Paper feeding door locking mechanism and printing machine using same

A technology of door locking and printing machine, applied in printing, stamping and other directions, can solve the problem of inaccurate position of the seal, and achieve the effect of small occupied space and simple mechanical mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

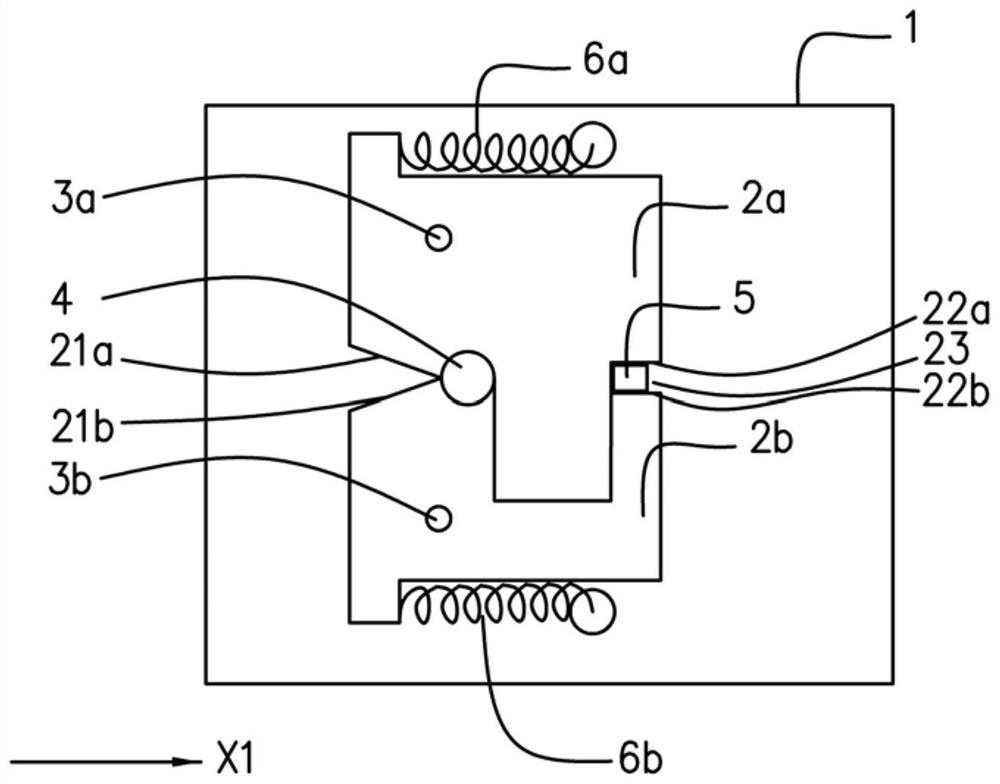

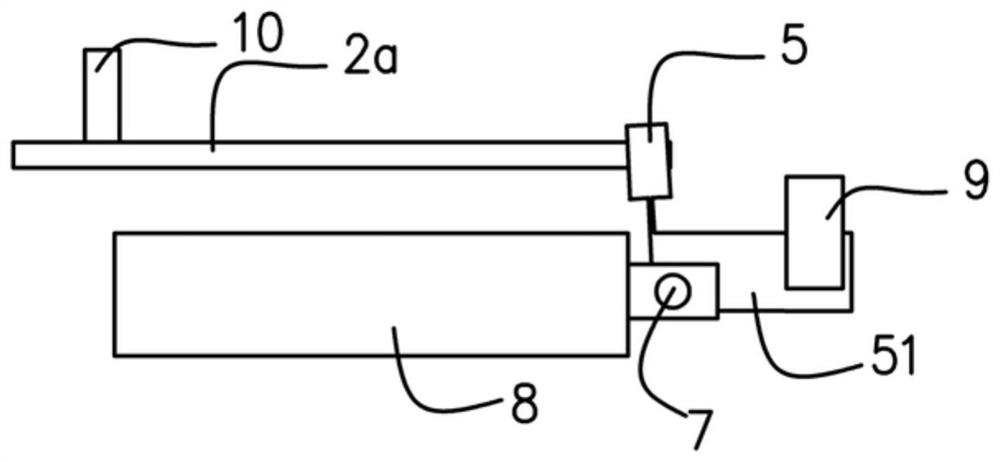

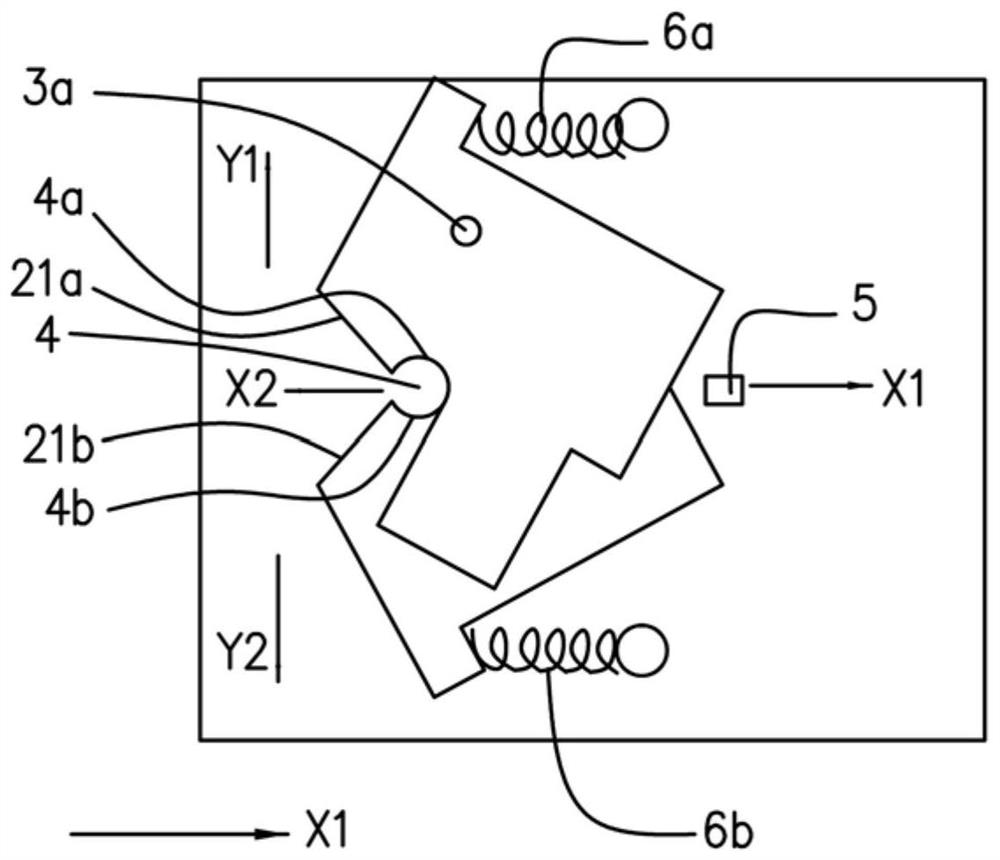

[0034] In order for those skilled in the art to better understand the technical solution of the present invention, the paper feed door locking mechanism provided by the present invention and the printer using it will be described in detail below in conjunction with the accompanying drawings.

[0035] The bottom plate in the printing machine is arranged in the body of the printing machine to carry parts such as the paper feeding door; It is located at one end inside the body of the printer) to lock the paper feed door at the designated position in the printer, or to automatically eject the paper feed door from the printer (that is, to make the paper feed door relative to the printer’s horizontally protruding part of the outer surface).

[0036] Specifically, please also refer to Figure 1 to Figure 4 , the paper feed door locking mechanism is installed on the base plate 1, and includes two limiters (2a, 2b), a pusher 10 and a locking assembly, wherein the two limiters (2a, 2b)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com