Novel process for production of fragrant rice processing

A new process, fragrant rice technology, applied in application, preservation of seeds by drying, grain processing, etc., can solve problems such as difficulty in meeting different tastes, inconvenient drying operation, and insufficient shelf life of packaging, and reduce the quality of broken rice. Proportion, conducive to drying and ventilation, and the effect of long-term preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

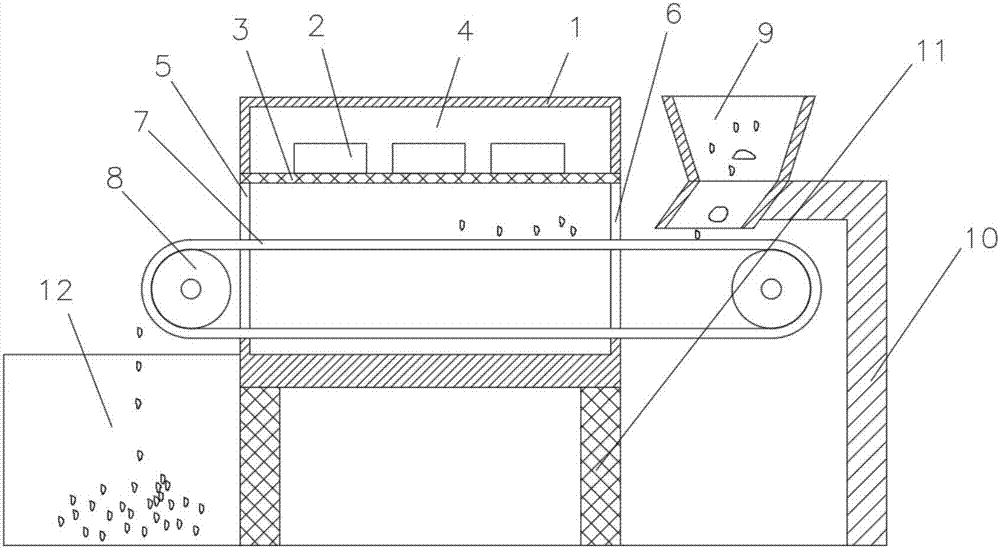

[0029] Example 1, such as figure 1 Shown:

[0030] A new production process for fragrant rice processing, comprising the steps of:

[0031] (1) Paddy drying treatment: the fragrant rice paddy harvested is placed in drying box 1 and dried, and described drying box 1 left side is provided with outlet 5, and right side is provided with entrance 6; The interior of drying box 1 is provided with partition 3. The partition 3 separates an inner cavity 4 from the upper part of the drying box 1, and a number of hot air blowers 2 are arranged in the inner cavity 4; a plurality of through-hole structures are arranged on the partition 3, so that the hot air can pass through The holes output the hot air to dry the paddy; the drying box 1 is provided with a conveyor belt 7, and the two ends of the conveyor belt 7 are matched with a transmission wheel 8 inside; the conveyor belt 7 passes through the drying box 1 through the inlet 6 and the outlet 5 Installation; the upper right end of the c...

Embodiment 2

[0042] As a preference of this scheme, the shape of the drying box 1 is a box with a cuboid structure; the bottom of the box is symmetrically provided with a chassis 11 for supporting the drying box 1 on both sides; the feed hopper 9 passes through the bracket 10 for installation, the feed hopper 9 is positioned directly above the right end of the conveyor belt 7, and the lower end opening of the feed hopper 9 is inclined toward the direction of the inlet 6, and the material of the feed hopper 9 is a stainless steel material; The number is 2 or more; the bottom of the hot air blower 2 is installed on the upper surface of the partition 3 . Preferably, the material of the conveyor belt 7 is an elastic insulating rubber material, the trough 12 below the left end of the conveyor belt 7 is a square groove structure, the material of the trough 12 is stainless steel, and the opening width of the trough 12 is greater than the width of the conveyor belt 7 size.

[0043] Through the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com