Audio test system and test method

A technology of audio testing and testing equipment, which is applied in the direction of electrical components, etc., and can solve problems such as high testing cost, low testing efficiency, and low utilization rate of acoustic testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

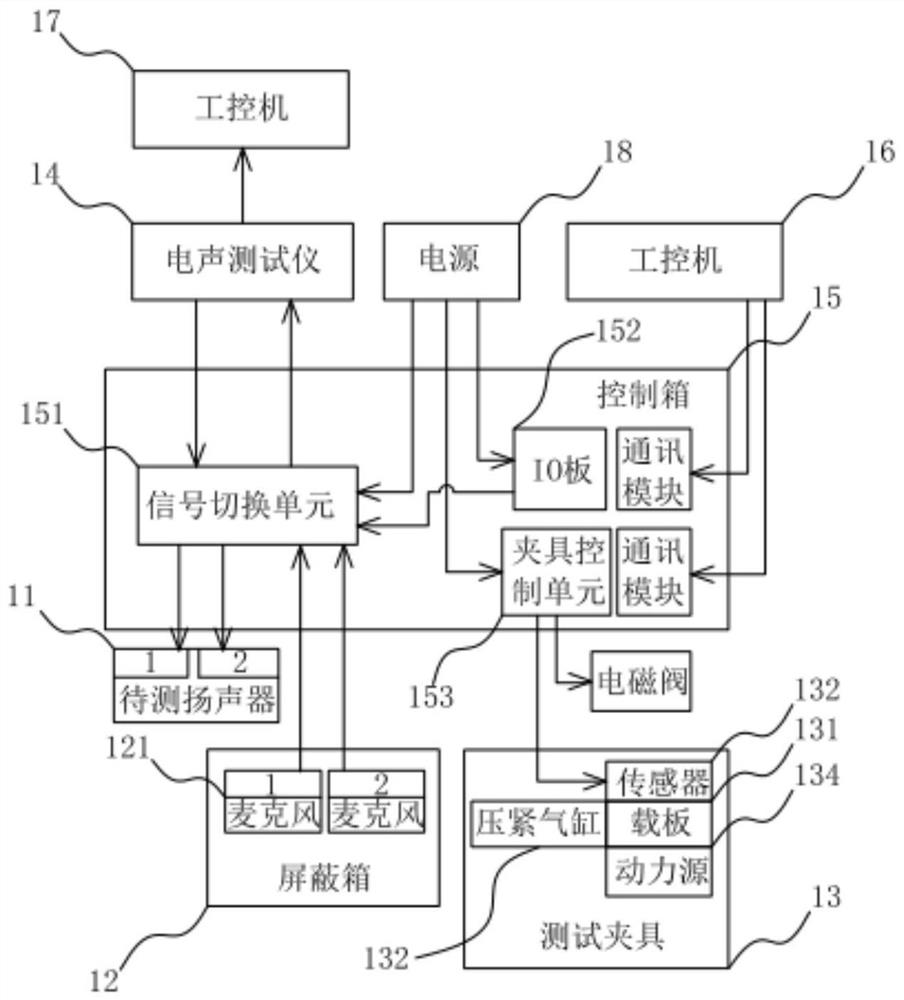

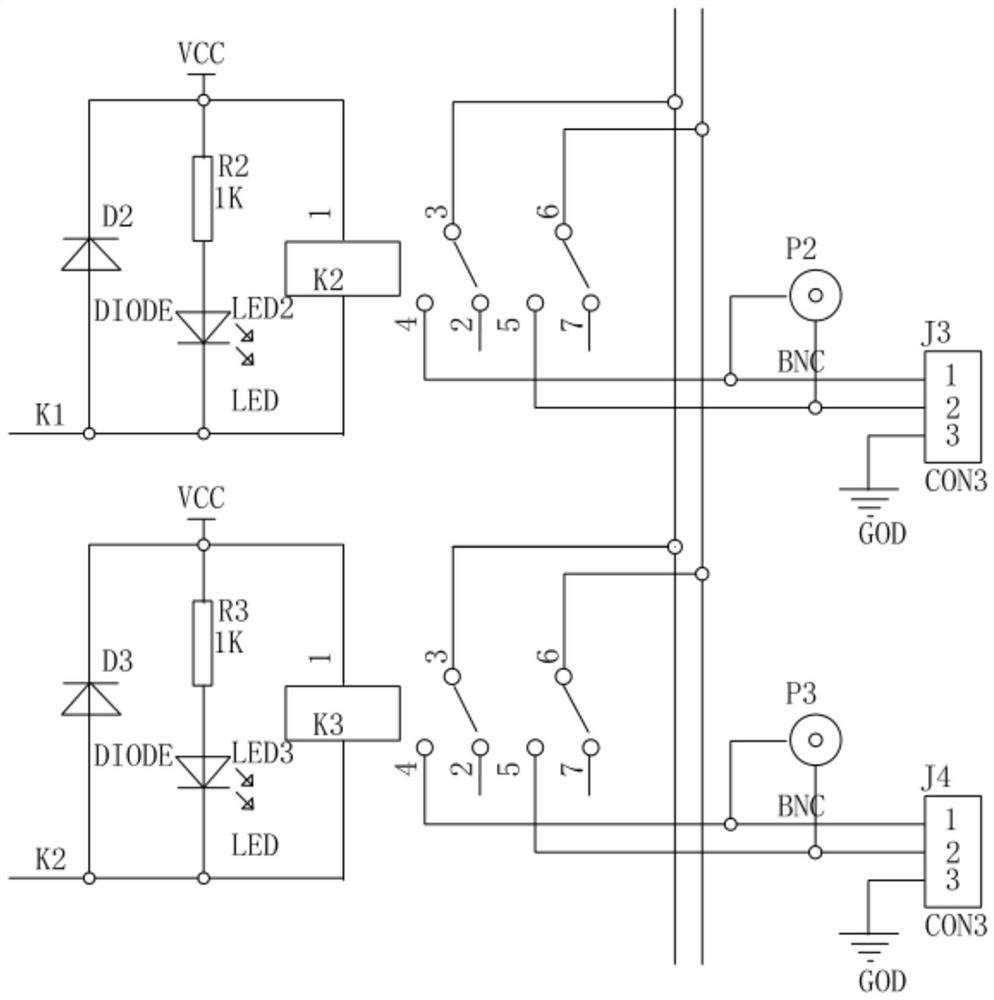

[0049] In Embodiment 1 of the present invention, as figure 1 As shown, an audio test system 10 is applied to the audio test of speakers with a multi-speaker structure; wherein, the product of a speaker with a multi-speaker structure in this embodiment is a speaker with a double-speaker structure. The audio test system 10 for the speaker to be tested 11 of the double-speaker structure includes a shielding box 12, a test fixture 13, an electroacoustic tester 14, a control box 15, an industrial computer 16 and a host computer 17, preferably, the shielding box 12. The test fixture 13, the electroacoustic tester 14, the control box 15, the industrial computer 16 and the host computer 17 are integrated on one test equipment machine. Wherein, the control box 15 includes a signal switching unit 151, an IO board 152 and a fixture control unit 153; specifically, the industrial computer 16 controls the IO board 152 and the fixture control unit 153 respectively through a communication mod...

Embodiment 2

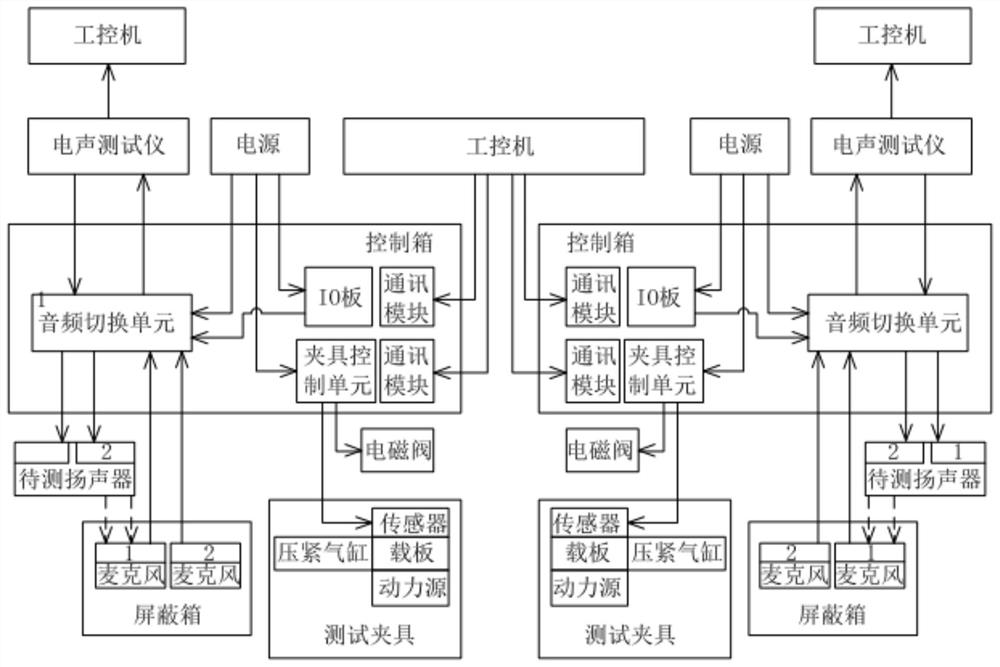

[0058] In the second embodiment of the present invention, as image 3 As shown, an audio test system is applied to the audio test of a speaker with a multi-speaker structure. In this embodiment, the audio test of two speakers with a double-speaker structure can be implemented simultaneously and independently. Its specific test system is the same as that of Embodiment 1, so it will not be repeated one by one.

Embodiment 3

[0060] In the third embodiment of the present invention, as Figure 4 As shown, an audio test method is applied to the audio test of speakers with a multi-speaker structure; the audio test method is based on the above-mentioned audio test system, and the audio test method includes the following steps S101 to S107:

[0061] Step S101: the fixture control unit receives the input signal of the level change of the Start button, sends an instruction to the industrial computer, and sends a signal to the fixture control unit after the industrial computer receives the instruction.

[0062] Step S102: The fixture control unit receives the signal, controls the compression cylinder to compress the speaker under test placed on the test fixture, and pushes the compressed speaker under test to the One side of the shielding box of the sound outlet, so that each horn sound point of the speaker to be tested is set in one-to-one correspondence with the microphone through the sound outlet, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap