Automatic round steel cutting device

A technology of cutting device and round steel, which is applied to shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve the problems of high labor cost and inability to adjust the cutting angle easily and quickly, and save labor costs and convenience. Quick cutting angle, convenient and quick adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] The servo motor 3 mentioned in the present invention (the model is 57HS22) can be purchased from the market or obtained by private customization.

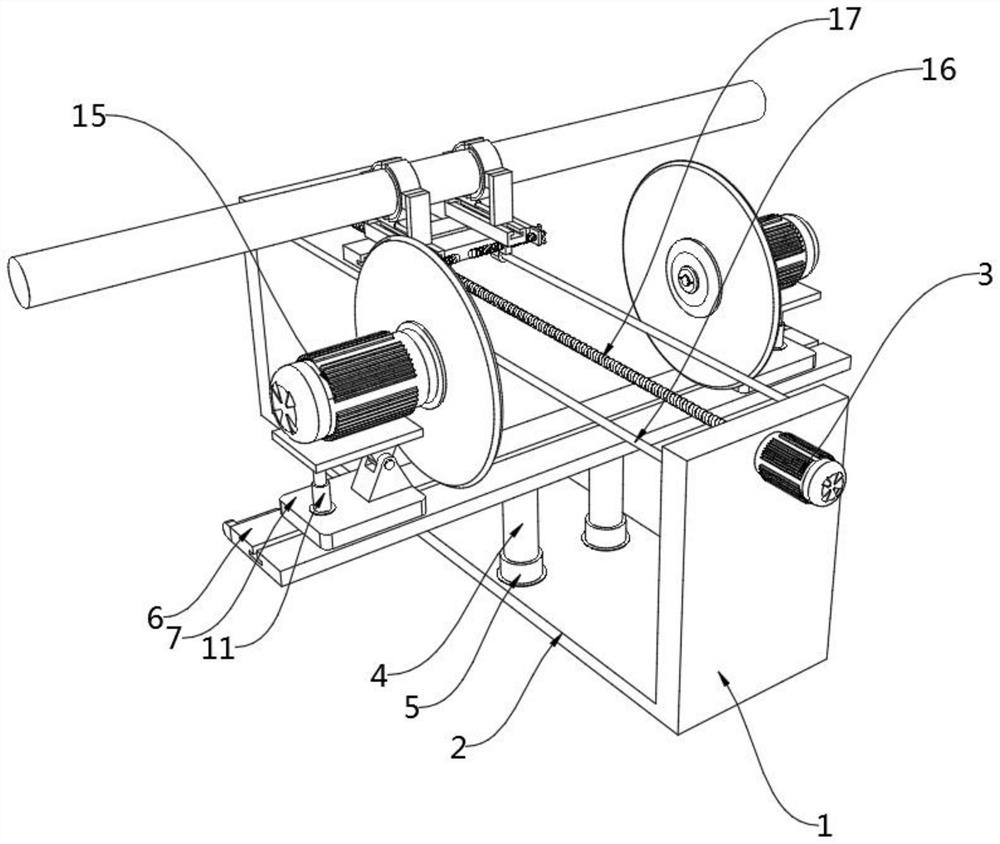

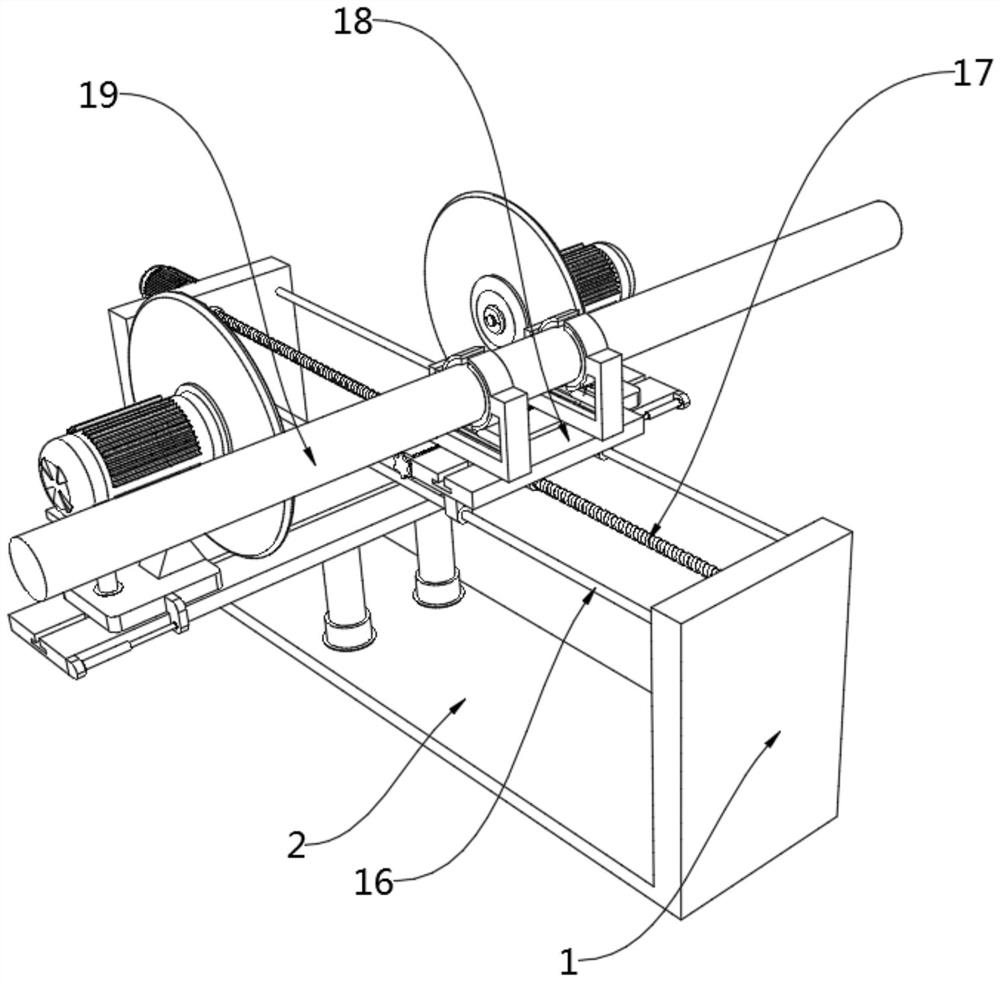

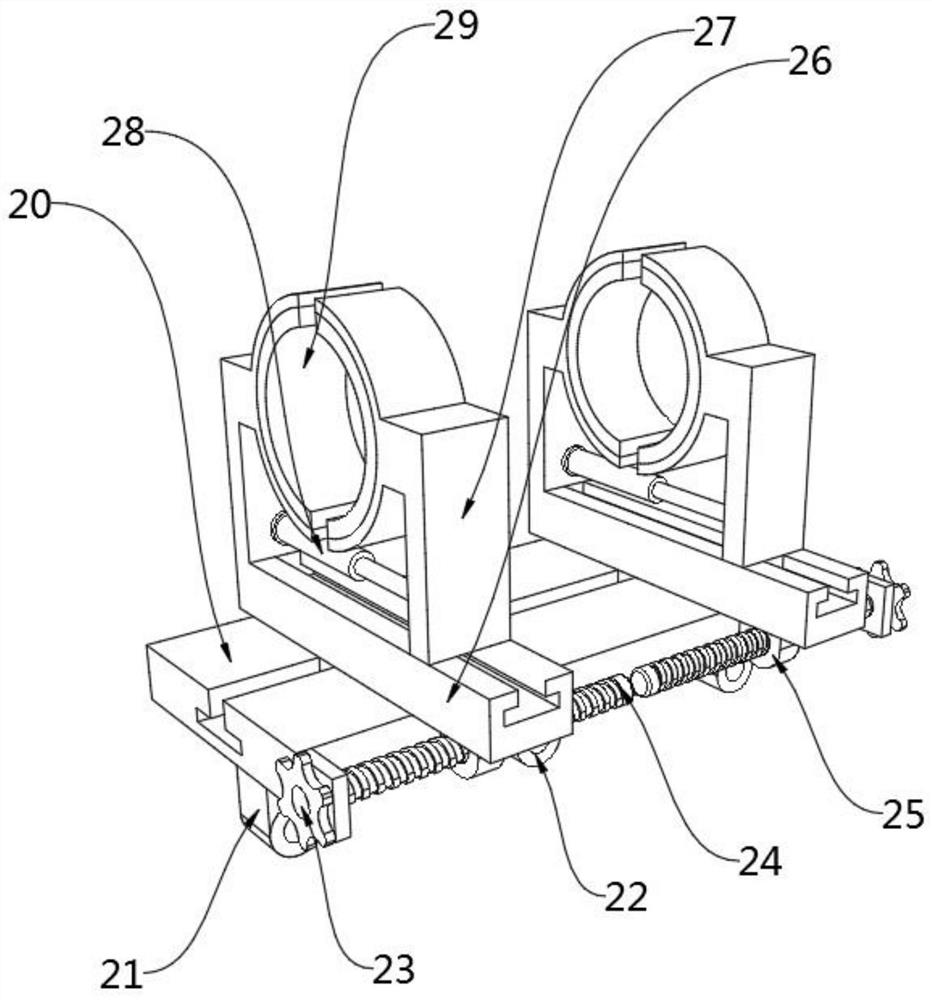

[0024] see Figure 1 to Figure 5 , an embodiment provided by the present invention: an automatic round steel cutting device, including a base plate 2, side plates 1 are installed on both sides of the base plate 2, a servo motor 3 is installed on one side of one side plate 1, the base plate 2 Two shock absorbers 5 are installed on the upper surface of the shock absorber 5, a connecting leg 4 is installed on the upper end of the shock absorber 5, a supporting plate 6 is installed on the upper end of the connecting le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com