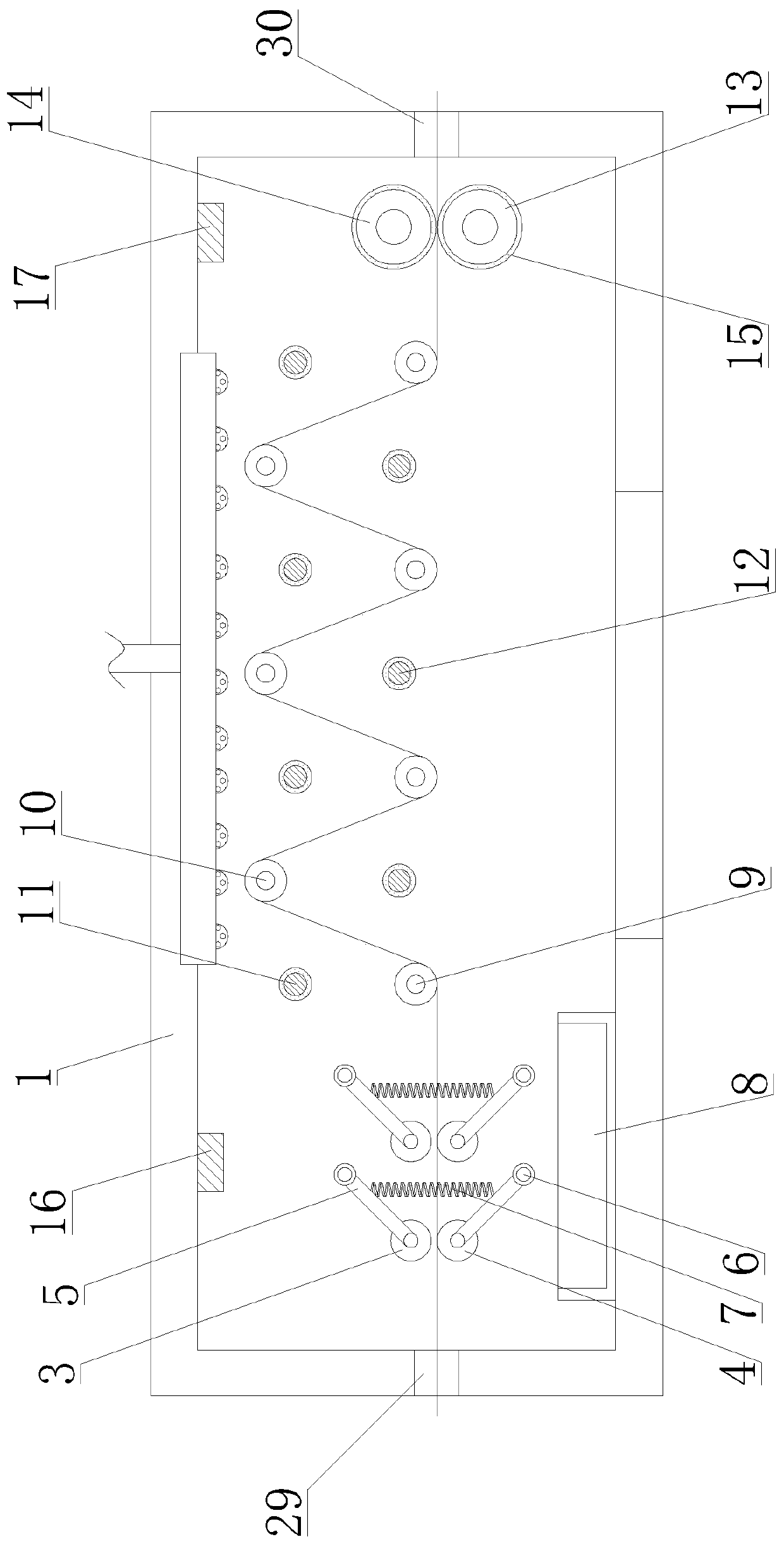

InactiveCN102183130AEasy to makeEasy drying operationDrying gas arrangementsDrying machines with progressive movementsBiochemical engineeringHeat energy

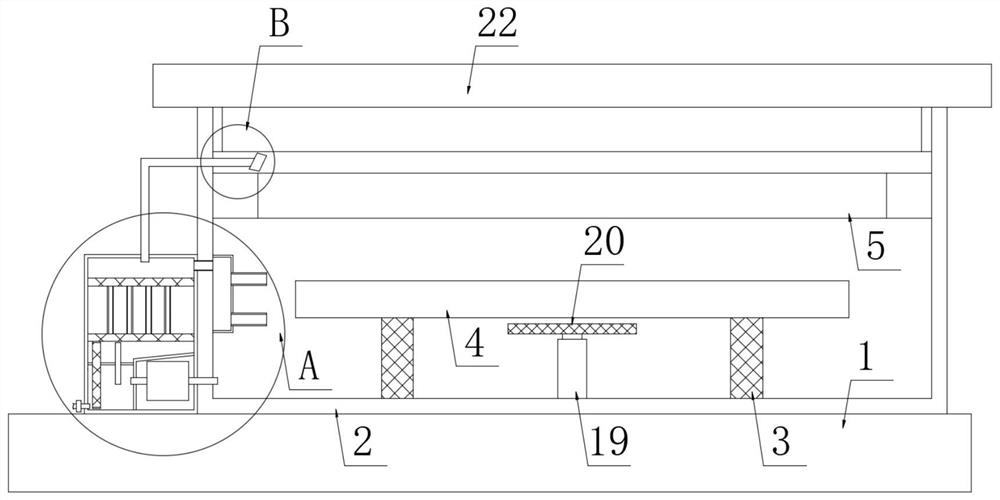

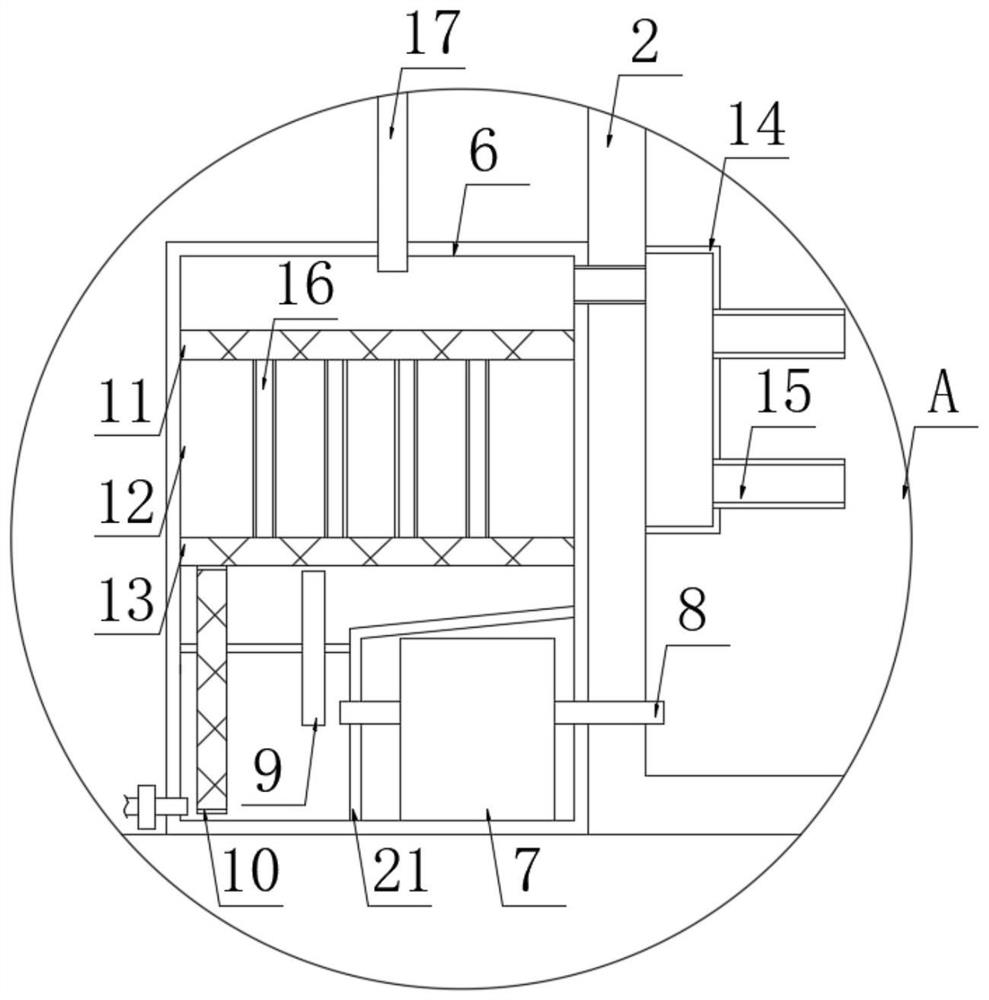

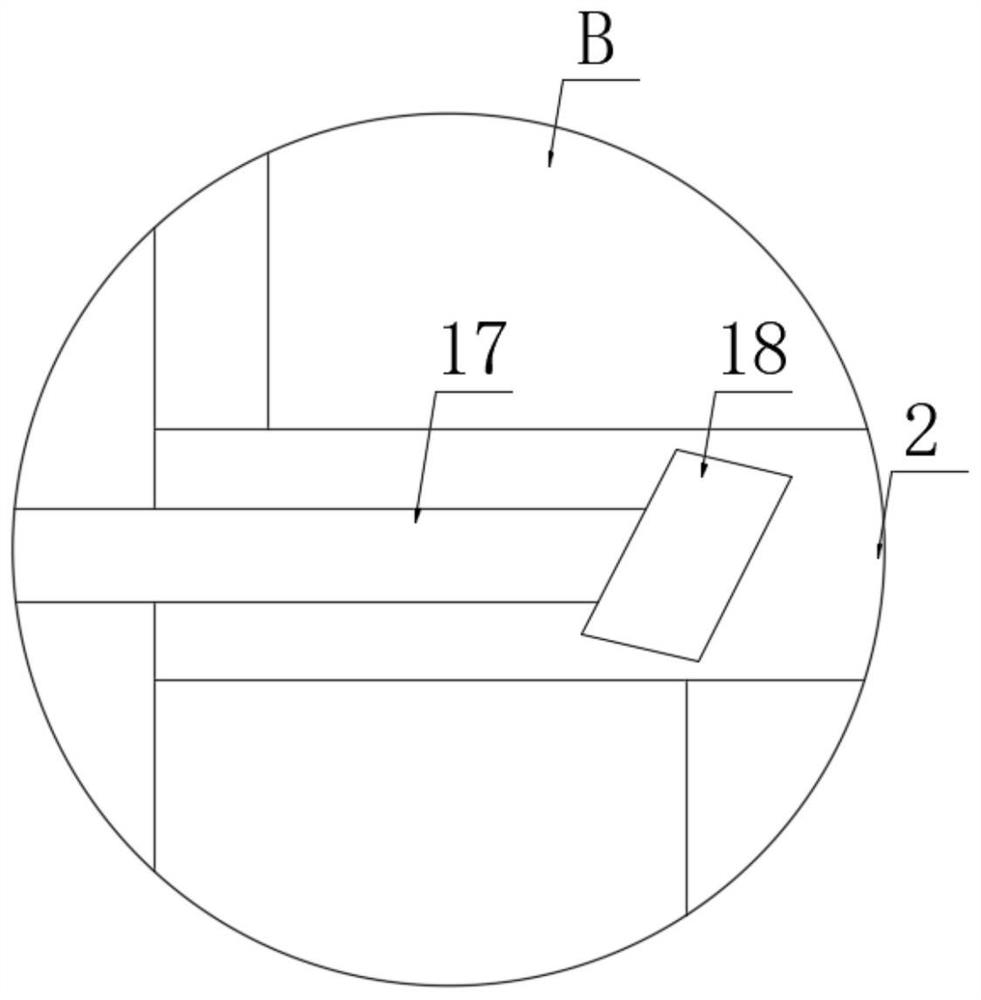

The invention discloses an energy-saving dryer and a drying method thereof. The energy-saving dryer mainly comprises a dryer main body, a transmission system and a heat energy exchanging system, wherein the dryer main body comprises a front part area 20 and a back part area 21 and the tail end of the front part area 20 is connected with the front end of the back part area 21; an emptying area 22 is arranged on the front end of the front part area 20 and a material receiving area 23 is arranged on the tail end of the back part area 21; and the transmission system is equipped between the front part area and the back part area and is used for driving the whole dryer. The heat energy exchanging system which is arranged on one side of the dryer comprises a heat exchanger, a draught fan and an air channel; and a movable door is arranged on the other side of the dryer. The invention provides the novel energy-saving dryer which has the advantages of simple structure, high efficiency and low consumption, stable production and convenience for repairing and clearing and also provides the drying method of the energy-saving dryer.

Owner:FUJIAN LAI KANG JIA FOOD DEV

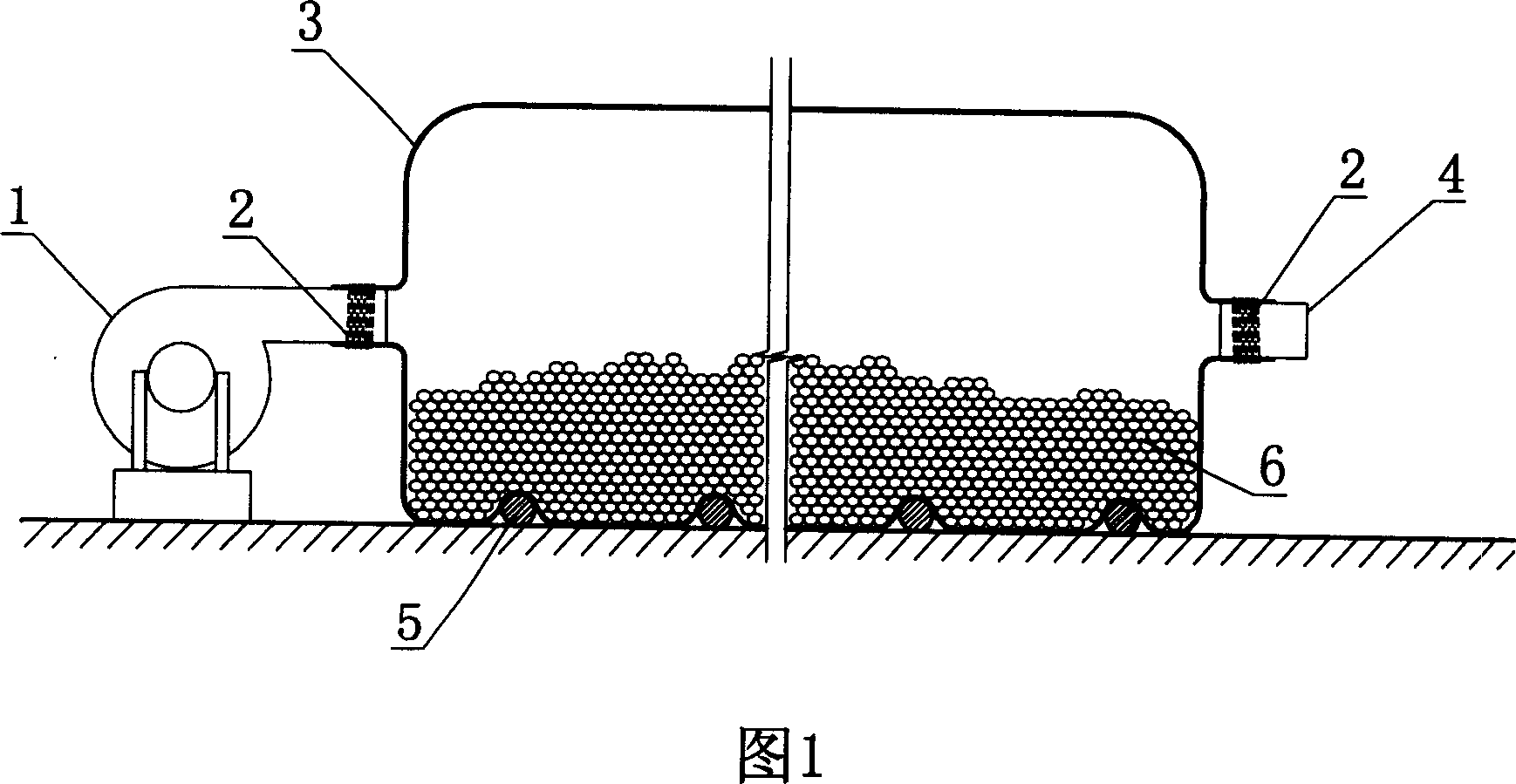

Pipe line type normal temperature dryer for dates

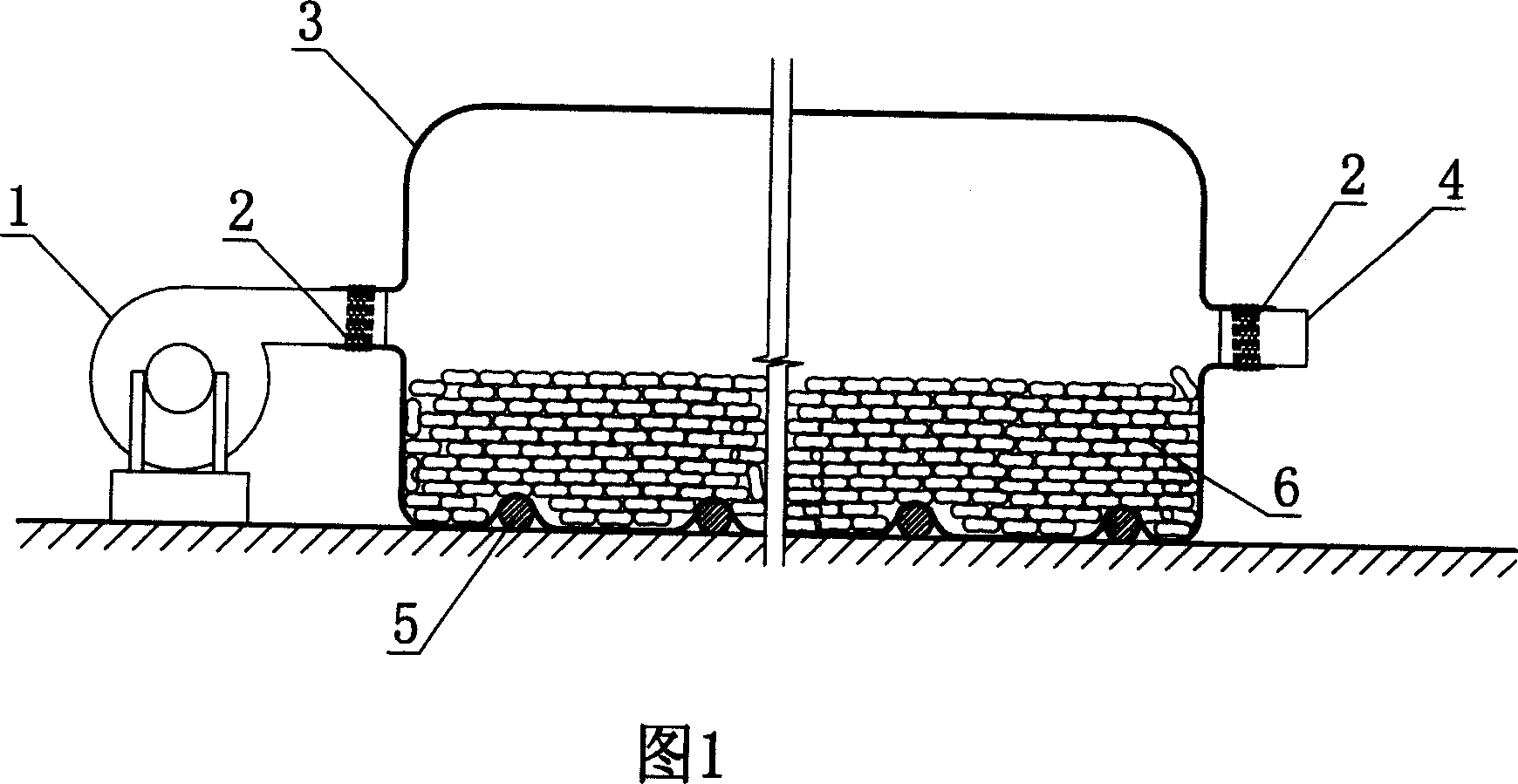

InactiveCN1948874AExcellent Flavor and QualityEasy dryingDrying solid materials with heatDrying machines with local agitationWater contentPlastic film

The invention supplies Chinese date pipeline type normal temperature dryer. It ties plastic film pipe at the output of the normal temperature fan, fills the Chinese date into the pipe, ties the output of the film pipe at hard outlet pipe, inserts stirring stick between the film pipe and the ground. The invention has the advantages of low investment, simple operation, easy controlling, litter powder expenditure, better flavor for dried Chinese date than heat drying.

Owner:SICHUAN UNIV

Preparation method of instant Maojian tea capable of building bodies

The invention relates to a method for preparing instant Maojian tea capable of building bodies from black Maojian tea as a raw material, belonging to the technical field of health beverages, and solving the problems of large granules, poor instant solubility, low nutritional value and poor mouth feel of existing Maojian tea capable of building bodies. The method comprises the concrete steps of adding water for soaking the black Maojian tea raw material; adding tannase, cellulase and pectinase for enzymatically hydrolyzing; adding beta-cyclodextrine and sodium hydrogen sulfite for well extracting effective ingredients from the raw materials; removing impurities; concentrating; drying; packaging. The method is simple in process. The instant Maojian tea prepared by adopting the method is high in effective ingredient content, moderate in tea granule size, good in porosity, convenient to dissolve in water, fresh and bright in tea soup color, rich in fragrance, and fragrant and slightly sweet in mouth feel.

Owner:山西林业职业技术学院

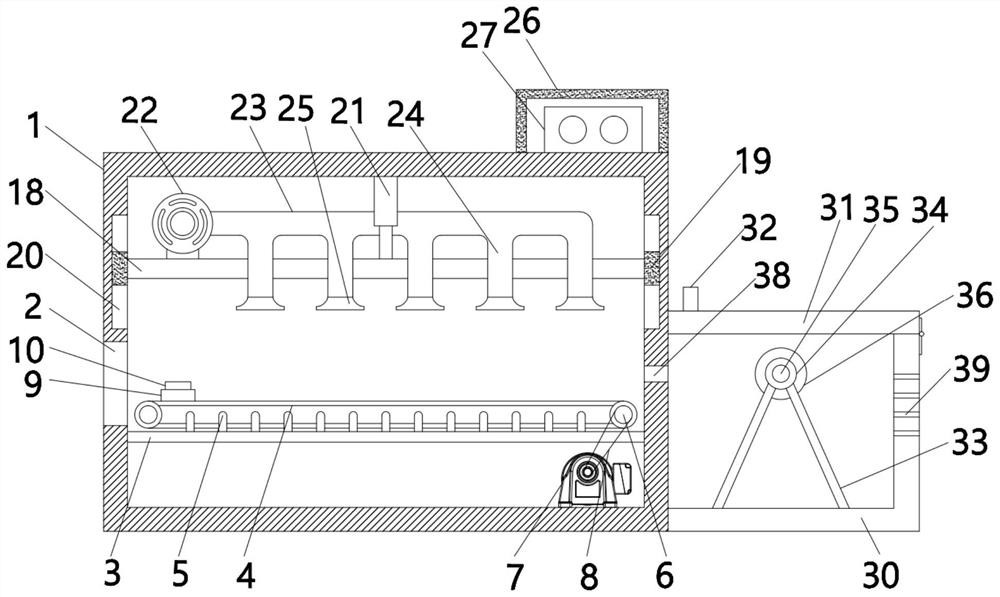

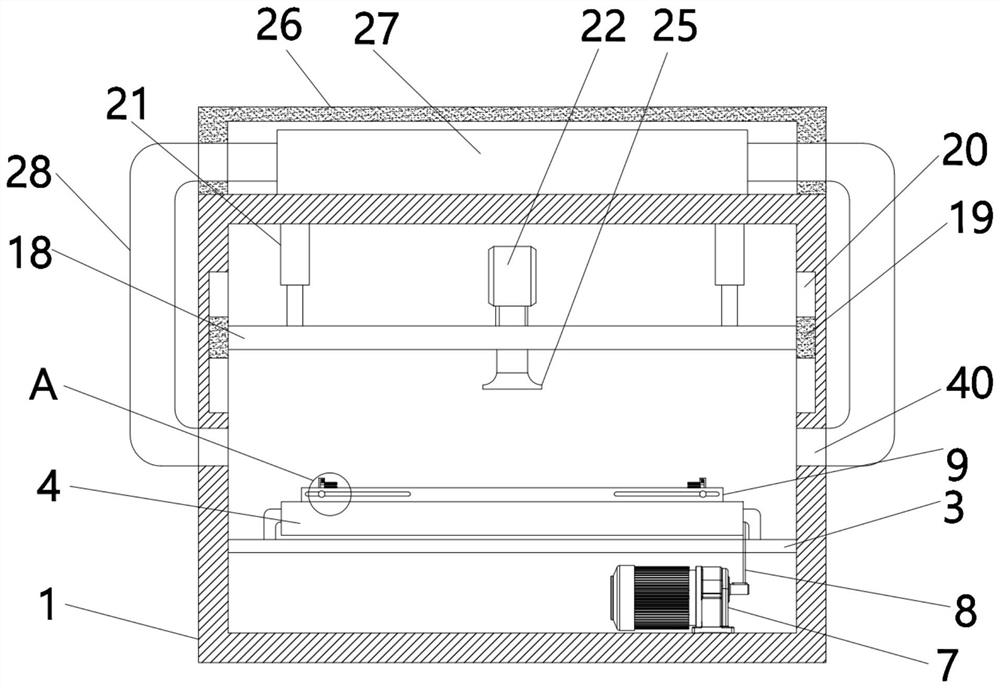

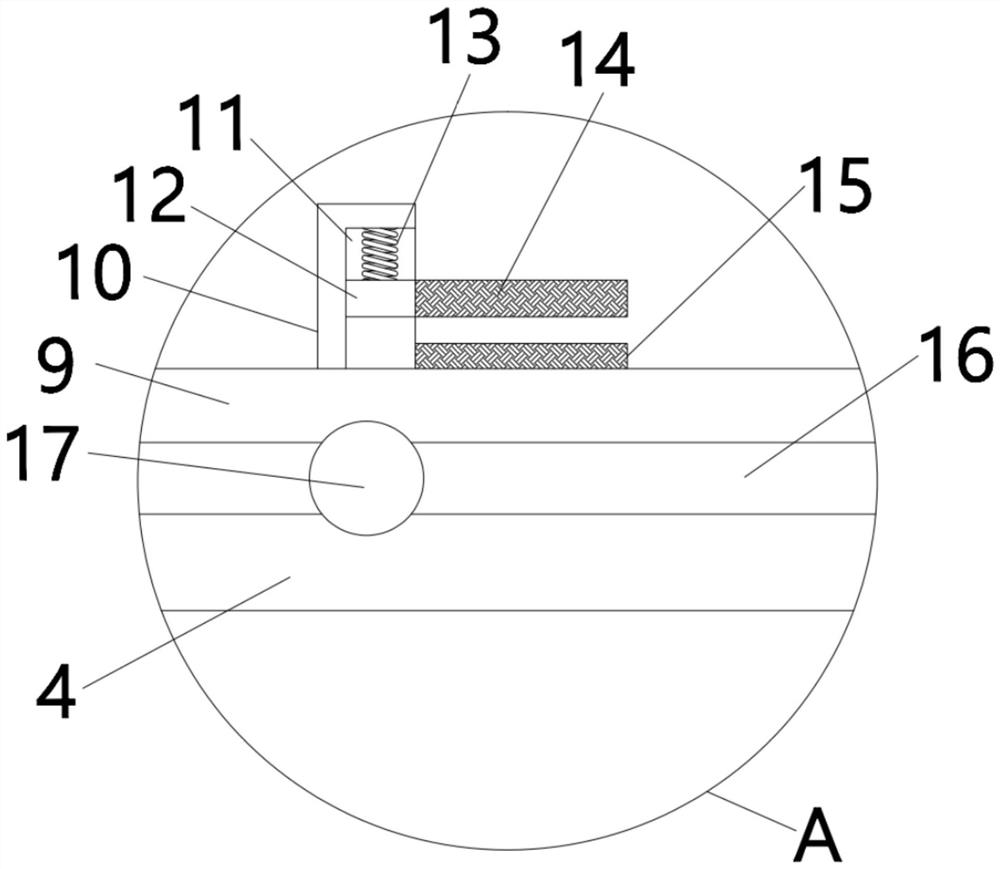

Automatic drying device for special polyester knitted fabric processing

InactiveCN110360824AEasy to operateImprove drying efficiencyDrying gas arrangementsDrying chambers/containersPolyesterEngineering

The invention belongs to the technical field of polyester knitted fabric processing, and particularly relates to an automatic drying device for special polyester knitted fabric processing. In order tosolve the problems that an existing drying device is low in drying efficiency, poor in drying effect andinconvenient to operate, and wasting time and effort, theautomatic drying device in the following scheme comprises a drying box, a dehumidifying box and a wringing assembly, wherein the wringing assembly is located in the drying box and is located at the position close to an input port; a firstguiding roller and a second guiding roller are arranged in the drying box and are arranged at an interval; the first guiding roller is located under the second guiding roller; a first heating elementand a second heating element are arranged at an interval; a first conveying roller and a second conveying roller compress polyester knitted fabric; the dehumidifying box is arranged on the bottom part of the drying box; an air exhauster is arranged on the drying box; an input pipe is connected with the dehumidifying box and the air exhauster; and an output pipe is connected with the air exhausterand a connecting piece. The automatic drying device for special polyester knitted fabric processing provided by the invention is simple to operate, savestime and effort, and is high in drying efficiency, good in drying effect, and capable of playing a role in saving energy consumption and protecting the environment.

Owner:江苏鹏翔新材料科技股份有限公司

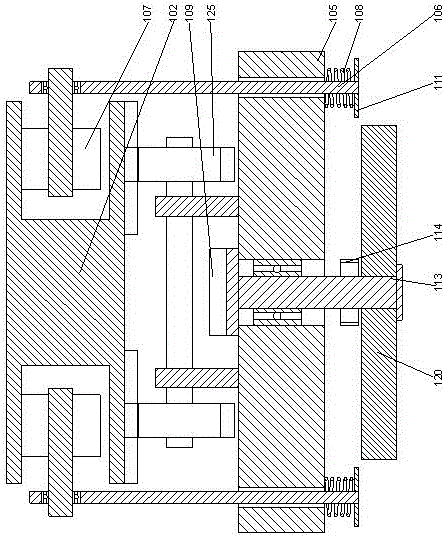

Automatic disinfecting and drying machine

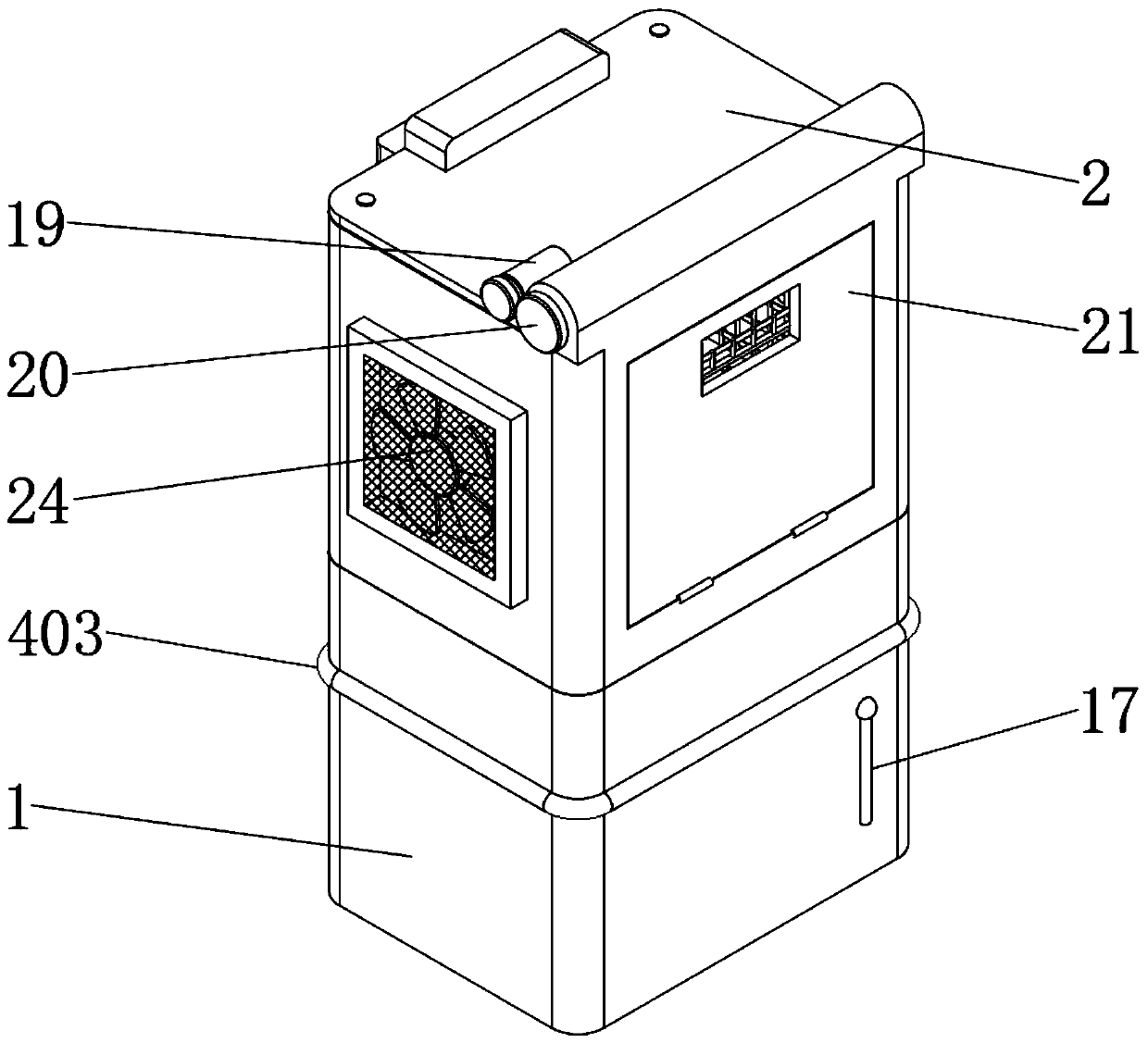

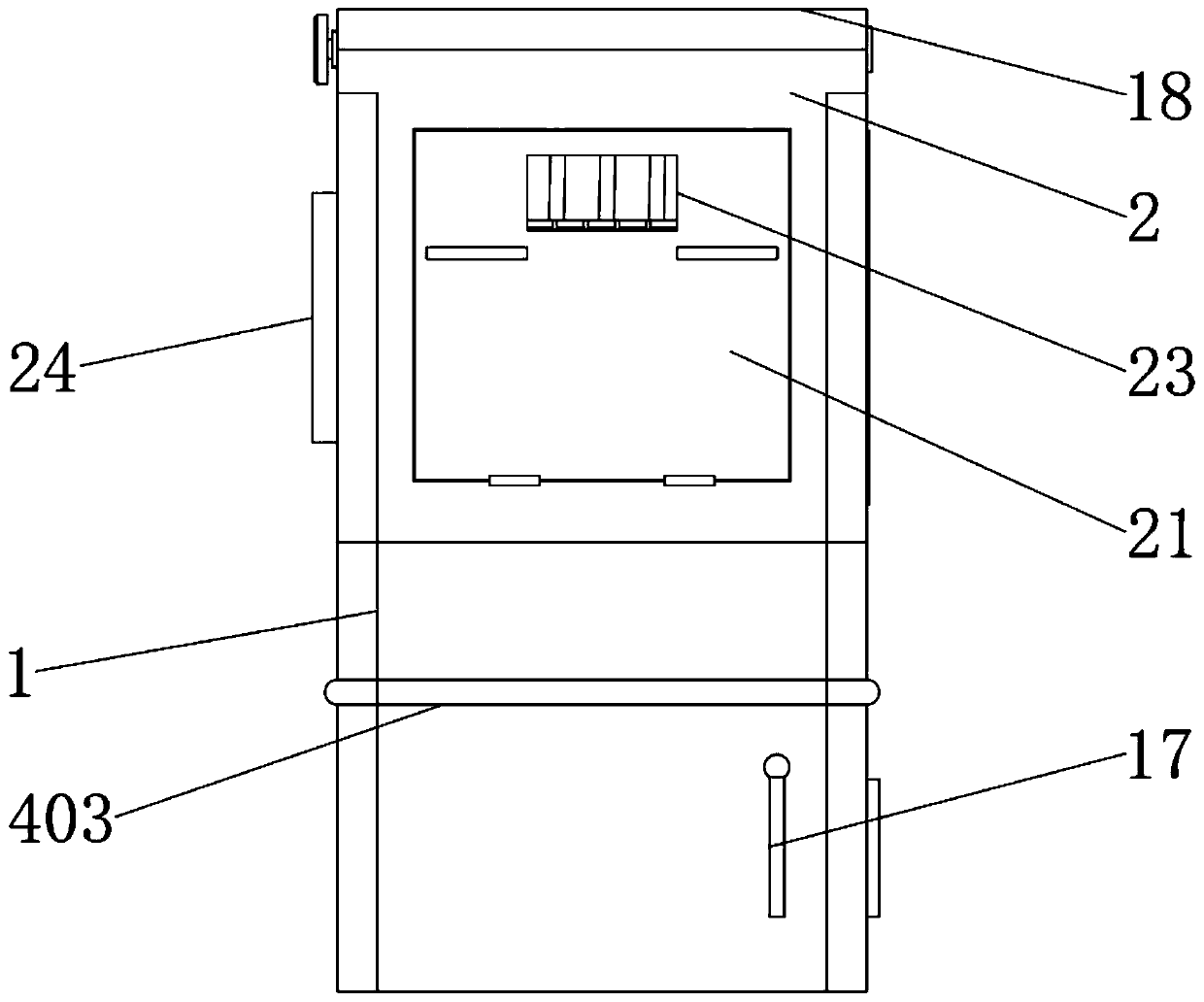

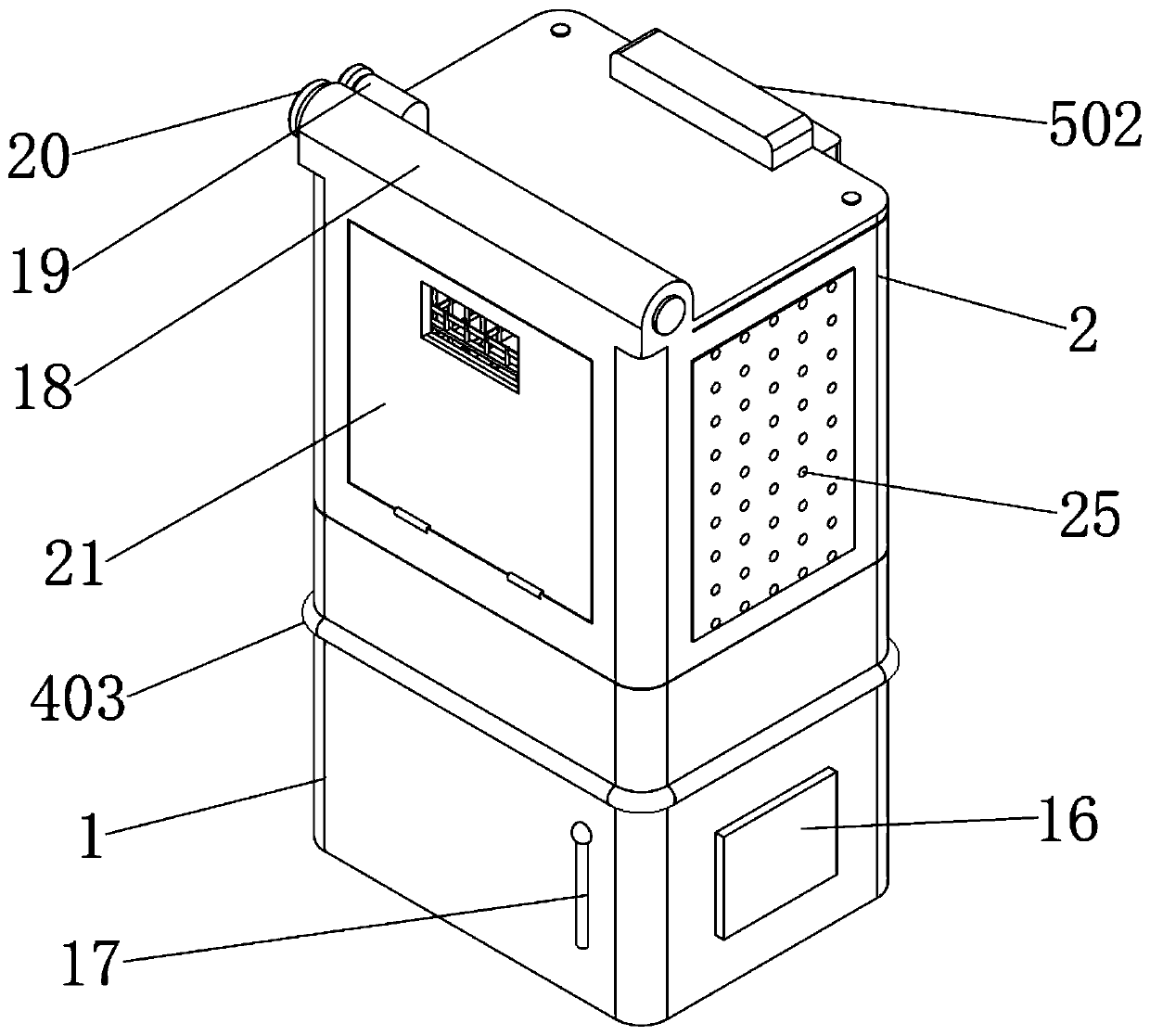

PendingCN111397323ATo achieve the purpose of disinfection and drying integrationEasy drying operationLavatory sanitoryDrying machines with local agitationEngineeringMechanical engineering

The invention discloses an automatic disinfecting and drying machine. The machine comprises a disinfecting box, a drying box, a lifting basket, a spraying device, a heating device and baffles, whereinthe bottom of the drying box is connected to the upper end of the disinfecting box in a sleeving mode, threaded rods are rotationally connected to the front end of the interior of the drying box, guiding rods are fixedly connected to the rear end of the interior of the drying box, the bottoms of the guiding rods and the bottoms of bearing seats are fixedly connected into the disinfecting box, moving seats are fixedly connected to the four corners of the lifting basket, the threaded rods and the guiding rods are inserted into the moving seats, a spring rotating shaft is fixedly connected between fixing blocks, sleeves are fixedly connected to one ends of the baffles, and the sleeves are connected to the outer side of the spring rotating shaft in a sleeving mode, the spraying device is arranged at one end of the disinfecting box, and the heating device is fixedly connected to the upper end of the drying box. According to the automatic disinfecting and drying machine, the threaded rods,the guiding rods, the rotating rod and bevel gears are arranged in a matched mode, so that the lifting basket moves back and forth between the disinfecting box and the drying box, and the purpose of disinfecting and drying integration is achieved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

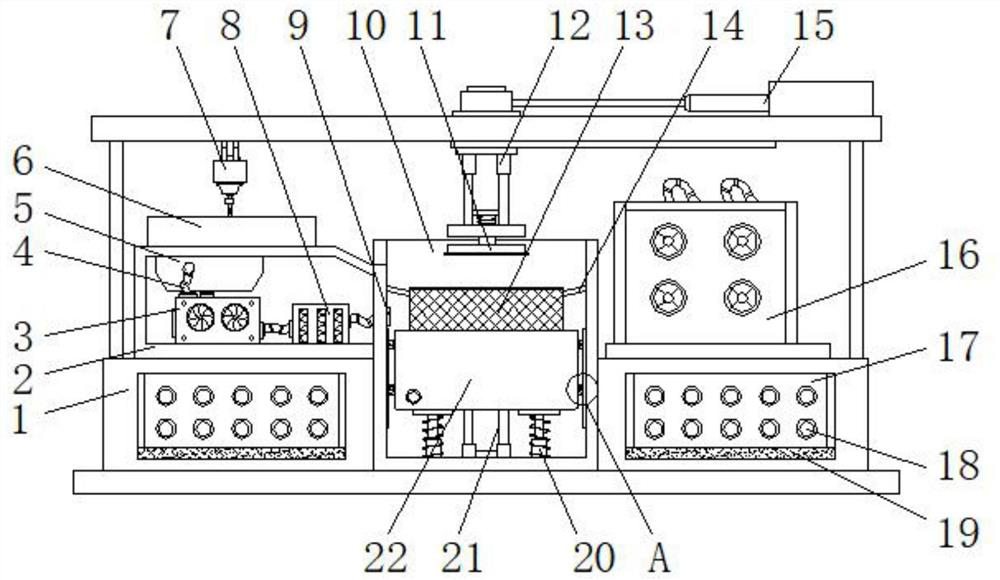

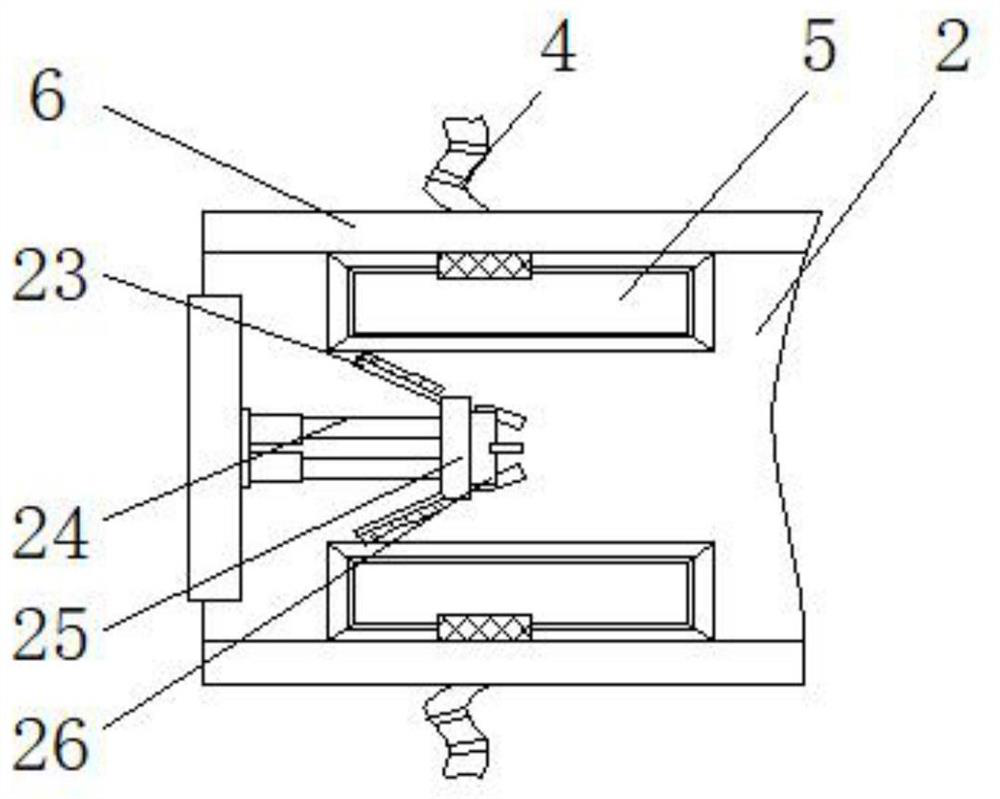

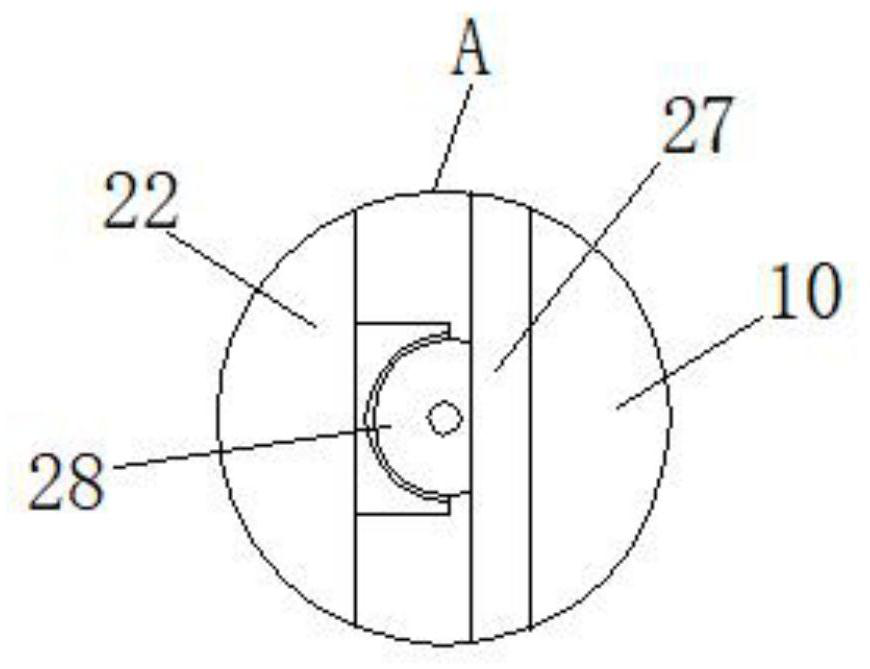

Multi-stage processing device for high-speed train seat parts

InactiveCN111823020AEasy to dryEasy to moveDrying gas arrangementsCleaning using toolsWater storageWater storage tank

The invention discloses a multi-stage processing device for high-speed train seat parts, and belongs to the technical field of high-speed train seat production. The device comprises a device main body, a drilling table is fixedly connected to the lower surface of the inner wall of the device main body, and an exhaust fan is fixedly connected to the lower surface of the inner wall of the drilling table. According to the multi-stage processing device for the high-speed train seat parts, a heating mechanism, an electromagnet, a first hydraulic rod, a mesh box, a second hydraulic rod, a third hydraulic rod and a water storage box are arranged; through the cooperation of the mesh box and the water storage box, the parts can be directly cleaned after being drilled; through cooperation of the exhaust fan and the heating mechanism, the parts are directly dried after being cleaned; and through the cooperation of the electromagnet, the first hydraulic rod and the second hydraulic rod, the partscan be adsorbed and conveniently and directly moved into a spraying mechanism for spraying, so that the tedious process can be effectively reduced, the operation is convenient, and the processing efficiency is improved.

Owner:HUBEI DERUI SITONG TECH

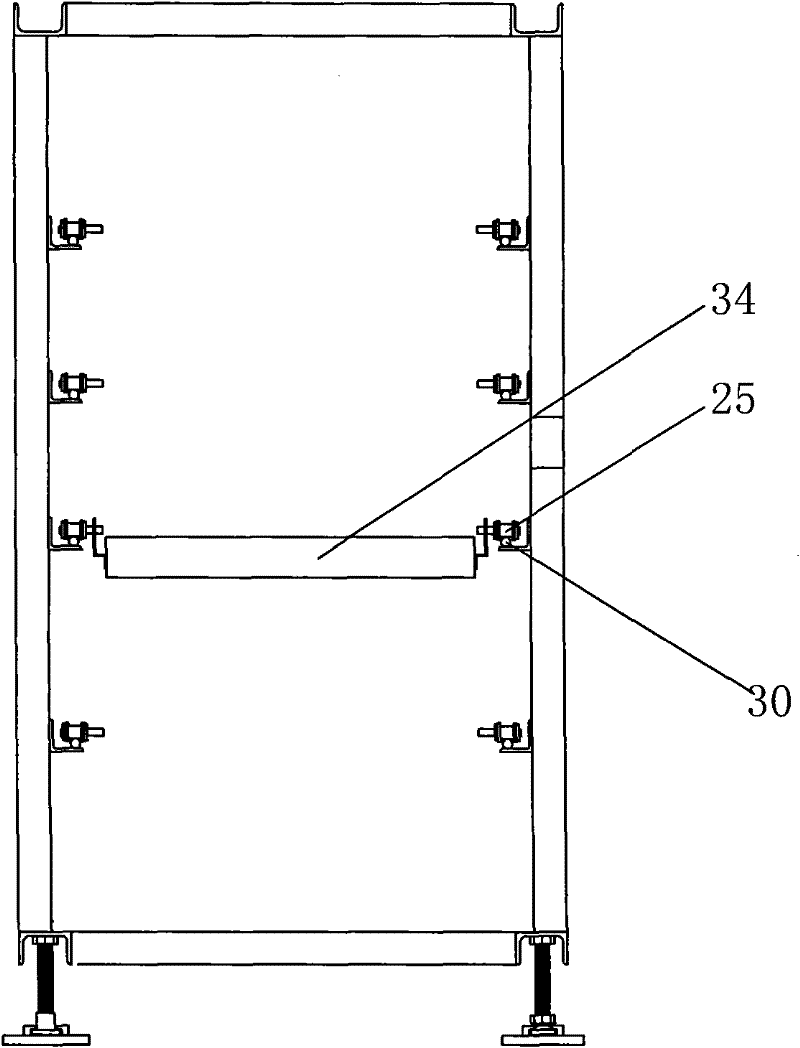

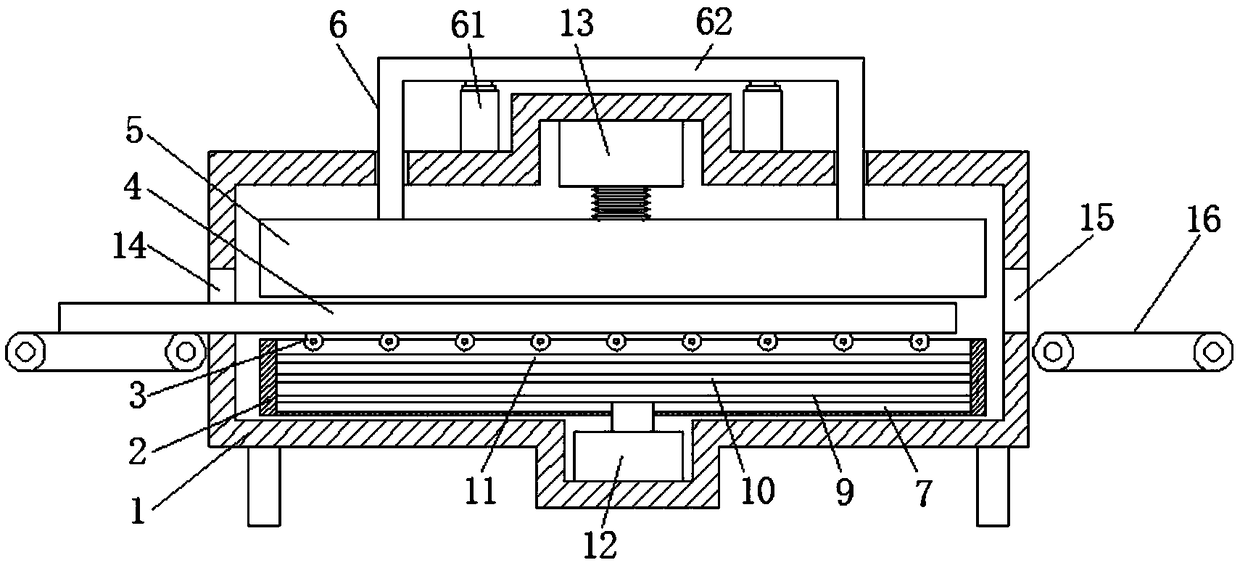

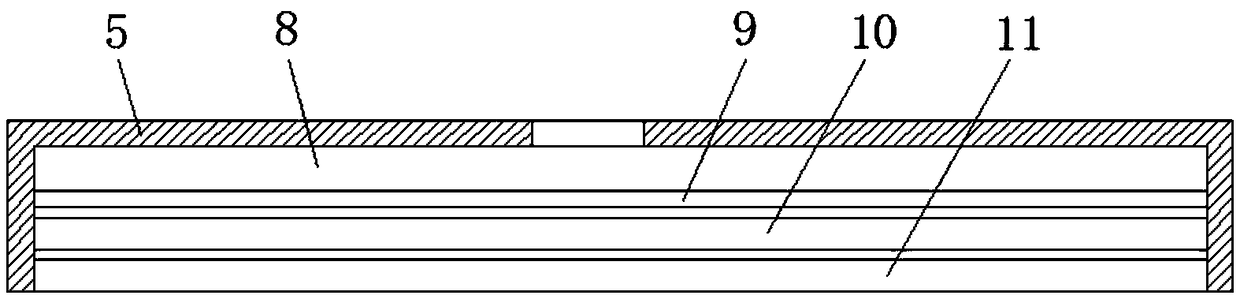

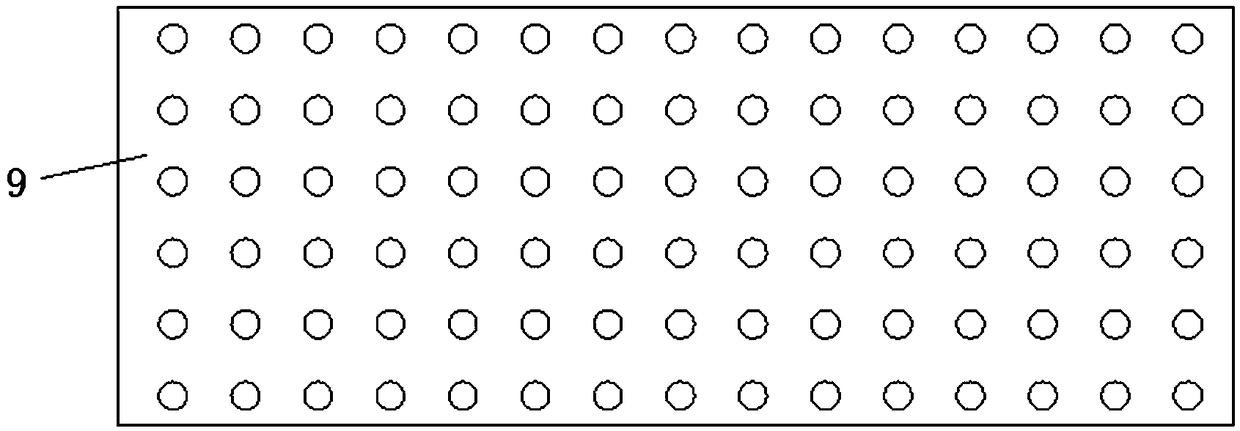

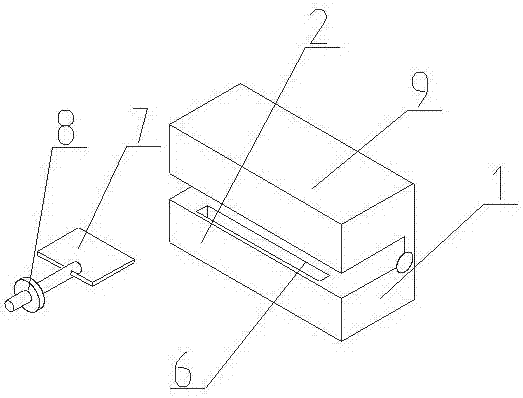

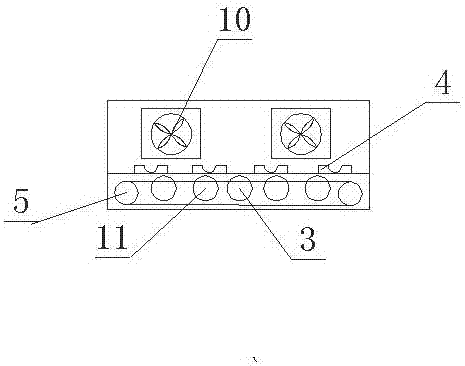

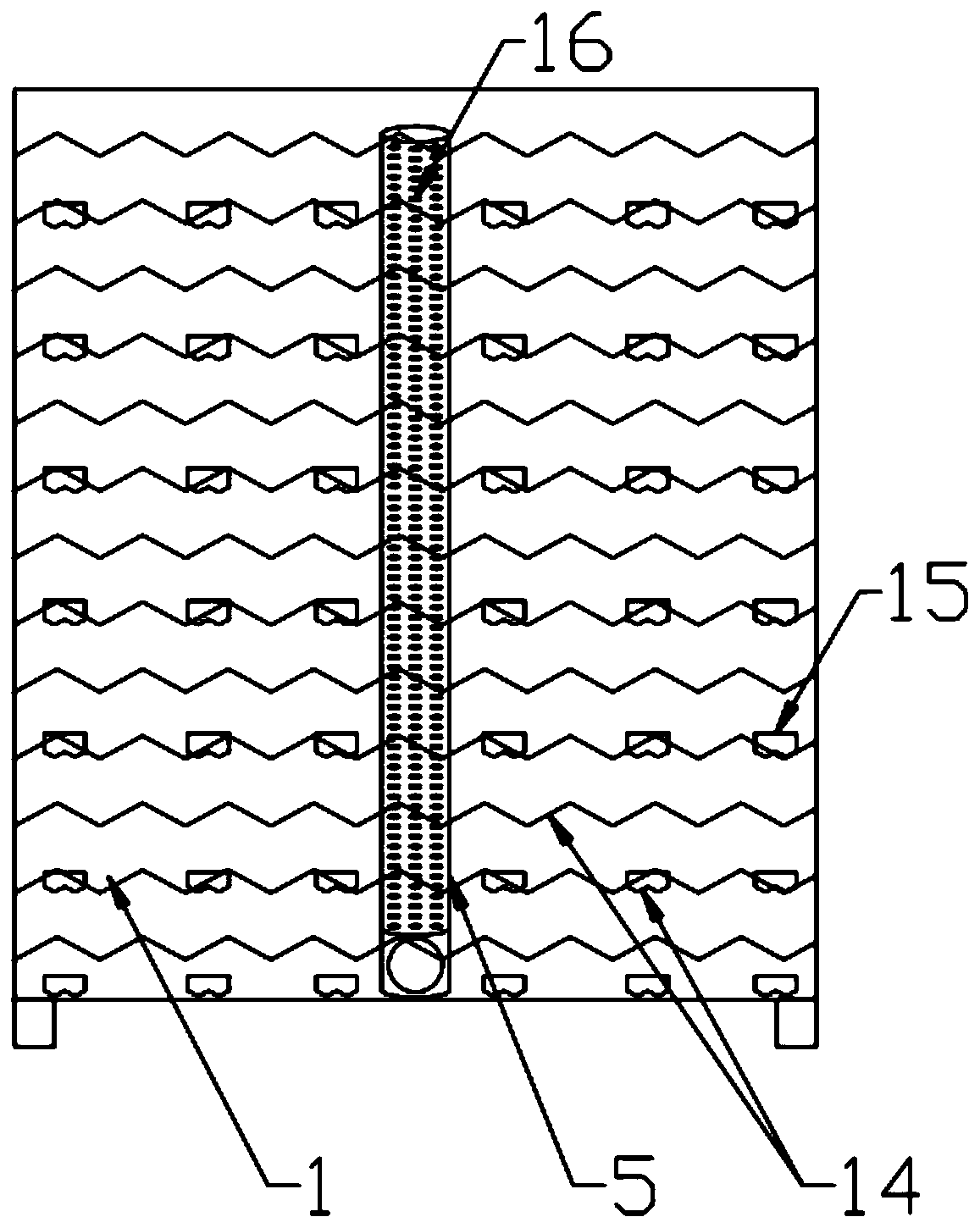

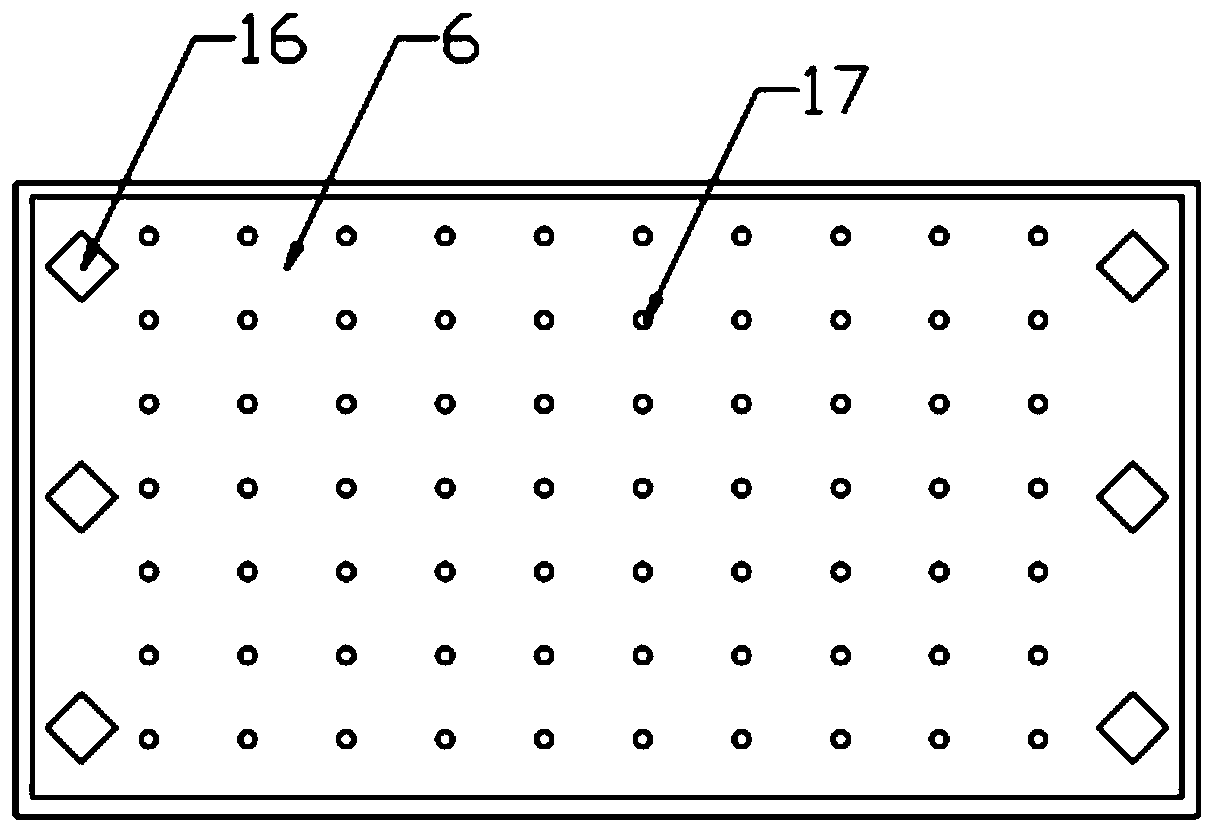

Plate drying device for processing of purifier

InactiveCN108816691AWide range of applicationsUniform drying temperaturePretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a plate drying device for processing of a purifier. The plate drying device comprises a drying box body; the internal bottom of the drying box body is provided with a lower drying box; the top of the lower drying box is rotationally connected with transmission rollers which are distributed at an equal interval; a plate is placed on the transmission rollers; an upper dryingbox is arranged over the plate; one side, far away from the plate, of the upper drying box is connected with a lifting device; the centers of the sides, far away from the plate, of the lower drying box and the upper drying box are correspondingly provided with a lower air distribution chamber and an upper air distribution chamber; and one side, far away from the plate, of the lower air distribution chamber is connected with an air outlet of a first fan through a straight pipe. According to the plate drying device disclosed by the invention, a lifting device can be used for controlling the height of the upper drying box so as to realize drying of the plates which are different in thickness; the plate drying device is wide in application range; meanwhile by utilizing a second air distribution plate of which the air distribution holes are gradually changed, the drying air power to the plate can be gradually increased; the paint, which is not dried completely, on the surface of the plate is prevented from being wrinkled by blowing; and the plate drying device is good in drying effect and high in quality.

Owner:王利琴

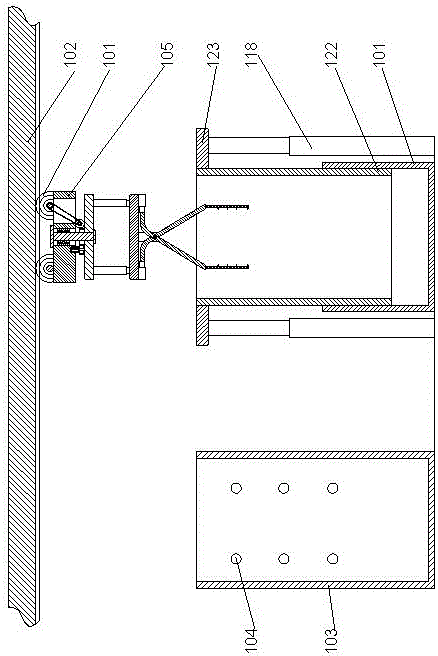

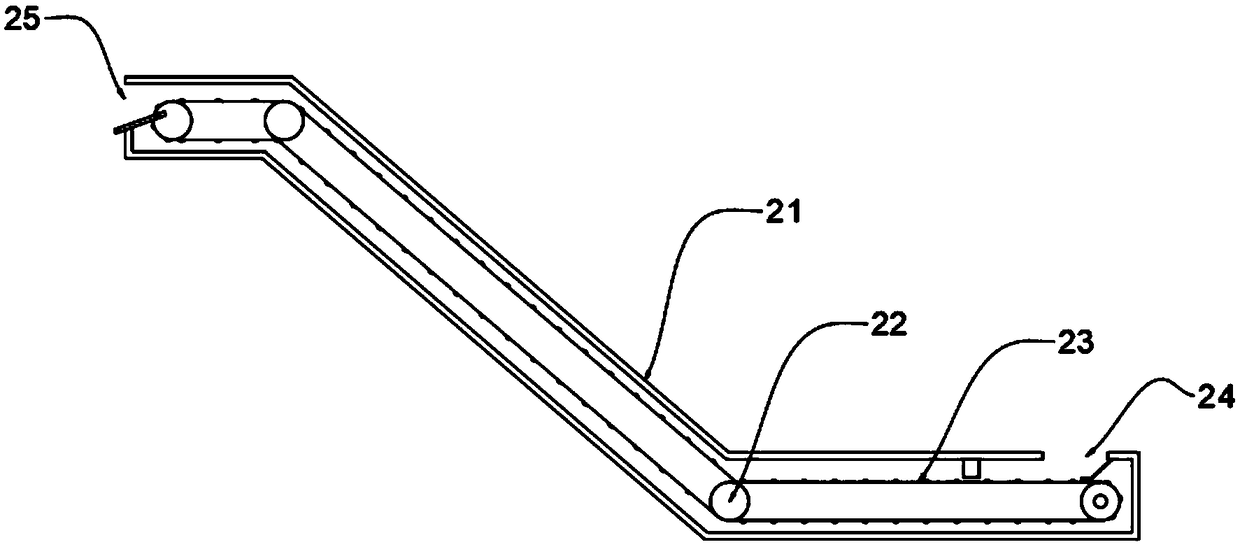

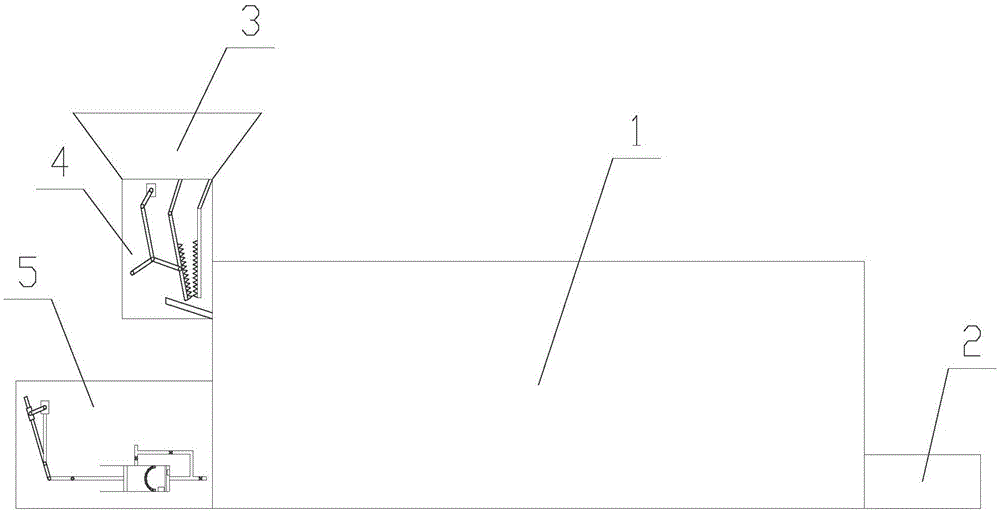

Automatic forage turning and drying device

InactiveCN107144112AEasy to moveReasonable structural designGrass dryingDrying machines with progressive movementsEngineeringWindshield

The invention discloses an automatic turning and drying device for forage, which includes a base, a furnace chamber is arranged on the base, a heating module is arranged in the furnace chamber, and a groove is arranged on the surface of one end of the furnace chamber. The furnace cavity is provided with a chain group, the other end surface of the furnace cavity is provided with a groove, and the chain group is arranged at the lower end of the groove, and the furnace cavity is provided with a drying rack. The drying frame is provided with a gear connected to the chain group, the furnace cavity is provided with a windshield, and a fan is provided on one side of the windshield; the device has reasonable structure design, simple operation, safety and reliability, and realizes Multiple groups of drying racks can be dried at the same time, which greatly reduces the cost and achieves the convenience of moving the rolling drying furnace.

Owner:合肥源行农业科技有限公司

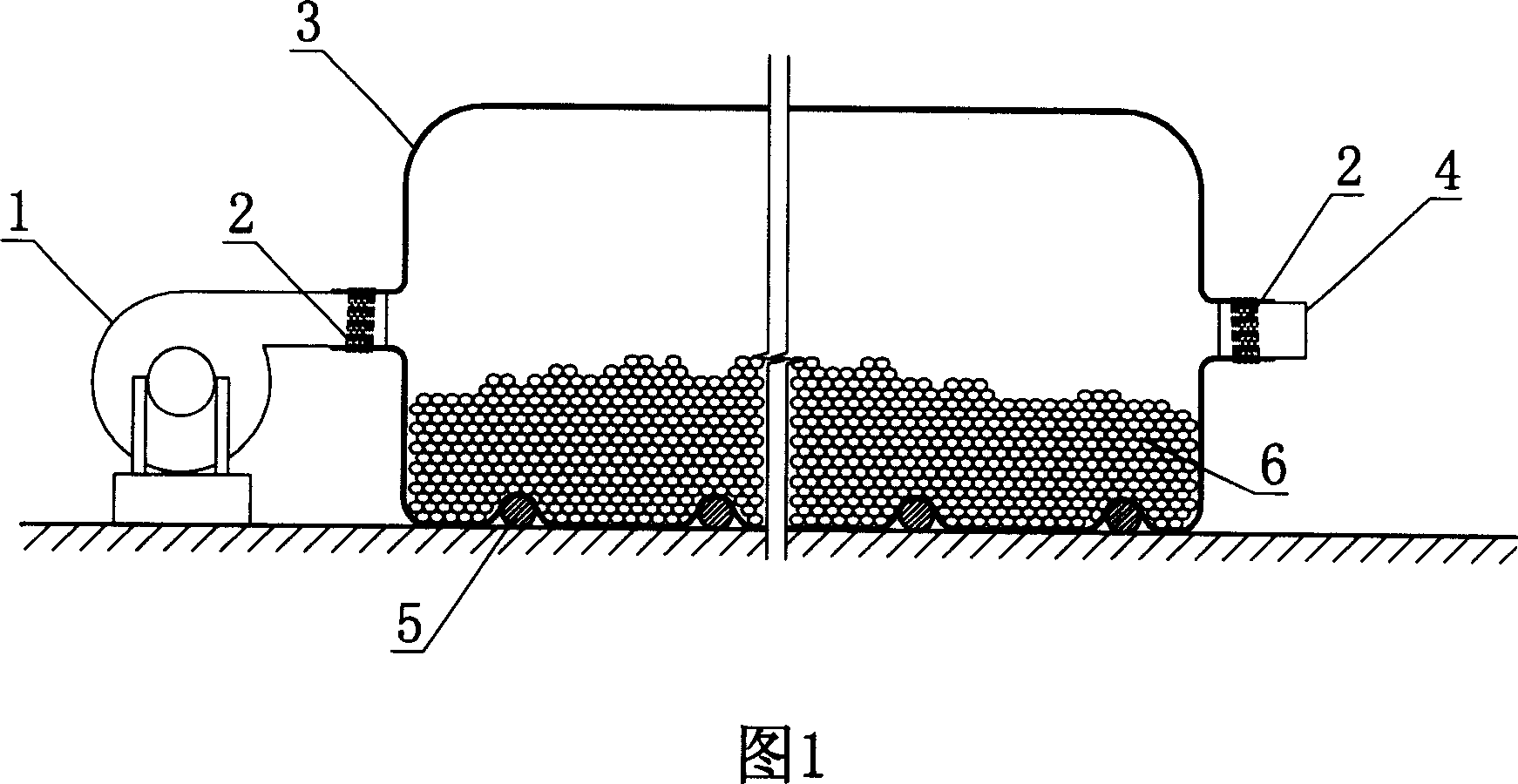

Conduit type normal temperature dehumidifier for peanut

InactiveCN1957719AReduce power consumptionEasy drying operationFruit and vegetables preservationEngineeringPlastic film

An ordinary-temp pipeline drier for peanut features that a plastic film pipe in which the peanuts are loaded has one inlet connected with the outlet of ordinary-temp blower by binding and one outlet bound to a hard pipe, and a stirring rod is transversely inserted between film pipe and ground.

Owner:SICHUAN UNIV

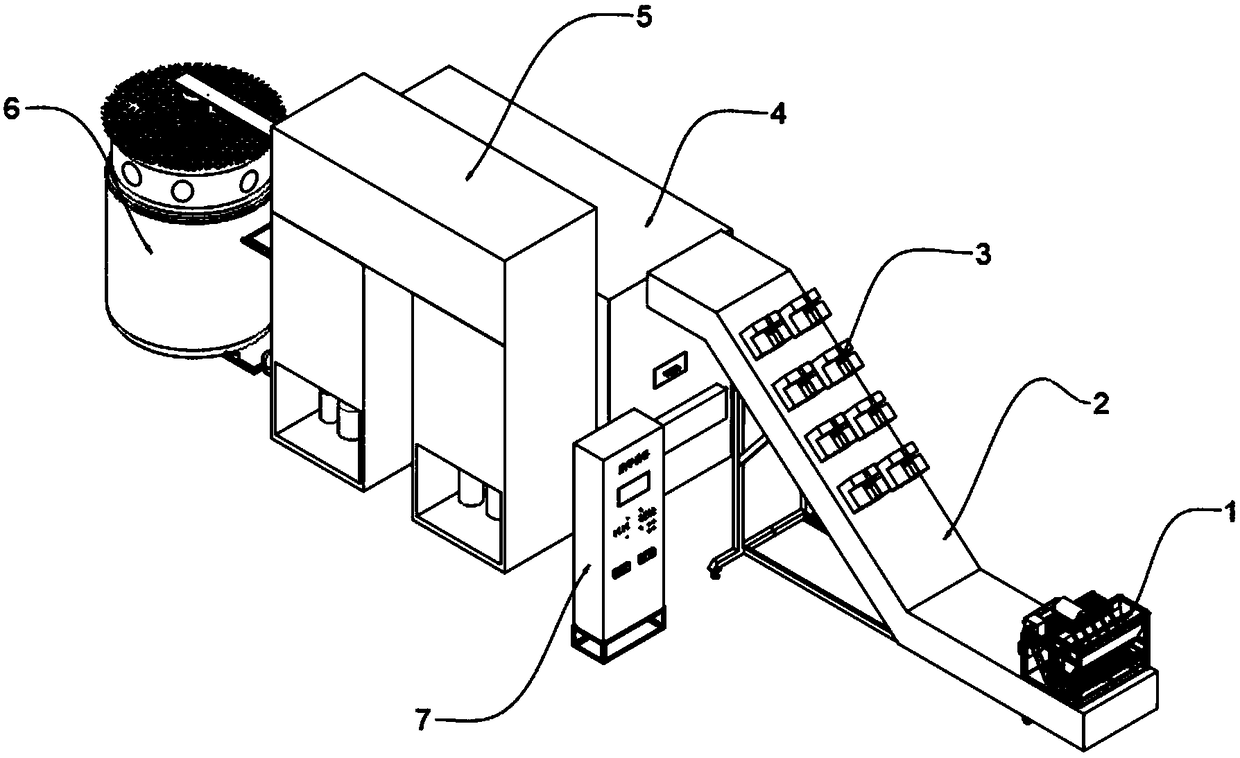

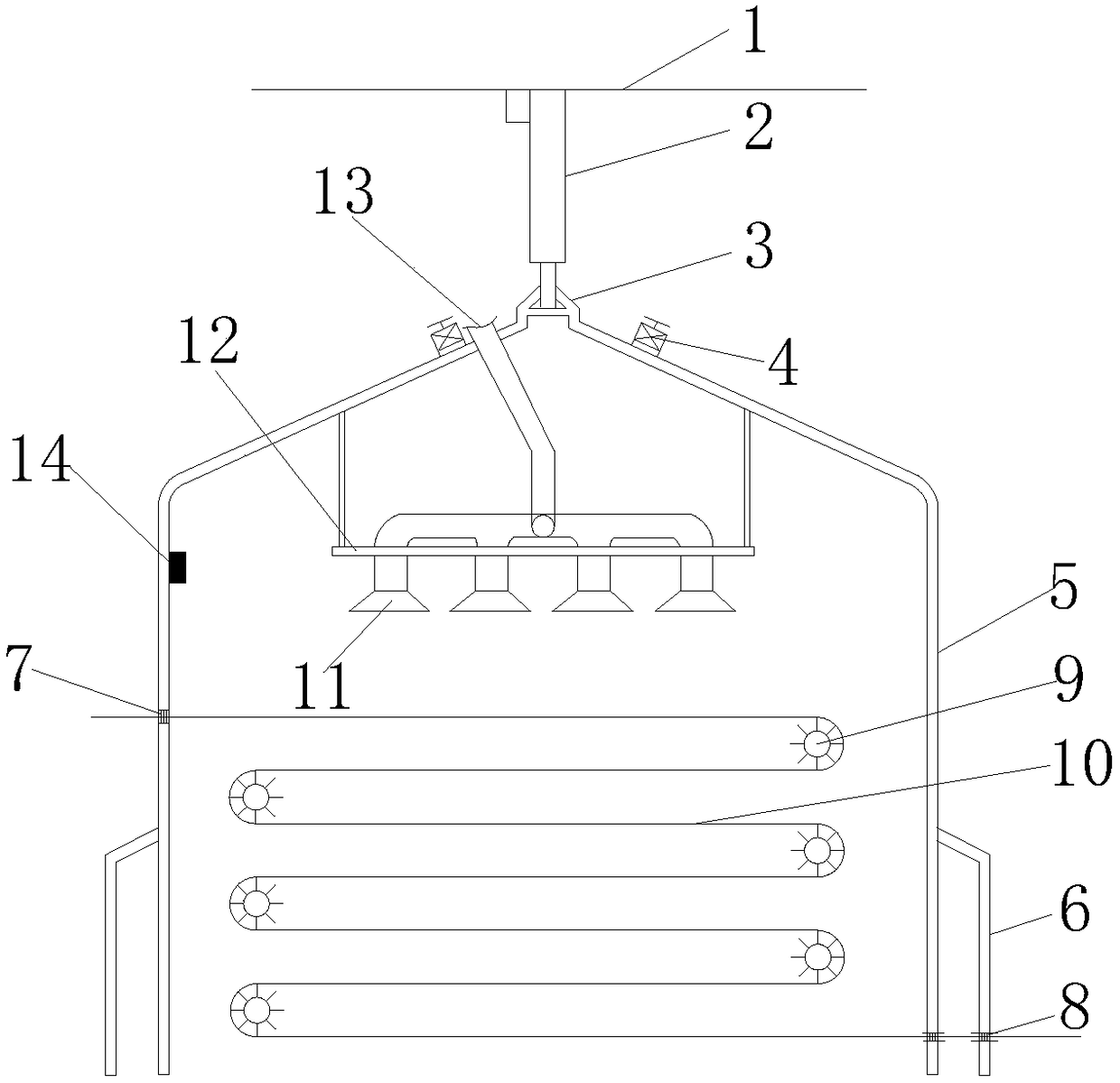

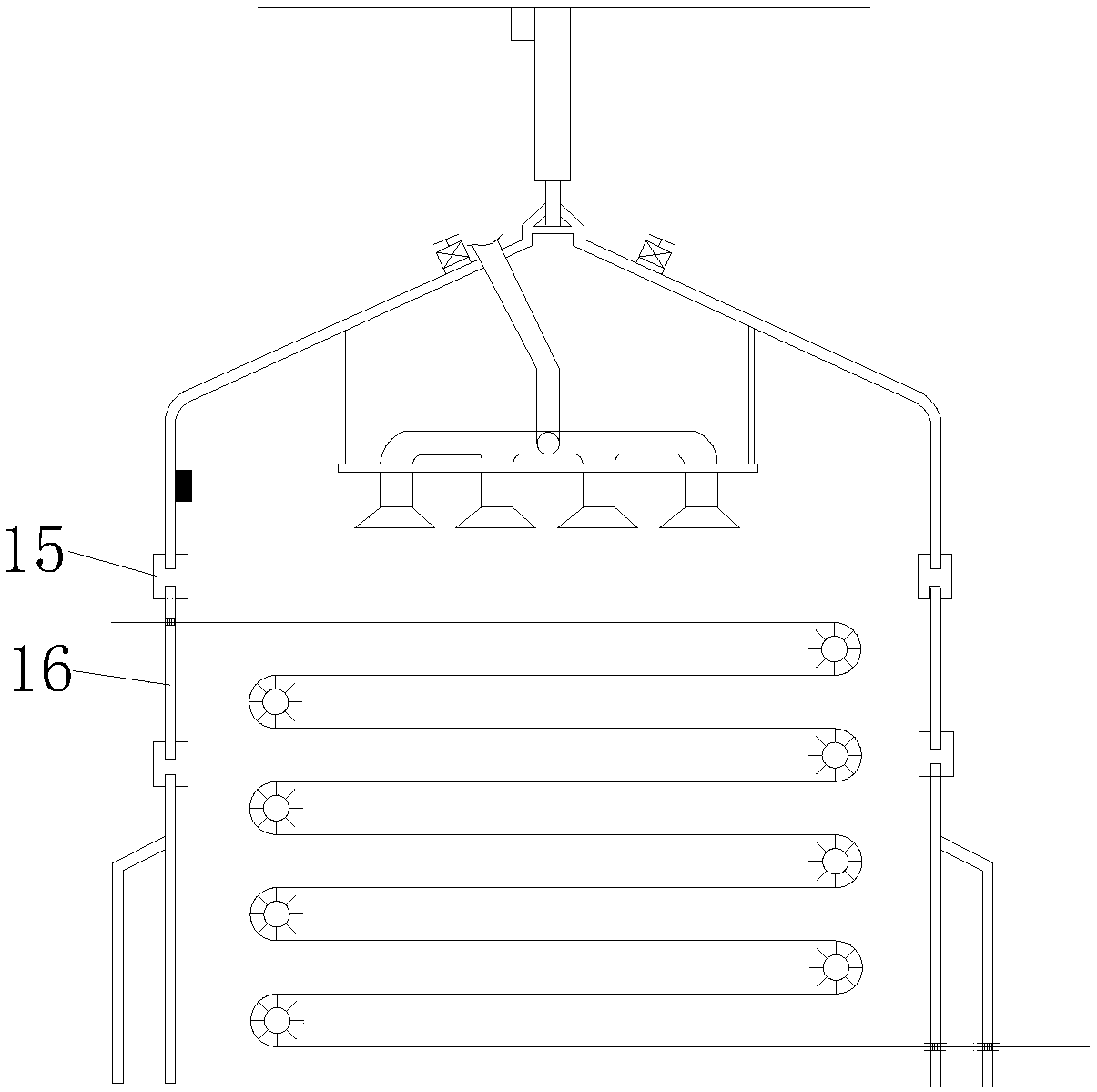

Low-temperature environment-friendly sludge dryer

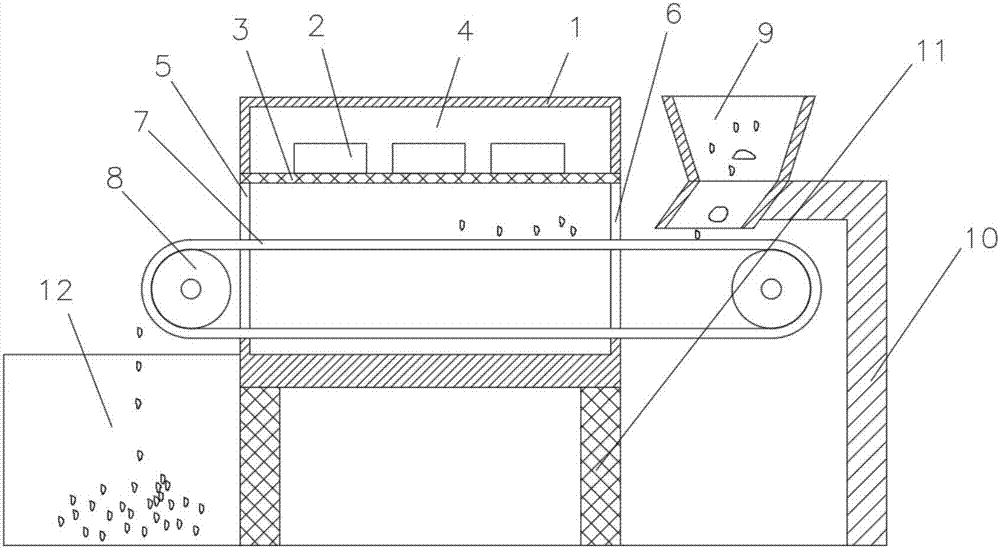

ActiveCN108706851ASimple structureEasy to useSludge treatment by de-watering/drying/thickeningDrying solid materials with heatSludgeConveyor belt

The invention relates to the technical field of sludge processing, in particular to a low-temperature environment-friendly sludge dryer. The low-temperature environment-friendly sludge dryer comprisesa sludge slitting device, wherein a sludge conveying device is arranged on one side of the sludge slitting device, a sludge drying stream line is arranged at one end of the sludge conveying device, asludge drying chamber is arranged on one side of the sludge drying stream line, a sludge drying constant-temperature barrel is arranged on one side of the sludge drying chamber, a sludge drying online monitoring device is arranged on one side of the sludge drying chamber, the sludge drying stream line comprises a shell and a supporting frame arranged in the shell, a plurality of drying conveyor belts are arranged in the supporting frame in a parallel mode, a plurality of side fans are arranged on the outer portion of one side of the drying conveyor belts, and a plurality of top fans are arranged on the top of the drying conveyor belts. The low-temperature environment-friendly sludge dryer is simple in structure, convenient to use and capable of effectively and fully drying sludge, variousparts of the sludge are fully and thoroughly dried, the drying quality is greatly improved, and the sludge drying online monitoring device can facilitate operation of workers.

Owner:广州市浩逸环保科技有限公司

Drying device for redwood furniture processing and drying method thereof

InactiveCN111721092AReduce humidityEasy drying operationDrying solid materials with heatDrying gas arrangementsCircular discHeater Rod

The invention discloses a drying device for redwood furniture processing and a drying method thereof. The drying device comprises a red wood, and further comprises a drying box and a dehumidifying boxwhich are fixed to a base, a sealing cover is installed on the drying box in a clamped mode, an annular heating seat is fixedly installed in the drying box, a plurality of heating rods are installedin the annular heating seat at equal intervals, a plurality of supporting net columns are fixedly installed in the drying box, the red wood is placed on the supporting net columns, and a lifting mechanism is installed between the drying box and the red wood; and a circulating air pump is fixedly installed in the dehumidifying box, a first air pipe is installed at the air inlet end of the circulating air pump, the first air pipe is located in the drying box, a second air pipe is installed at the air outlet end of the circulating air pump, a fan blade and a circular disc are rotatably installedin the dehumidifying box through a rotating shaft, and the circular disc is eccentrically fixed to the rotating shaft. The drying device has the advantages that the high-temperature gas in the dryingbox is dehumidified, meanwhile the flow speed of the high-temperature gas is increased, so as to achieve better and faster drying operation for the red wood.

Owner:贾萍

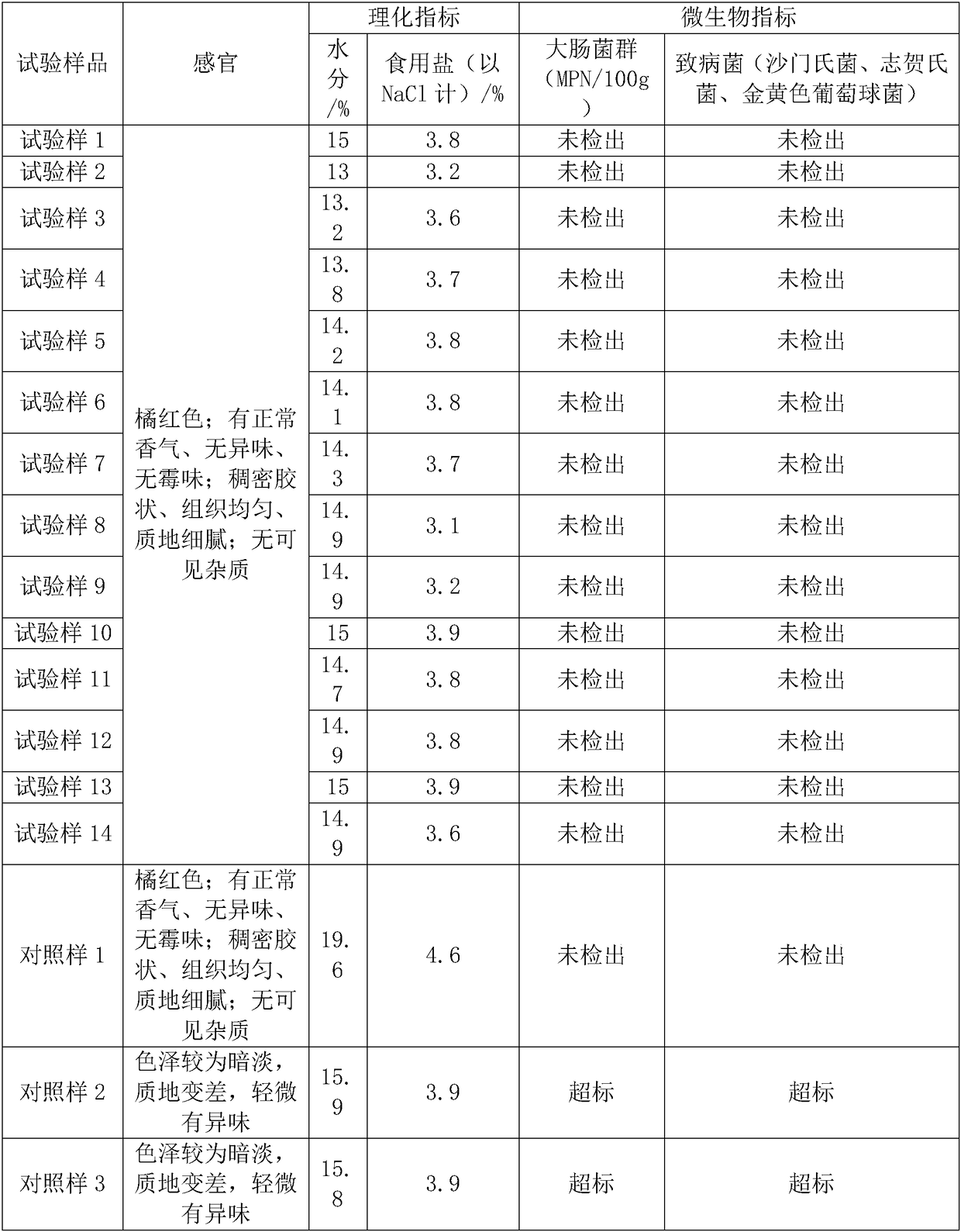

Processing technology of salted egg yolk

The invention discloses a processing technology of salted egg yolk and belongs to the technical field of poultry egg foods. The processing technology includes: 1) selecting pickled salted eggs withoutdamage on shell, deshelling the salted eggs and taking out the whole egg yolk; 2) soaking the salted egg yolk in a sterilization solution for 1-1.5 h, the concentration of NaCl in the sterilization solution being 20-25%; 3) moving the salted egg yolk out from the sterilization solution and drying the salted egg yolk for 2-3 h at 35-45 DEG C; 4) crushing the dried salted egg yolk to form salted egg yolk granules; 5) freeze-drying the salted egg yolk granules at -40 to -50 DEG C for 18-24 h to obtain dried salted egg yolk granules; and 6) vacuum-packaging the dried salted egg yolk granules. Theprocessed salted egg yolk is low in water content and is easy to preserve, and is not liable to deteriorate during transportation.

Owner:HANGZHOU SHUNFENGXIANG FOODS

Intelligent tea drying machine based on internet of things

InactiveCN106720519AQuality assuranceSimple circuit structurePre-extraction tea treatmentElectric machineryDrive motor

The invention relates to an intelligent tea drying machine based on internet of things. The intelligent tea drying machine comprises a drying roller, a discharge hole formed in one end of the drying roller, a fan arranged at the other end of the drying roller, a heating device, and a processing device arranged above the drying roller, wherein the fan is connected with the drying roller by the heating device; the drying roller is provided with a display screen, a switch and a plurality of control buttons. According to the intelligent tea drying machine based on the internet of things, a driving component is driven to rotate by a first drive motor, and blades are driven to rotate by a second drive motor so as to cut and finely separate blocky tea, so that the drying operation of the tea is facilitated, and the quality of the tea is guaranteed; furthermore, the intelligent tea drying machine is simple in structure of working power supply circuit and adopts conventional components and parts, so that the cost of equipment is lowered while stable power output is met, and the market competitiveness of the device is improved.

Owner:南安市瑞欣生物科技有限公司

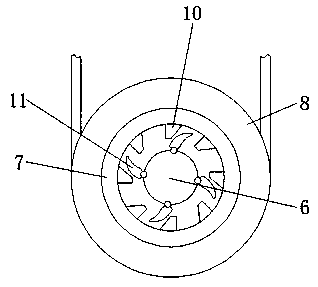

Internet of things based tea drying system

ActiveCN106610174AEasy drying operationPrevent spoilagePre-extraction tea treatmentTea dryingThe InternetAgricultural engineering

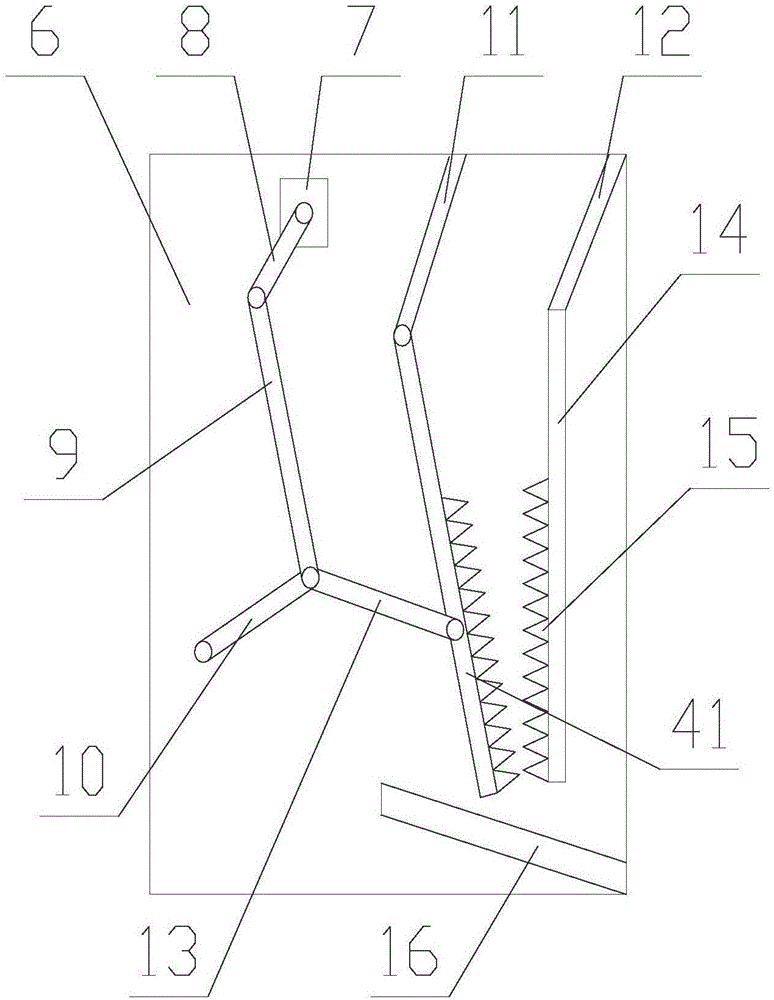

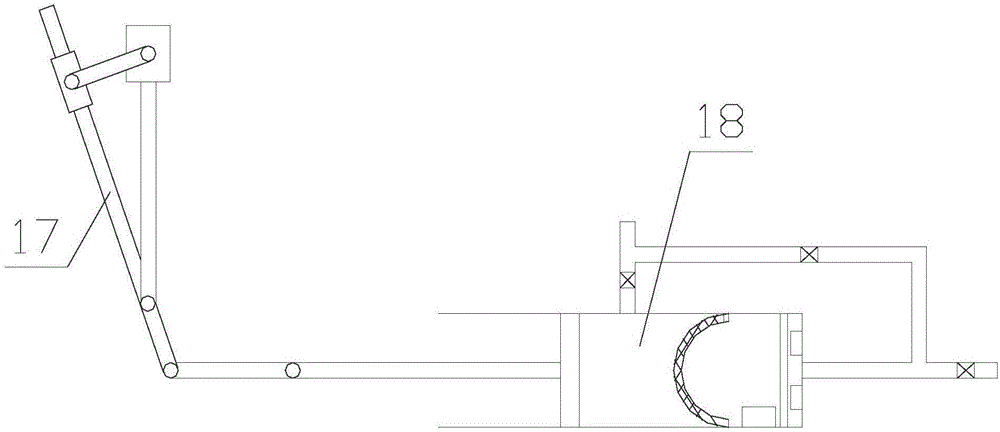

The invention relates to an internet of things based tea drying system, comprising a drying drum, a discharge opening arranged at one end of the drying drum, and a hopper, a processing device and an air guiding mechanism which are arranged at the other end of the drying drum. The hopper is arranged on the processing device, and the processing device and the air guiding mechanism both communicate with the drying drum. According to the internet of things based tea drying system, transmission components drive a second clamping plate to move, so that cakey tea is cut and subdivided by serrations on a first clamping plate and the second clamping plate, so as to facilitate drying operation of the tea; moreover, hot air is imported into the drying drum through air guiding components driven by driving components, and oxygen in the air is consumed while the air is heated by using a hot copper mesh in the air guiding components, so as to prevent the oxygen from oxidizing the tea to cause deterioration during the drying process, thereby further ensuring the quality of dried tea and improving the practicability of the system.

Owner:湖南壶瓶山茶业有限公司

Automatic textile processing drying device

InactiveCN107621156AEasy drying operationReduce secondary wettingDrying gas arrangementsDrying machines with progressive movementsImpellerWater vapor

The invention discloses an automatic textile processing drying device which comprises a workbench. The two sides of the bottom end of the workbench are both fixedly connected with supporting pillars.A drying box is fixedly arranged in the middle of the top end of the workbench. A conveying belt is fixedly arranged inside the drying box. The two ends of the conveying belt are in driving connectionwith driving wheels. A plurality of impellers are arranged at the top end of the inside of the drying box. Through holes are formed in the middle parts of the impellers, and rotating shafts are connected into the through holes in a sleeved mode. According to the automatic textile processing drying device, electric energy can be converted into heat energy through an arranged heating assembly, andhot gas flows into the drying box through a heat conduction pipe so that textiles can be dried; vapor in the drying box can be liquidized through an arranged condensation pipe and then flows into a water collecting tank through a water pipe, and secondary wetting to the textiles by the vapor is reduced; and meanwhile the water collecting tank can be used for collecting water, waste of resources isreduced, the whole drying device can be controlled through an arranged control box, automation is realized, manual operation is replaced and drying efficiency is improved.

Owner:湖州创一装饰设计工程有限公司

Method for testing porosity of green plate

PendingCN113758824AShort test timeEasy to operateWeighing by removing componentPermeability/surface area analysisPhysicsMineralogy

The invention relates to the field of porosity testing, and provides a method for testing the porosity of a green plate, aiming at the problem that the test result of the porosity of the green plate is inaccurate. The method comprises the following steps of: numbering and weighing one green plate, and recording the weight as dry weight M11; measuring the length L11, the width S11 and the thickness H11 of the green plate; performing ethanol permeation on the green plate, taking out the green plate, and weighing the green plate as a wet weight M12; then removing active substances on the polar plate, drying and weighing the mass of the grid, and recording the mass as M13, wherein the porosity A11 of the first green plate is equal to (M12-M11) / rho ethanol / (L11 * S11 * H11-M13 / rho grid) * 100%; and finally, taking a plurality of green plates at the same position in parallel, repeating the previous steps to measure a plurality of porosities, and taking an average value as the porosity of the position. The process method is simple, the test is convenient and fast, and the measured porosity of the green plate is high in accuracy.

Owner:CHAOWEI POWER CO LTD +1

Rapid water removal device for transformer oil

InactiveCN108251151AFast water removal rateReduce the watering timeVacuum distillationPower flowReciprocating motion

The invention relates to a rapid water removal device for transformer oil. The characteristic that water is boiled and evaporated into gas due to the fact that the boiling point is reduced under ultralow air pressure is utilized, the old transformer immersion oil is vacuumized to be 0.01MPa and heated to 60-80 DEG C, so that the water can be rapidly evaporated, and therefore the drying operation of the old transformer immersion oil is completed according to the invention; the water removal and drying operation can be completed at one time, a pulse relay is used for controlling the on-off of the coil current in the electromagnet, so that a non-magnetic spring, a transverse rod and an iron block are allowed to do up-and-down reciprocating motion, and therefore liquid inside an electric heating tank body can be continuously stirred, so that the water outlet time is remarkably shortened, and the whole water removal process does not exceed 10 minutes, the water removal rate is high, and a drying agent does not need to be replaced, so that the drying operation is simple and convenient.

Owner:TONGLING RIKE ELECTRONICS

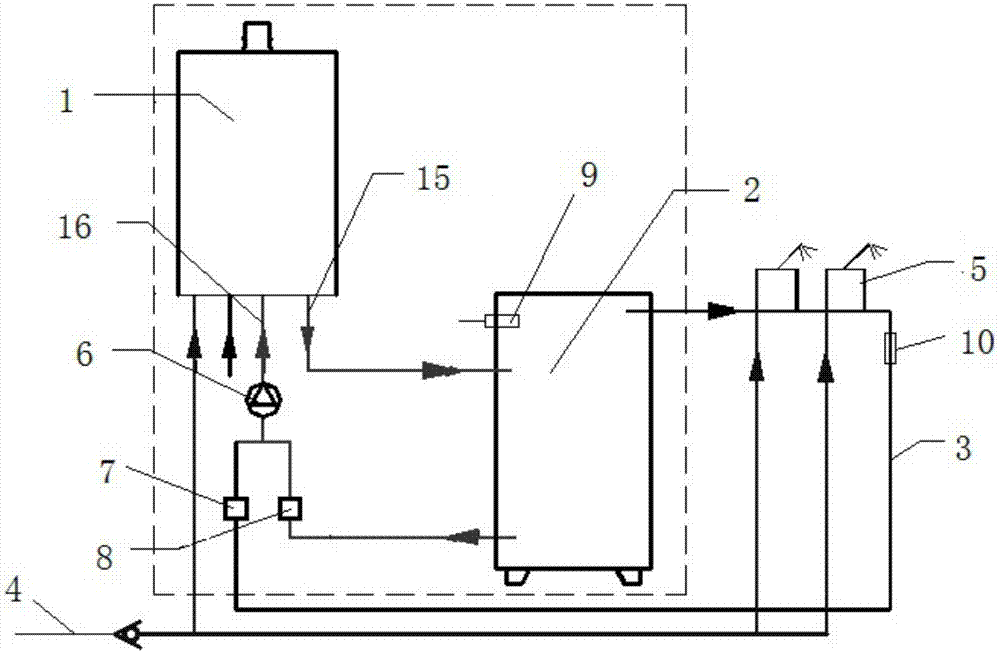

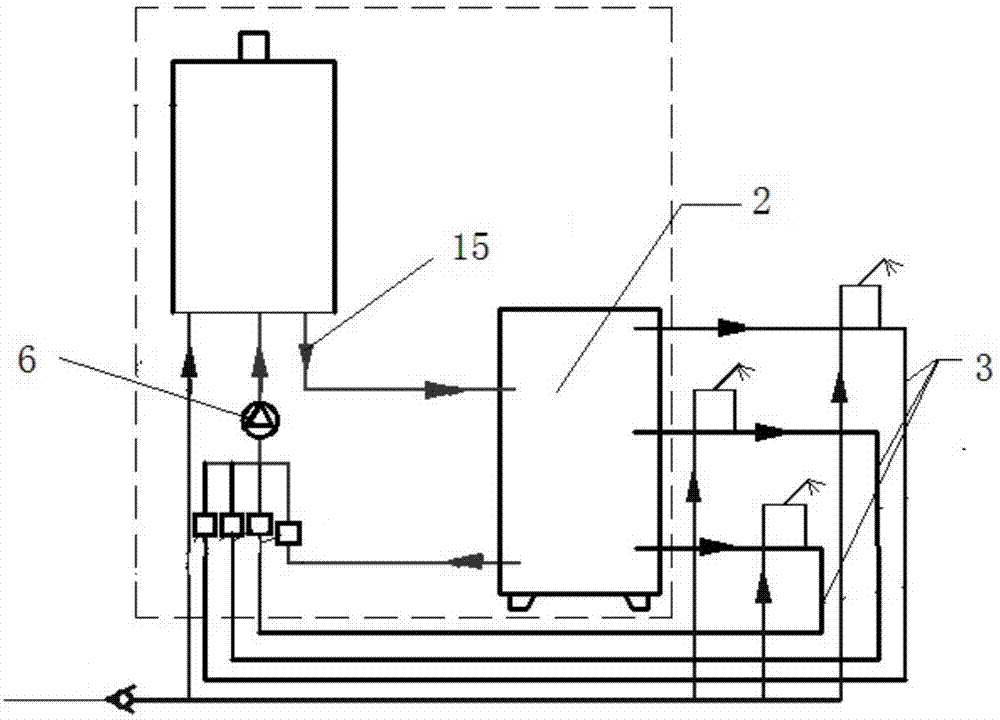

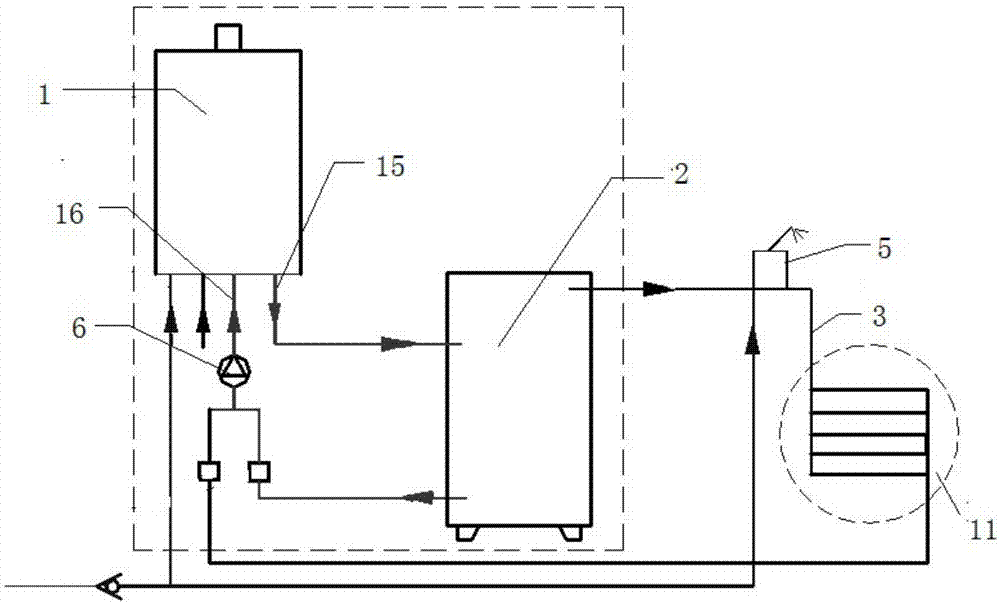

Central hot water circulating system

PendingCN107314531ASolve the problem of using hot water at the same timeAchieve instant heatMechanical apparatusWater heatersEngineering

The invention discloses a central hot water circulating system which comprises a gas water heater, a water storage tank, a water-using pipeline and a cold water inlet pipe. Water of the water storage tank is only supplied by the gas water heater, and the water of the water-using pipeline is supplied by the water storage tank; water-using points are arranged on the water-using pipeline, and the cold water inlet pipe supplies cold water to the gas water heater and the water-using points; and the central hot water circulating system is characterized in that a first circulating loop is form by the water outlet end of the gas water heater, the water storage tank, the water inlet end of the gas water heater, and the a second circulating loop is form by the water outlet end of the gas water heater, the water storage tank, the water-using pipeline and the water inlet end of the gas water heater. According to the central hot water circulating system, the two circulating loops are arranged, so that a large amount of hot water is kept in the water storage tank all the time, the effect that the hot water is simultaneously used by a plurality of hot water points can be achieved, and the effect that the water is instantly heated the moment all the external water-using points are opened can also be achieved.

Owner:GUANGDONG MACRO GAS APPLIANCE

Energy-saving intelligent drying equipment for textile fabric

InactiveCN112179104ASmooth transmissionEasy drying operationDrying gas arrangementsDrying chambers/containersElectric machineryStructural engineering

The invention discloses energy-saving intelligent drying equipment for a textile fabric and belongs to the field of textile fabric drying. The energy-saving intelligent drying equipment comprises a drying box, wherein a rectangular groove is formed in the left side of the drying box, a first fixed plate is fixedly connected to the lower end in the drying box, a conveyor belt is arranged on the topof the fixed plate, transmission wheels are rotatably connected to two ends of the conveyor belt, and a forward and backward motor is mounted below the first fixed plate. By arranging a hot-air blower, a transmission pipeline, a connecting pipe and a spray head, the textile fabric on the conveyor belt can be dried. By arranging a transmission fan, an air suction pipe, an air outlet channel, an air outlet pipe, a rolling box and a wind-up roll, the transmission fan can absorb hot air from the air outlet channel through the air suction pipe and transmit the hot air to the air outlet pipe to drythe rolling box internally so as to dry two sides of the fabric on the wind-up roll fully, so that the textile fabric is dried more uniformly.

Owner:绍兴市华获智能装备有限公司

White sesame seed and needle mushroom cookies with effects of benefiting liver and nourishing hair and preparation method thereof

InactiveCN106417535AShorten face-to-face timeImproves touch and glossDough treatmentBakery productsPeppermintsFlavor

The invention discloses white sesame seed and needle mushroom cookies with the effects of benefiting the liver and nourishing hair. The cookies are prepared from, by weight, 300-320 parts of low-gluten flour, 120-130 parts of fresh needle mushrooms, 6-7 parts of olive oil, 20-23 parts of white sesame seeds, 9-10 parts of peppermint candy, 14-16 parts of water chestnuts, 65-70 parts of butter, 90-95 parts of white granulated sugar, 4-4.5 parts of salt and a proper amount of citric acid, sodium isoascorbate, sodium pyrosulfite, sodium carboxymethylcellulose, soya bean lecithin and water. The needle mushroom cookies have rich raw materials, the main material is reasonably matched with multiple auxiliary materials such as the olive oil and the white sesame seeds, and the prepared finished cookies are higher in nutritional value. In the processing process, the needle mushrooms are subjected to color protection, the needle mushrooms are evenly dried gradually, and the certain stability and special flavor of the needle mushrooms are kept; the cookies have the effects of benefiting the liver and nourishing hair after being eaten, and are suitable for a wide range of people.

Owner:钱毅

Pipeline type normal temperature dryer for walnut

InactiveCN1948875AReduce power consumptionNo pollution in the processDrying solid materials with heatDrying machines with local agitationWalnut NutLitter

The invention supplies walnut pipeline type normal temperature dryer. It ties plastic film pipe at the output of the normal temperature fan, fills the walnut into the pipe, ties the output of the film pipe at hard outlet pipe, inserts stirring stick between the film pipe and the ground. The invention has the advantages of low investment, simple operation, easy controlling, litter powder expenditure, better flavor for dried walnut than heat drying.

Owner:SICHUAN UNIV

Yoghourt and needle mushroom biscuit for enhancing immunity and preparation method thereof

InactiveCN106359496APlay an emulsifying roleReduce cholesterolDough treatmentBakery productsFlavorGluten

The invention discloses a yoghourt and needle mushroom biscuit for enhancing immunity. The yoghourt and needle mushroom biscuit is prepared from the following materials in parts by weight: 300-320 parts of low-gluten flour, 120-130 parts of fresh needle mushroom, 18-20 parts of buckwheat sprout, 16-19 parts of yoghourt, 26-30 parts of pine nut, 3-4 parts of cattail root, 65-70 butter, 90-95 parts of white granulated sugar, 4-4.5 parts of salt, citric acid, sodium isoascorbate, sodium pyrosulfite, sodium carboxymethylcellulose, soya bean lecithin, and a proper amount of water. The needle mushroom biscuit has rich materials, the main material is reasonably matched and processed with multiple auxiliary materials like yoghourt and pine nut, the prepared finished product of biscuit is rich in nutrient, the color of the needle mushroom is protected in the processing process, the needle mushroom is evenly dried gradually, certain stability and the special flavor of the needle mushroom are kept, and if taken for a long period of time, the needle mushroom biscuit has the effects of life cultivation and health preservation, and plays a role of enhancing immunity.

Owner:胡王振

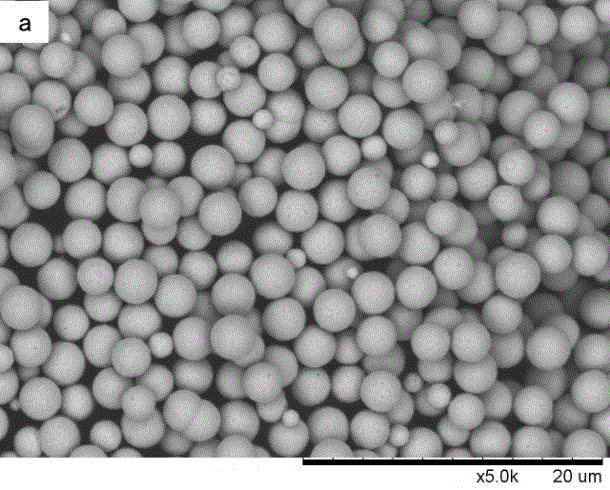

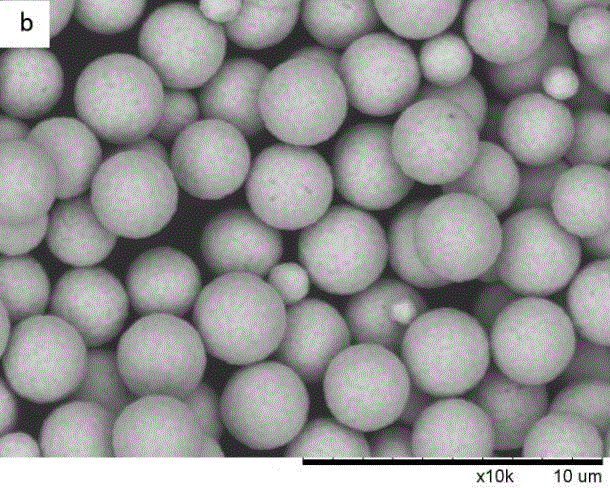

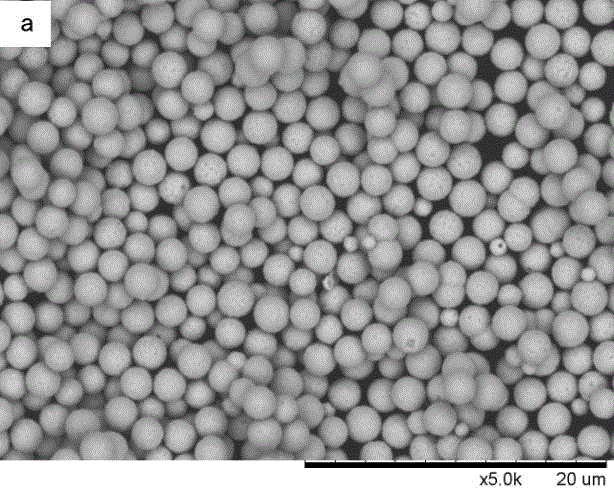

Preparation method for monodisperse spherical silver powder

InactiveCN106001603AGood dispersionEasy to cleanTransportation and packagingMetal-working apparatusPotassium hydrogen phthalateAqueous solution

The invention discloses a preparation method for monodisperse spherical silver powder. The preparation method comprises the following steps: mixing a silver nitrate solution with a reducing agent solution to obtain a mixed solution; standing the mixed solution; filtering the mixed solution; cleaning the mixed solution; and drying the mixed solution. The reducing agent solution is an acidic aqueous solution of ascorbic acid; the reducing agent solution is added with chitosan and potassium hydrogen phthalate which are used as a dispersing agent, sulfuric acid which is used as a nodulizing agent and nitric acid which is used as an acid regulator. Compared with the prior art, the preparation method has the beneficial effects that: the preparation method for the monodisperse spherical silver powder is simple to operate; obtained silver powder is in a monodisperse state; silver powder particles are regularly spherical; liquidity is good; impurity content is low; and the preparation method is especially suitable for being used in the field of electronic paste.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Food dehydration equipment

The invention discloses food dehydration equipment. The food dehydration equipment includes a control device, a drying box and a heating device. The drying box includes a box body with a box door, thebox body is internally provided with several layers of material placement partitions arranged up and down, trays for containing materials are arranged on the material placement partitions, the bottomof one side face of the box body is provided with an air inlet, the top of the other side face of the box body is provided with an air outlet, the two side faces are opposite to each other, the innerside face, provided with the air inlet, of the box body is fixedly provided with an air distribution pipe, the heating device includes a hot air device and a microwave device, the hot air device is connected with the air distribution pipe, the microwave device includes a magnetron and a number of waveguide tubes connected with the magnetron, and the waveguide tubes are uniformly arranged on the inner face of one side of the box body. According to the food dehydration equipment, the drying time is short, the temperature is controllable, the stress on the surface and inside of a food is uniformin the drying process, and the taste is good.

Owner:合肥市福客多快餐食品有限公司

Automatic impurity removal and preservation device applied to bagasse recycling

ActiveCN111282630AEfficient drying operationEfficient crushing operationsGrain treatmentsInterior spaceDrive shaft

The invention discloses an automatic impurity removal and preservation device applied to bagasse recycling. The automatic impurity removal and preservation device includes an equipment box body, a feed inlet and a discharge port are correspondingly installed on the edge sides of the top end and bottom end of the equipment box body, a second filter screen is installed on the left side of the internal space of the equipment box body and located below a crushing block, the upper end surface of the crushing block is fixedly connected with a vertically distributed vertical shaft, a horizontally distributed fixing plate is arranged above the crushing block, the center of the fixing plate is rotatably connected with the vertical shaft, a drive shaft is arranged below the fixing plate, and a horizontally distributed horizontal shaft is arranged below the second filter screen. According to the automatic impurity removal and preservation device applied to bagasse recycling, through the redesignof the internal structure of the device, the whole device is enabled to not only use bagasse transportation as a power source for the efficient drying operation of bagasse, but also perform efficientcrushing processing operation on the bagasse, thereby ensuring the effect of removing impurities and facilitating subsequent preservation and recycling.

Owner:ZHANJIANG EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

Mobile filter cloth drying device

InactiveCN108592587AGuaranteed to be fully enclosedFree from pollutionDrying chambers/containersDrying machines with progressive movementsEngineeringMechanical engineering

The invention discloses a mobile filter cloth drying device, comprising a cover shell body, an electric sliding frame and at least two electrically controlled rollers. A heating device is arranged onthe inner wall of the cover shell body. The electric sliding frame is arranged above the cover shell body and connected with the top of the cover shell body through a first lifting unit. A filter cloth inlet and a filter cloth outlet are separately formed in the two end faces opposite to each other of the cover shell body, the filter cloth inlet and the filter cloth outlet are horizontally disposed, and the width of the filter cloth inlet and the width of the filter cloth outlet adapt to the width of a filter cloth. The filter cloth enters the inside of the cover shell body through the filtercloth inlet, and is output out of the cover shell body through the filter cloth outlet. All the electrically controlled rollers are parallel to the filter cloth inlet and are uniformly distributed andarranged at the two ends corresponding to the filter cloth inlet and the filter cloth outlet in the cover shell body, and the two ends of each electrically controlled roller are separately connectedwith the inner wall of the cover shell body. According to the mobile filter cloth drying device, the filter cloth in different working position is subjected to drying, the drying process is completelysealed, and poisonous and pernicious gas is avoided to leak.

Owner:JIANGSU LINGFULONG ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com