Cooling shelling mechanism based on injection molding machine and use method of cooling shelling mechanism

A technology of injection molding machine and main body, applied in the field of cooling and shelling mechanism, can solve the problems of lowering product quality, being easy to hang on the mold, time-consuming and laborious, etc., and achieving the effects of improving production quality, preventing friction and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

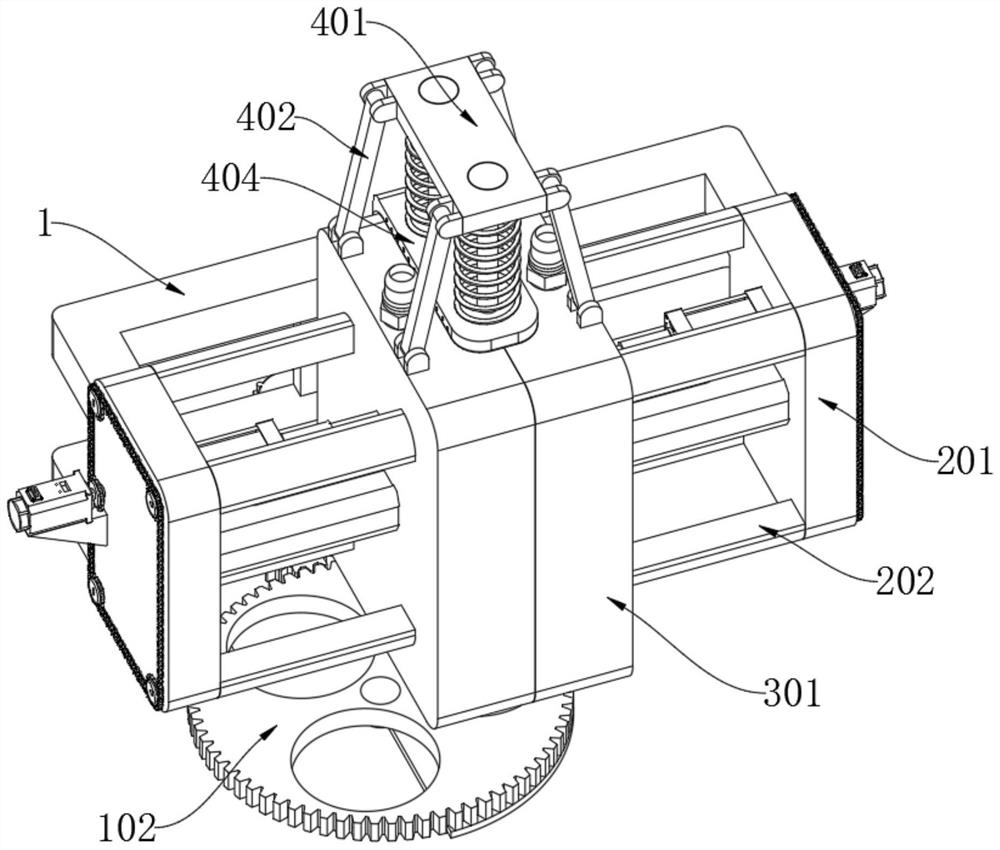

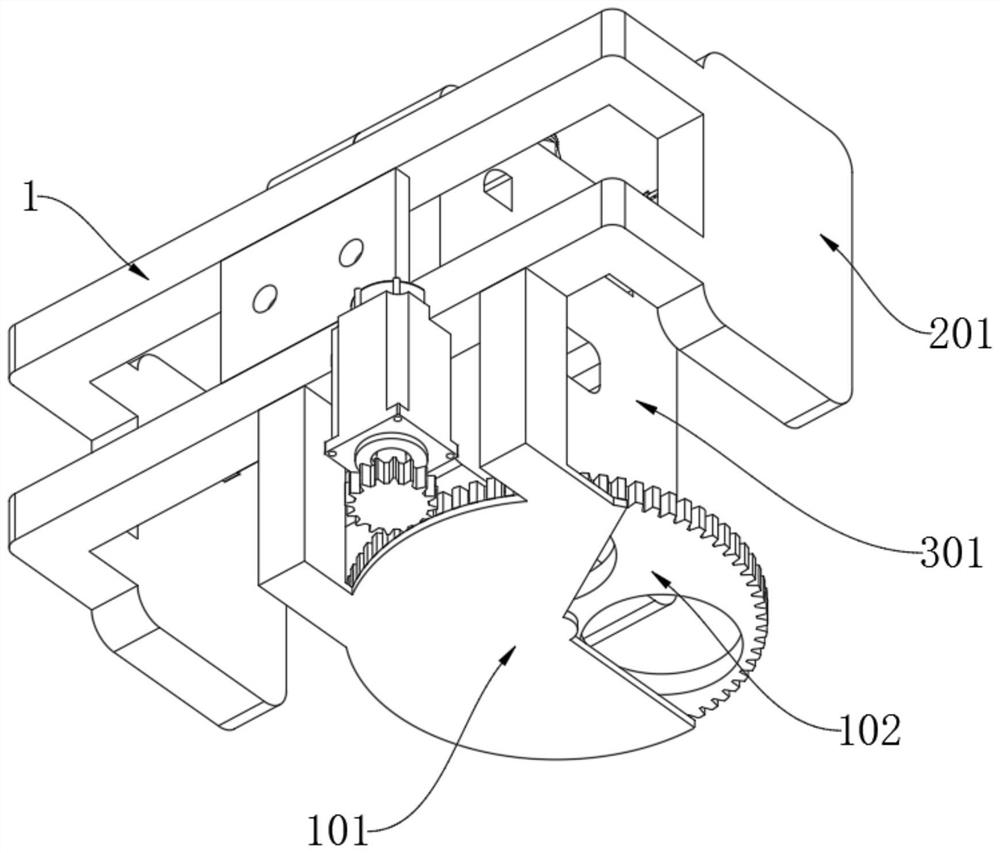

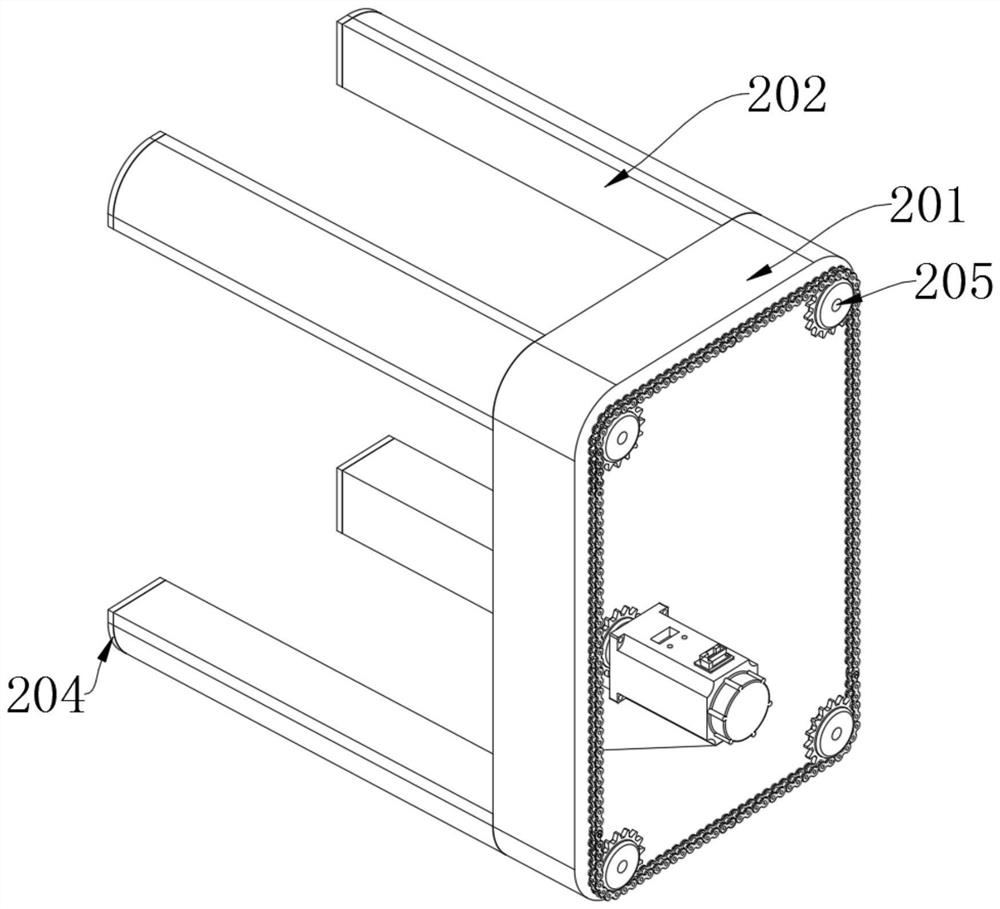

[0038] as attached figure 1 to attach Figure 7 Shown:

[0039] The invention provides a cooling and shelling mechanism based on an injection molding machine and its use method, comprising: a main body 1, a motor is installed at the bottom of the main body 1, a gear is installed at the bottom end of the motor, and a stripping part 2 is installed on the side of the main body 1 The demoulding part 2, the carrier plate 201 in the demoulding part 2 is located at the two ends of the main body 1, the side of the carrier plate 201 is equipped with a cylinder, and the side of the demoulding part 2 is equipped with a cooling part 3; The side of the splint 301 in the part 3 is provided with a plurality of openings, and the horizontal plate 202 is installed in the opening on the side of the splint 301, the side of the splint 301 is connected with the cylinder on the side of the carrier plate 201, and the slide plate in the cooling part 3 303 is located on the side of the carrier plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com