Processing technology of salted egg yolk

A processing technology and salted egg yolk technology, applied in the field of salted egg yolk processing technology, can solve the problems of high packing box density and deterioration, and achieve the effects of being less prone to deterioration, prolonging the shelf life and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

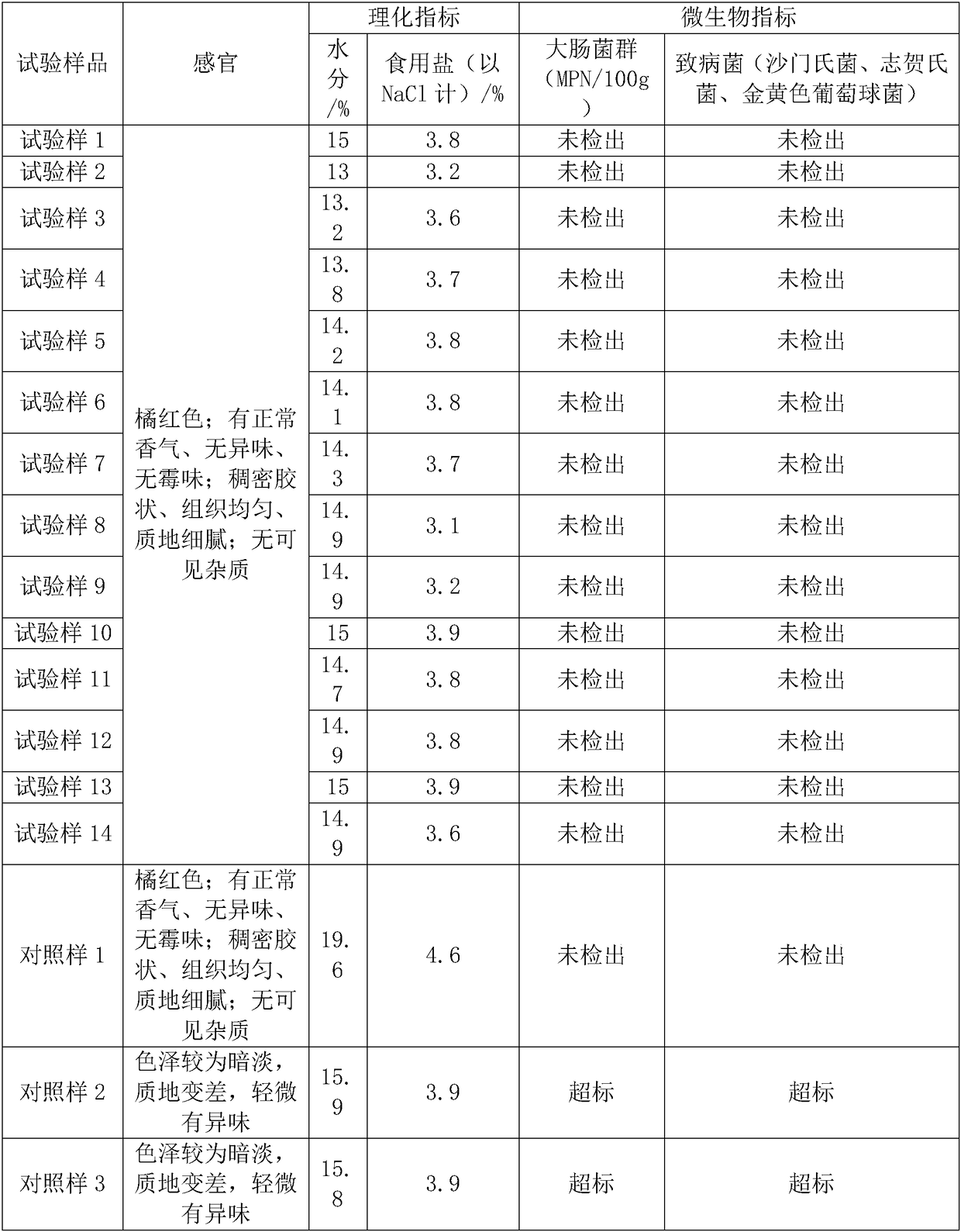

Examples

Embodiment 1

[0052] Embodiment 1: a kind of processing technology of salted egg yolk, obtains by following steps:

[0053] Step 1, select the salted egg after pickling and the eggshell is not damaged, remove the shell and take out the whole salted egg yolk, and keep the egg yolk membrane outside the salted egg yolk intact and not broken;

[0054] In step 2, the salted egg yolk obtained in step 1 is placed in a bactericidal solution with a sodium chloride concentration of 25%, and immersed for 1 hour;

[0055] Step 3, take out the salted egg yolk from the bactericidal solution in Step 2, and place it in a 35°C environment to dry for 3 hours;

[0056] Step 4, the dried salted egg yolk in step 3 is crushed to form salted egg yolk particles with a size of 3 mm;

[0057] In step 5, the salted egg yolk particles obtained in step 4 are freeze-dried in an environment of -40° C. for 24 hours to obtain dry salted egg yolk particles;

[0058] Step 6, vacuum-packing the dried salted egg yolk particl...

Embodiment 2

[0066] Embodiment 2: a processing technique of salted egg yolk, the difference from Example 1 is that in the step 5 of processing the salted egg yolk, the dried salted egg yolk particles obtained in the step 4 are first subjected to low-temperature vacuum dehydration drying treatment, and the low-temperature vacuum dehydration is carried out. The drying treatment is carried out under the vacuum degree of 80-110kpa, the temperature of the cold trap is set to drop to -40~-50°C at a cooling rate of 0.5°C / min, the treatment time is 5-8h, and then vacuum packaging is performed.

Embodiment 3

[0067] Embodiment 3: a processing technique of salted egg yolk, the difference from Example 1 is that in the step 5 of processing the salted egg yolk, the dried salted egg yolk particles obtained in the step 4 are first subjected to low-temperature vacuum dehydration drying treatment, and the low-temperature vacuum dehydration is carried out. The drying treatment is carried out under the vacuum degree of 80-110kpa, the temperature of the cold trap is set to drop to -40~-50°C at a cooling rate of 0.5°C / min, the treatment time is 5-8h, and then vacuum packaging is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com