Waste guiding-out system of sawing machine

A waste material and sawing machine technology, which is applied to the attachment of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems that affect the continuous operation of cutting, low efficiency, easy to burn cleaning personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

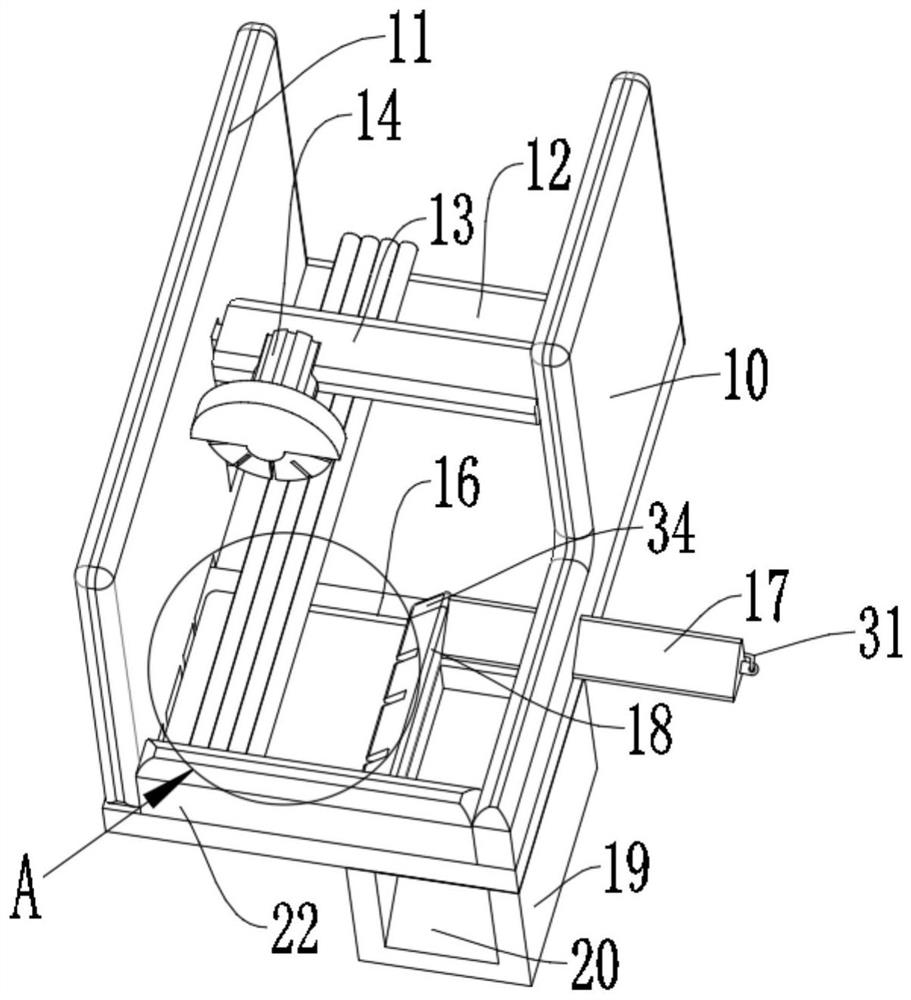

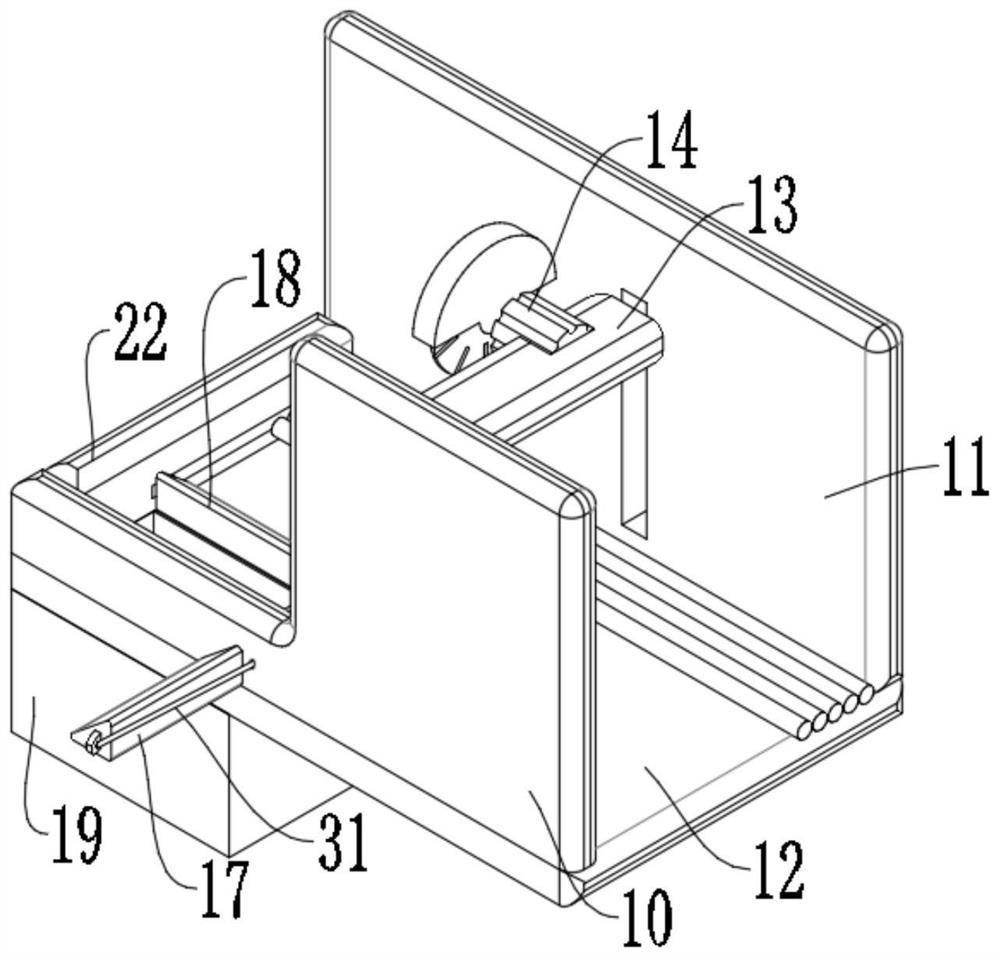

[0026] refer to figure 1 , image 3 , Figure 4 with Figure 5 As shown, the present embodiment provides a waste material exporting system of a saw machine, which is mainly used to clean up waste materials and leftover materials in a timely manner during the processing of pipes or plates.

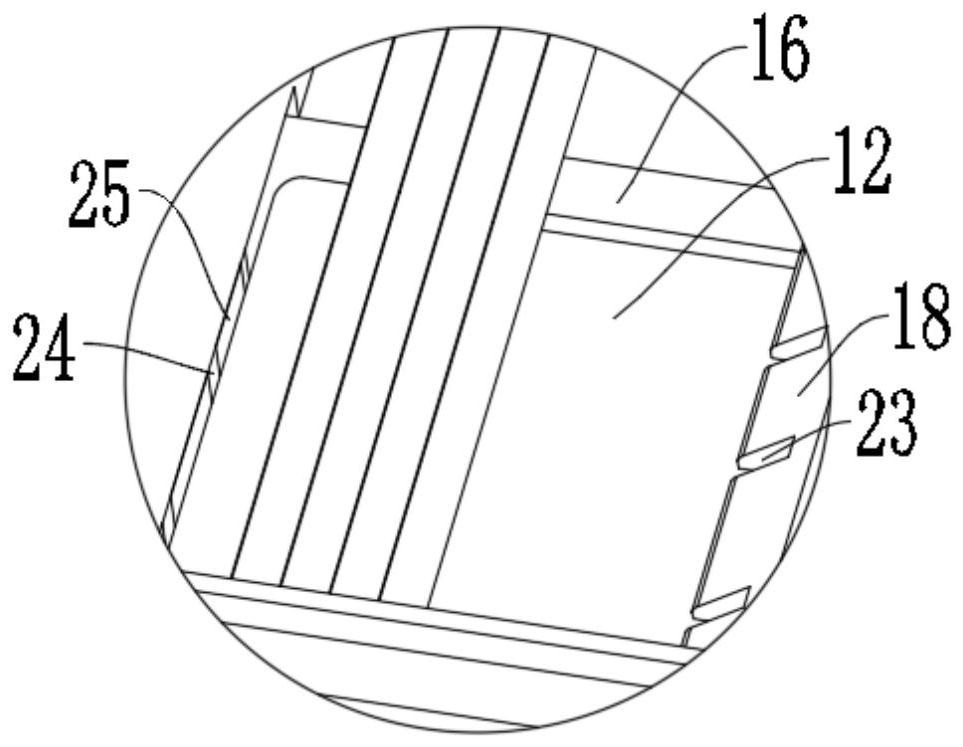

[0027] Including a cutting table 12 and a lift table 13, the lift table 13 is vertically slidably connected with the cutting table 12, and includes a cleaning mechanism, the cleaning mechanism includes a push plate 18 and a storage groove 25, the push plate 18 is connected to the The cutting table 12 is horizontally slidably connected, and one side of the push plate 18 is an inclined surface. The push plate 18 is used to separate waste materials and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com