Filling machine for filling taper paper tube with material

A filling material and filling machine technology, which is applied in the manufacture of cigarettes, food science, applications, etc., can solve the problems of unsuitable cone-shaped paper tubes, etc., and achieve the effects of fast filling, reliable and stable work, and high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

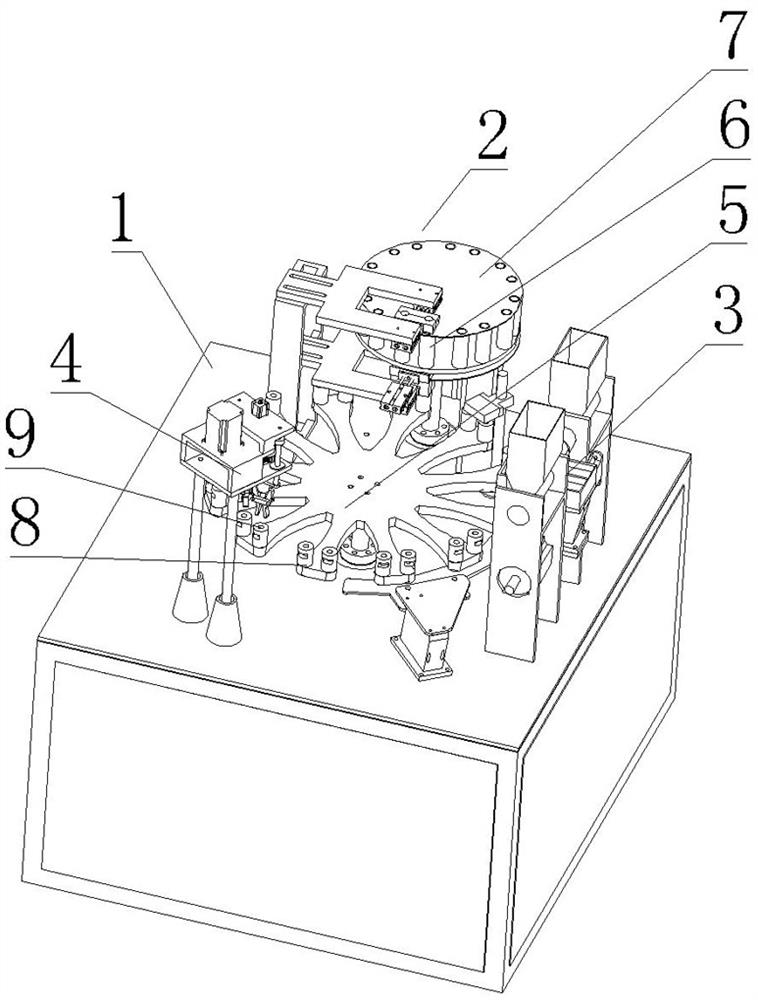

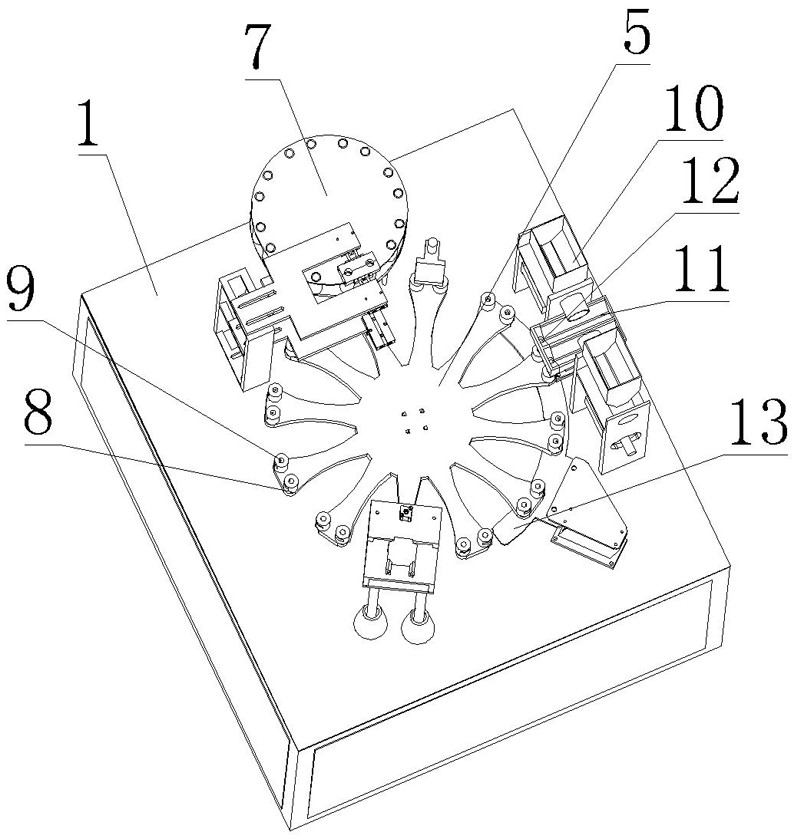

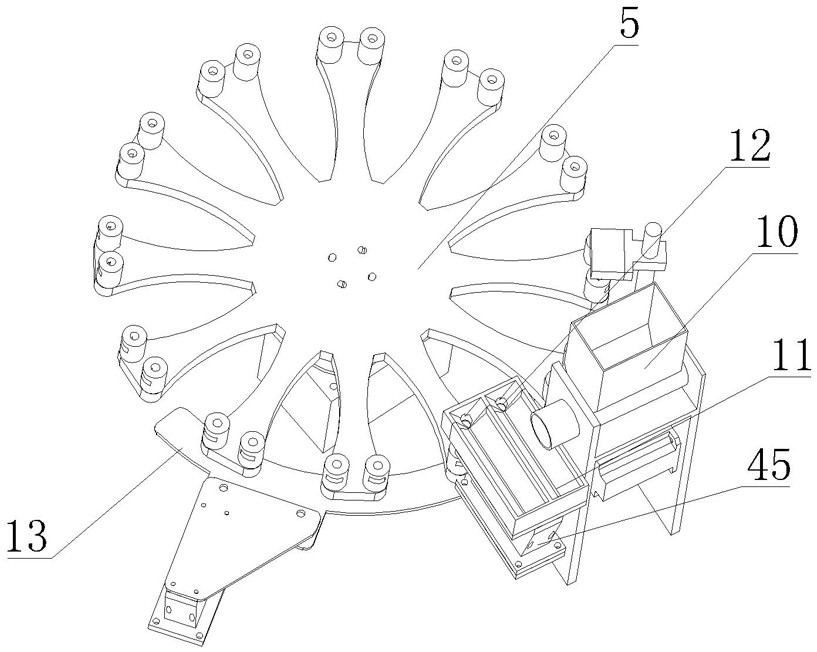

[0027] Referring to the accompanying drawings, this filling machine for filling materials in tapered paper tubes includes a tapered paper tube dropping device 2, an indexing plate 5 and a blanking device 3, and the blanking device 3 is arranged on the bottom of the indexing plate 5. On one side, the circumference of the index plate 5 is provided with a paper tube positioning seat 8 for positioning the tapered paper tube, and the tapered paper tube dropping device 2 is used to drop the tapered paper tube into the indexing In the paper tube positioning seat 8 on the disc 5, the said blanking device 3 is used to fill the material into the tapered paper tube. In this embodiment, cigarettes are taken as an example for description.

[0028] Wherein, the tapered paper tube dropping device 2 has a turntable 7, the turntable 7 is provided with an intubation tube 6, and a second moving block 26 is arranged below the turntable 7, and one side of the second moving block 26 A first moving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap