Oven device

A kind of oven and furnace furnace technology, which is applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc. It can solve the problems of cumbersome and time-consuming procedures, difficult oil residue removal, and insulation cotton filling dead corners, etc., to solve the difficulty of assembly , to achieve real-time monitoring, to prevent the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

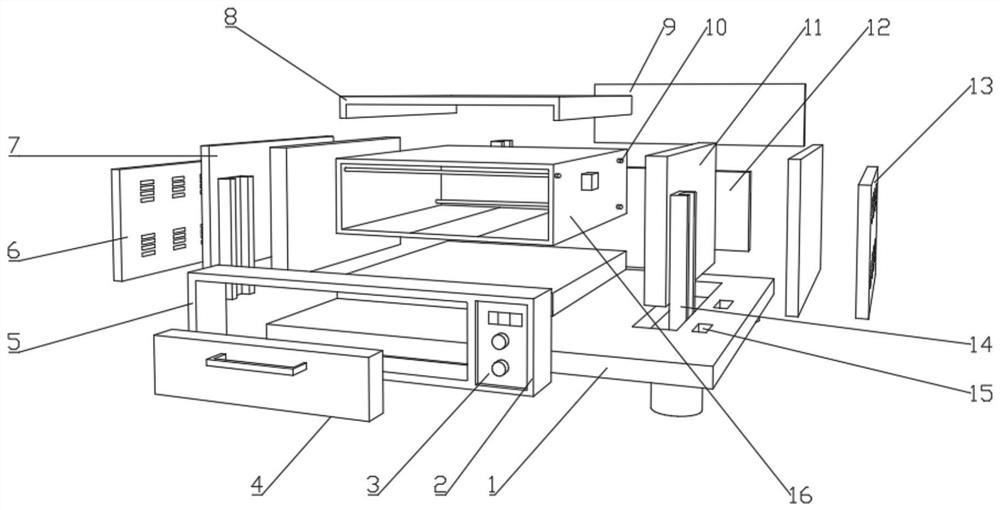

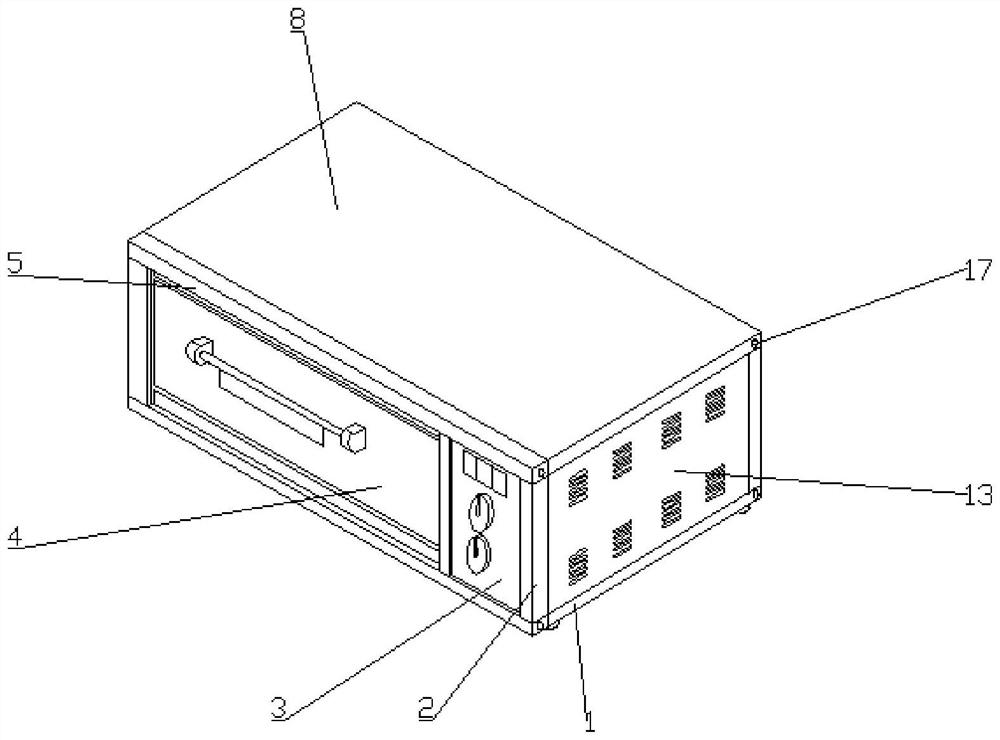

[0018] Example: such as Figure 1-2 As shown, an oven device of the present invention comprises a base 1, a furnace 16 and a heating pipe 10, one side of the base 1 is provided with a furnace door frame 5, and both sides of the furnace door frame 5 are provided with edge guards 2, and the edge guards 2 Screw holes 17 are provided on the top side of the furnace, and the edge guard rod 2 is fixedly connected with the furnace door frame 5 by screws. One side of the furnace door frame 5 is provided with an adjustment panel 3, and the top side of the adjustment panel 3 is provided with a temperature display, and the adjustment panel 3 A circuit board is provided inside the furnace door frame 5, a furnace door panel 4 is provided on one side of the furnace door frame 5, a rock wool board 11 is provided on both sides of the base 1, a support plate 7 is provided on the outside of the rock wool board 11, and a support board 7 is provided on one side of the support board 7. There is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com