Pipeline type normal temperature dryer for walnut

A room-temperature drying and pipeline-type technology, which is applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve problems such as intolerance to storage, carcinogenicity, and deterioration of walnut flavor, and achieve excellent quality and flavor. The effect of easy drying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

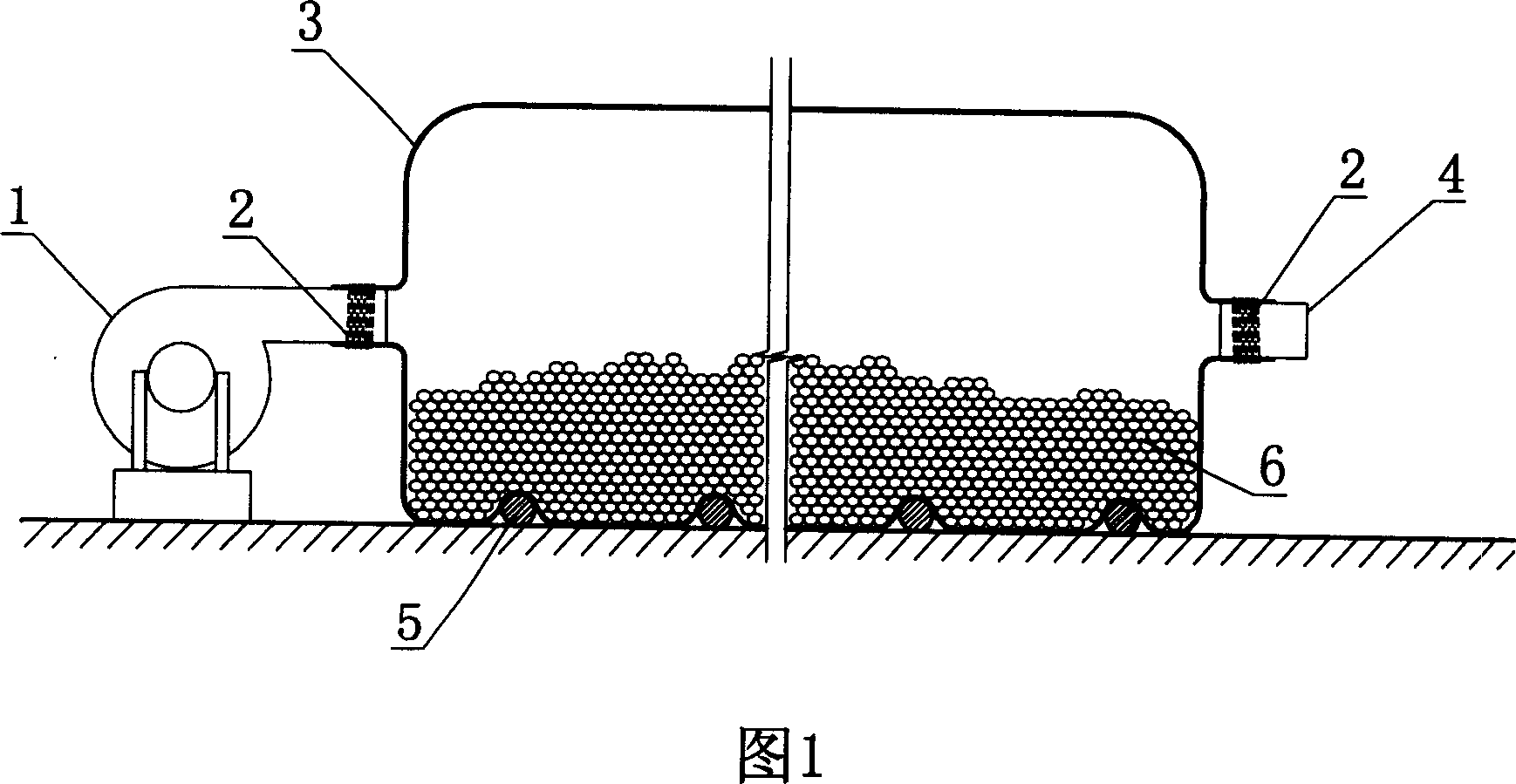

[0017] The walnut (6) to be dried is packed into diameter 1.0m, and thickness is 0.1mm, the polyethylene film tube (3) of length 20m, and loading is 1 / 3 of film tube cross-sectional area under the inflation state, and film The inlet of the pipe is tied on the outlet of the blower fan (1) with a binding rope (2), and the outlet of the film pipe is tied on a hard outlet pipe (4) with a length of 30 cm and an inner diameter of 1 / 5 of the diameter of the film pipe. The power is 0.4KW, and the walnut (6) is turned once every 6 hours after starting up. The method of turning is to use a turning stick (5) with a length of 1.5m and a diameter of 4cm, and one end becomes a smooth spherical surface, and the spherical end of the stick is removed from the film tube. Penetrate horizontally between the ground, the midpoint of the rod is at the centerline of the film tube, and the distance between the rods is 1m. When turning, the outer end of the rod is lifted off the ground at an angle of 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com