Wind power generation blade mounting jigger positioning sensor

A technology of wind power generation blades and positioning sensors, which is applied in the assembly of wind turbines, wind energy power generation, wind turbines, etc., can solve problems such as unfavorable positioning accuracy and poor positioning effect, and achieve the effect of ensuring positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

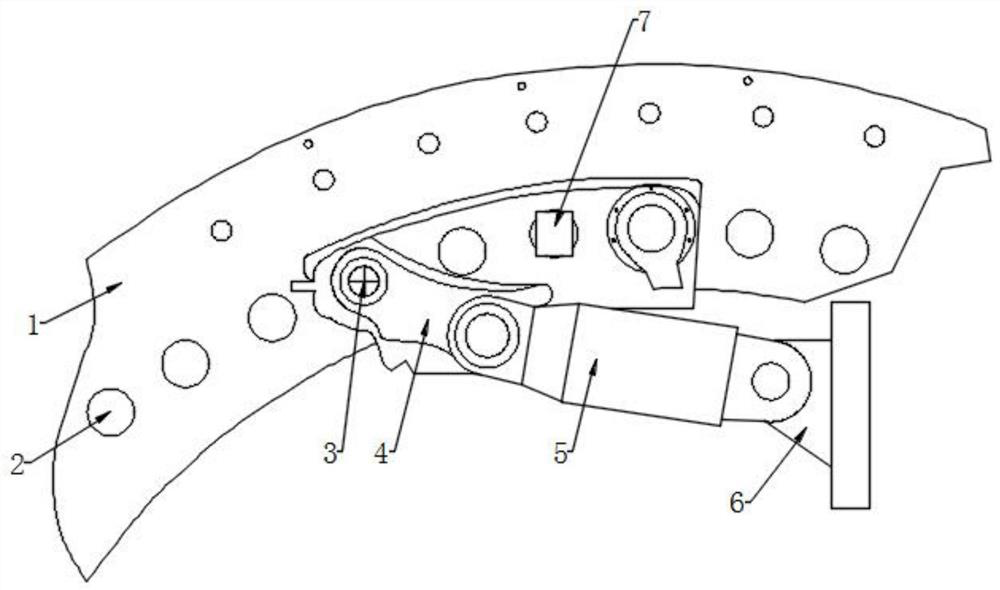

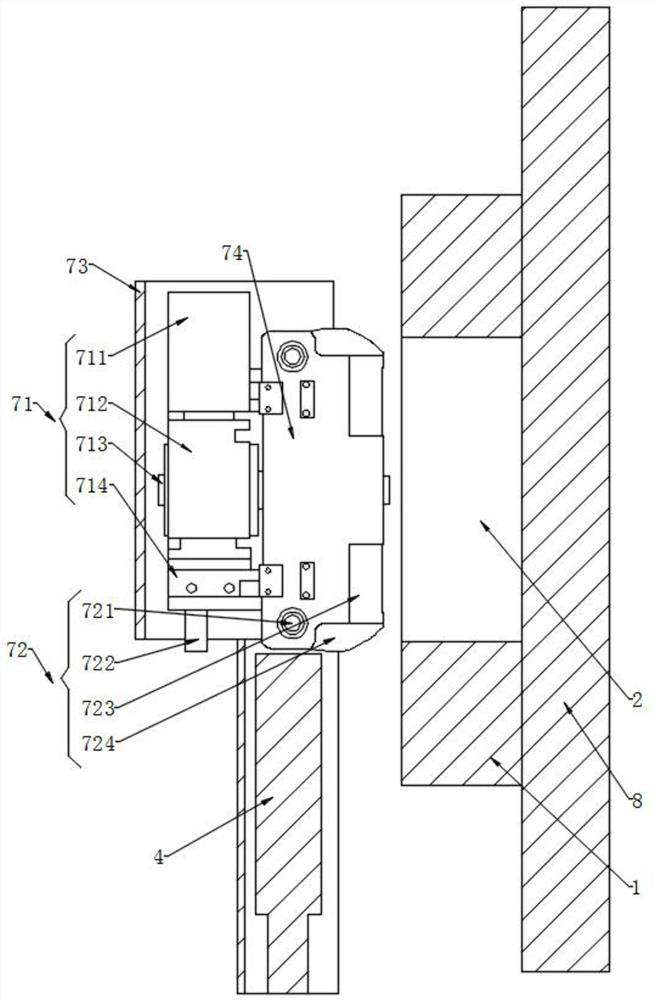

[0021] see Figure 1-2 , the present invention provides the following technical solutions: a wind power generation blade installation barring positioning sensor, including a support seat 6 and a fan blade mounting seat 8, the side of the fan blade mounting seat 8 is fixedly installed with a barring disc 1, and the barring disc 1 There are several connecting holes 2 on the surface of the connecting hole 2, and a swing arm shaft 3 is plugged into one of the connecting holes 2. By setting the connecting hole 2, the connecting hole 2 is aligned with the pin hole on the swing arm 4. By inserting the swing arm shaft 3, The connection between the turning disk 1 and the swing arm 4 can be achieved, and then the purpose of rotating the turning disk 1 can be achieved by means of the hydraulic cylinder 5 stretching and contracting.

[0022] The surface of the swing arm shaft 3 is sleeved with a swing arm 4, and a hydraulic cylinder 5 is movably connected between the surface of the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com