Laser processing apparatus and method for adjusting laser processing apparatus

A technology of laser processing and laser beams, applied in auxiliary devices, metal processing, laser welding equipment, etc., can solve the problems of cost, expensive wave surface sensors, and labor hours for replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The present invention is not limited to the contents described in the following embodiments. In addition, the constituent elements described below include substantially the same constituent elements that can be easily conceived by those skilled in the art. In addition, the structures described below can be combined appropriately. In addition, various omissions, substitutions, or changes in the configuration can be made without departing from the spirit of the present invention.

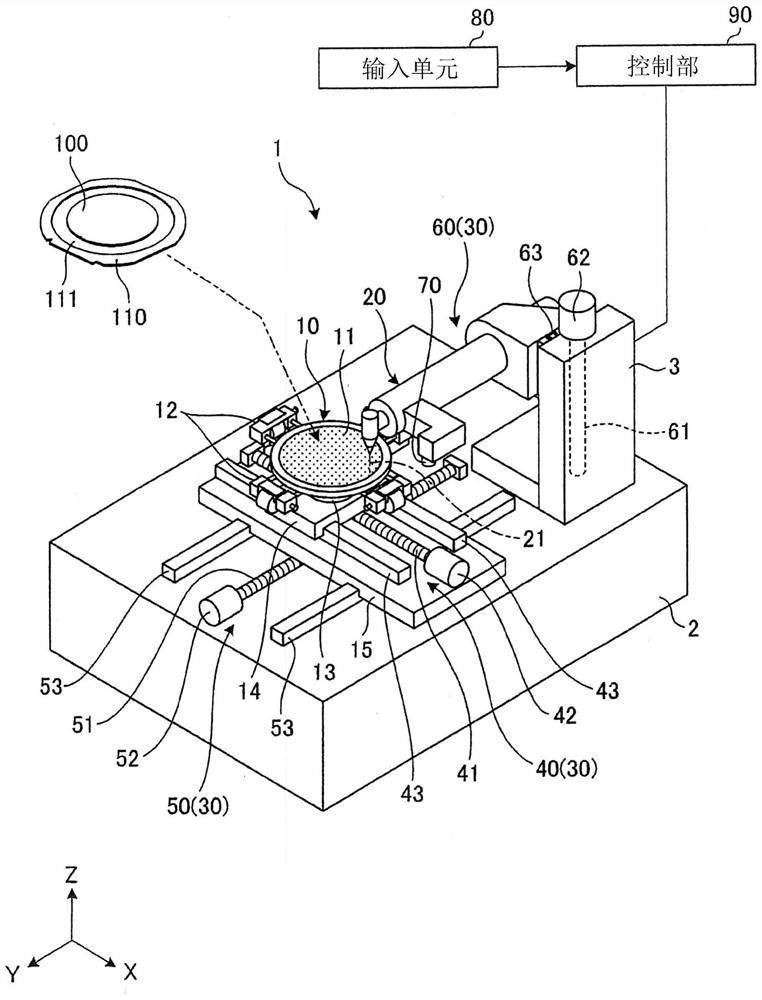

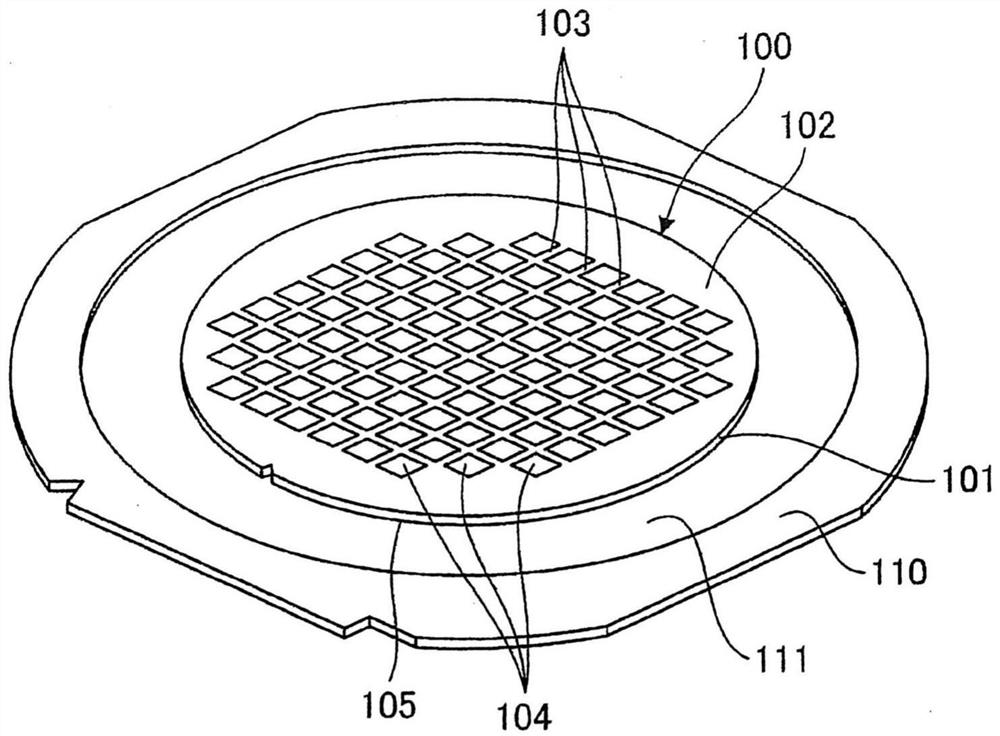

[0026] The laser processing apparatus 1 which concerns on embodiment of this invention is demonstrated based on drawing. figure 1 It is a perspective view which shows the structural example of the laser processing apparatus 1 of embodiment. figure 2 is as figure 1 A perspective view of a workpiece 100 to be processed by the laser processing apparatus 1 shown.

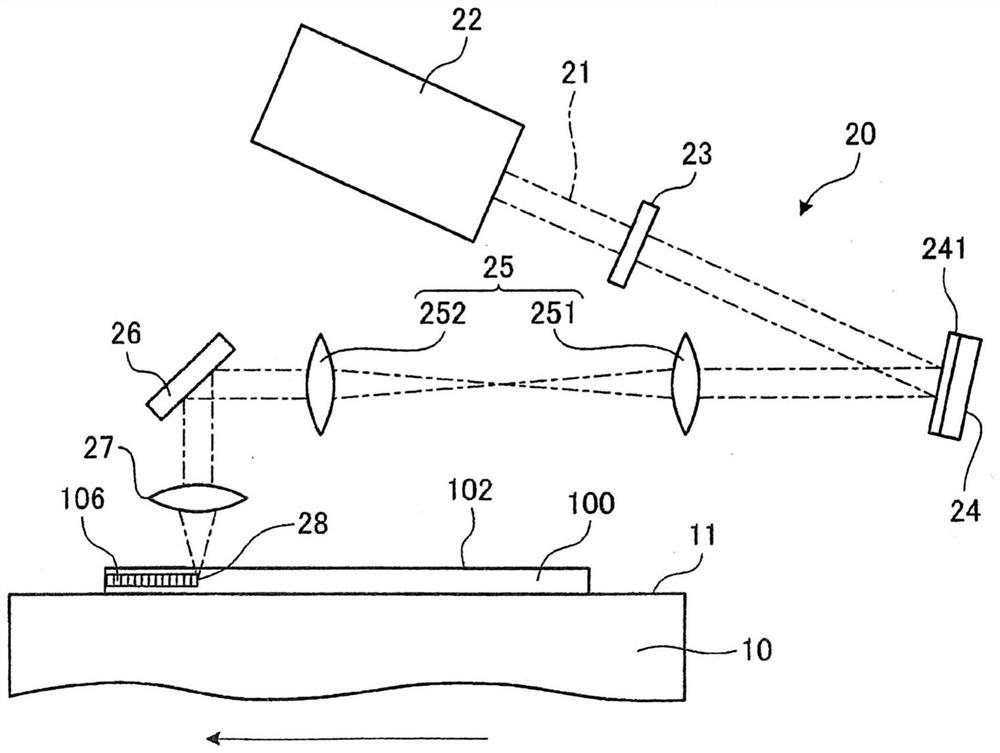

[0027] Such as fig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap