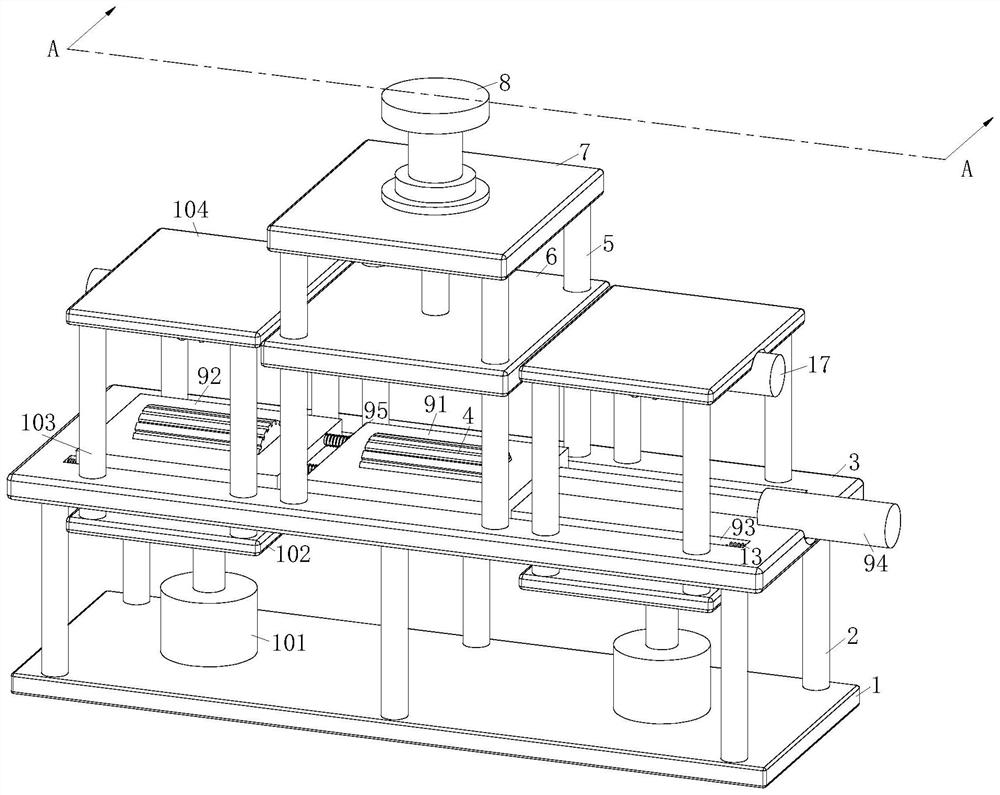

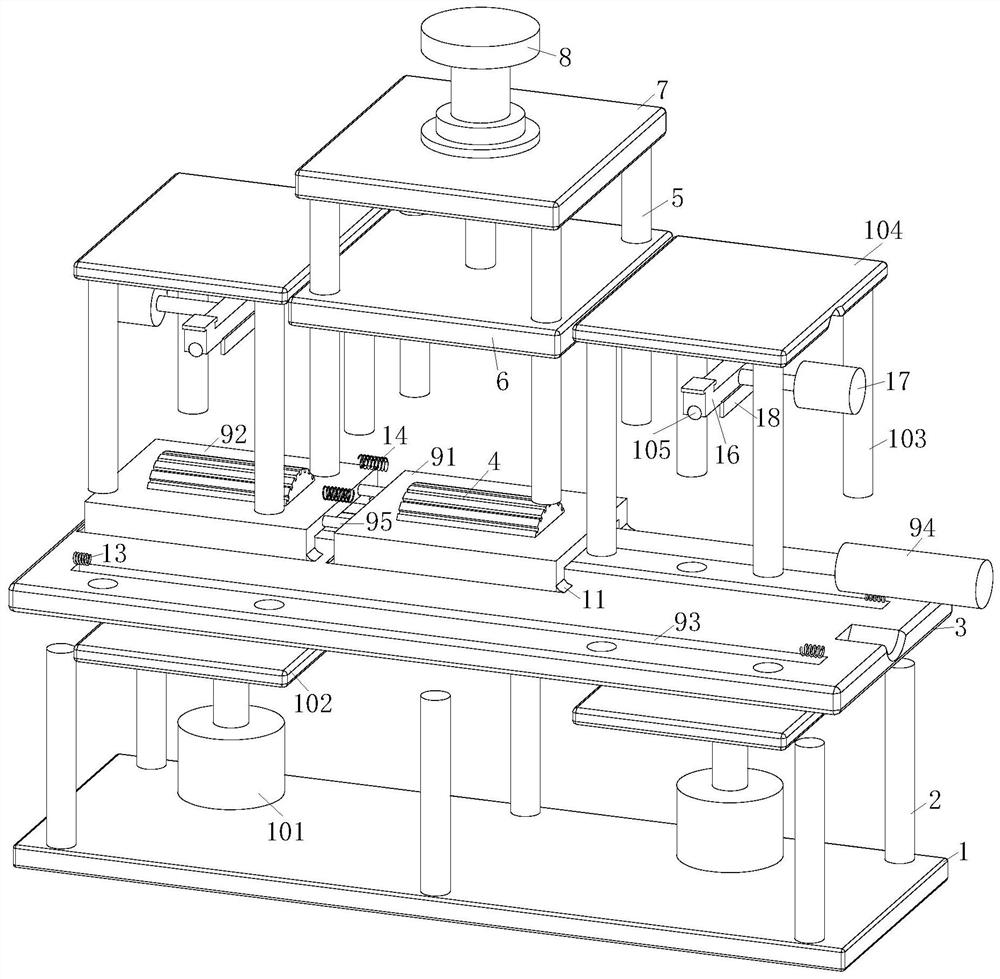

Lost-foam casting forming machine

A technology of moldless casting and forming machine, which is applied in the direction of casting and forming equipment, etc., to achieve the effect of prolonging working time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

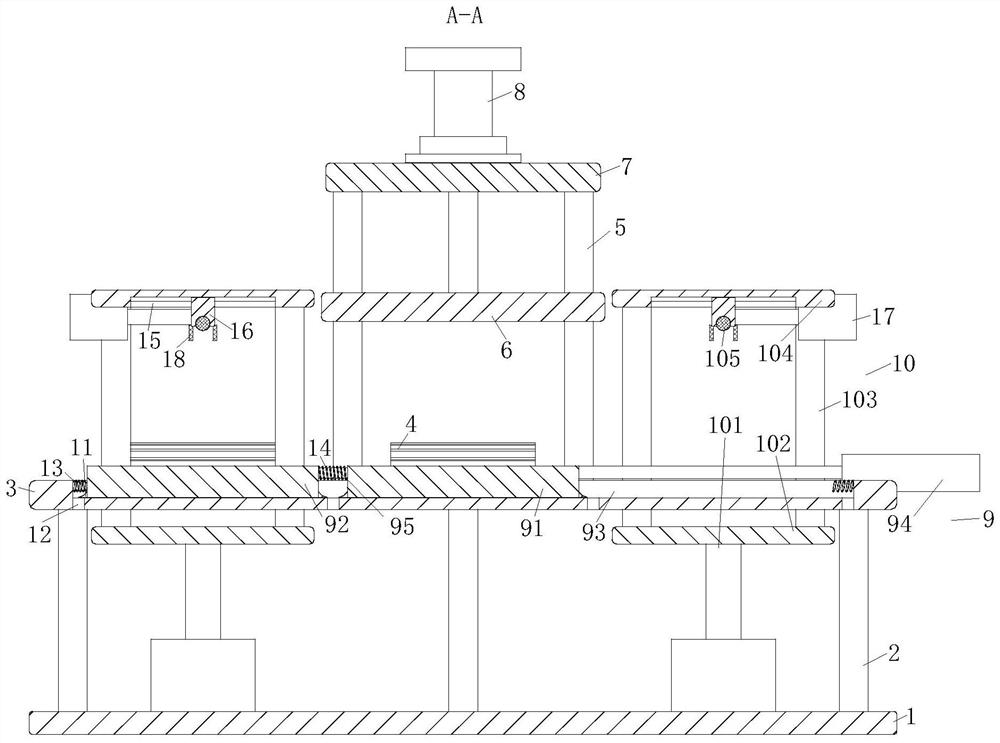

Method used

Image

Examples

Embodiment approach

[0029] As an embodiment of the present invention, a scraper 11 is provided at the two ends of the No. 1 sliding plate 91 and the No. 2 sliding plate 92 at the positions corresponding to the No. 1 chute 93; There are four groups of ash leakage ports 12; wherein the two groups of ash leakage ports 12 are respectively located at the two ends of No. 1 chute 93; during work, the present invention is provided with scraper 11 and ash leakage port 12; when No. 1 When the electric push rod 94 drives the No. 1 sliding plate 91 and the No. 2 sliding plate 92 to move back and forth along the No. 1 chute 93, the scrapers 11 at both ends of the No. 1 sliding plate 91 and the No. The dust and impurities in the groove 93 are removed into the ash leakage port 12 and discharged through the ash leakage port 12, so that the impurities in the No. 1 chute 93 will not affect the moving process of the No. 1 sliding plate 91 and the No. 2 sliding plate 92, which improves the The working effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com