Manipulator with hydraulic quick-change connector

A manipulator and hydraulic technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of dust-proof and blocking of hydraulic interfaces, inability to push attachments through oil cylinders, fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

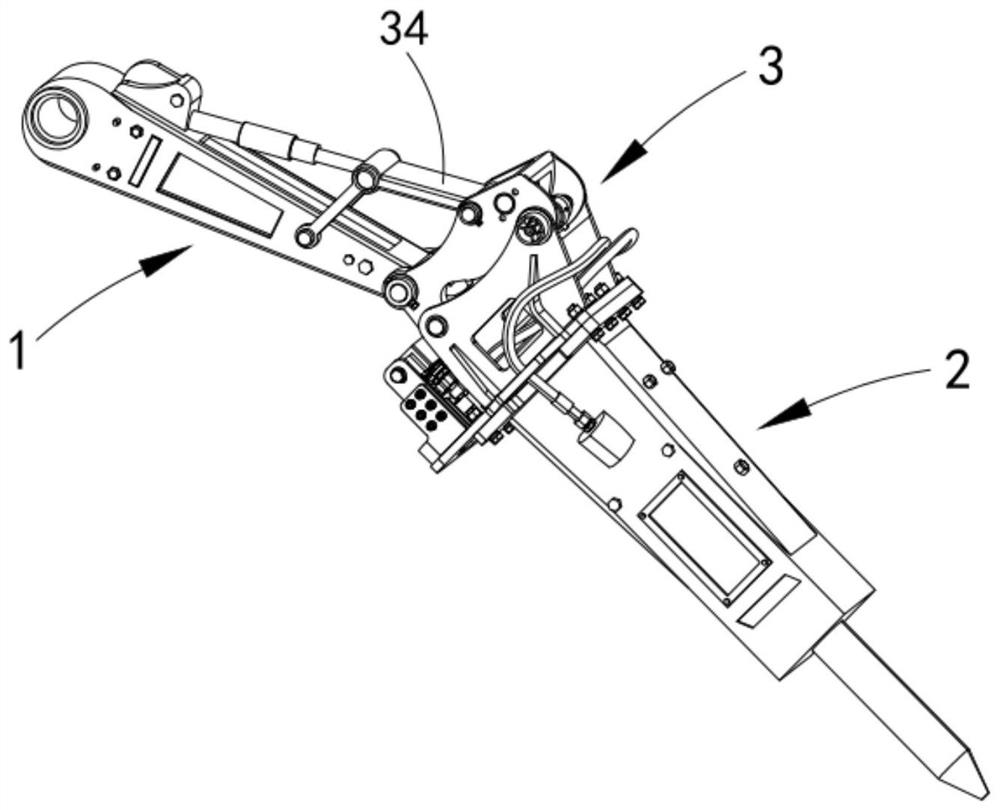

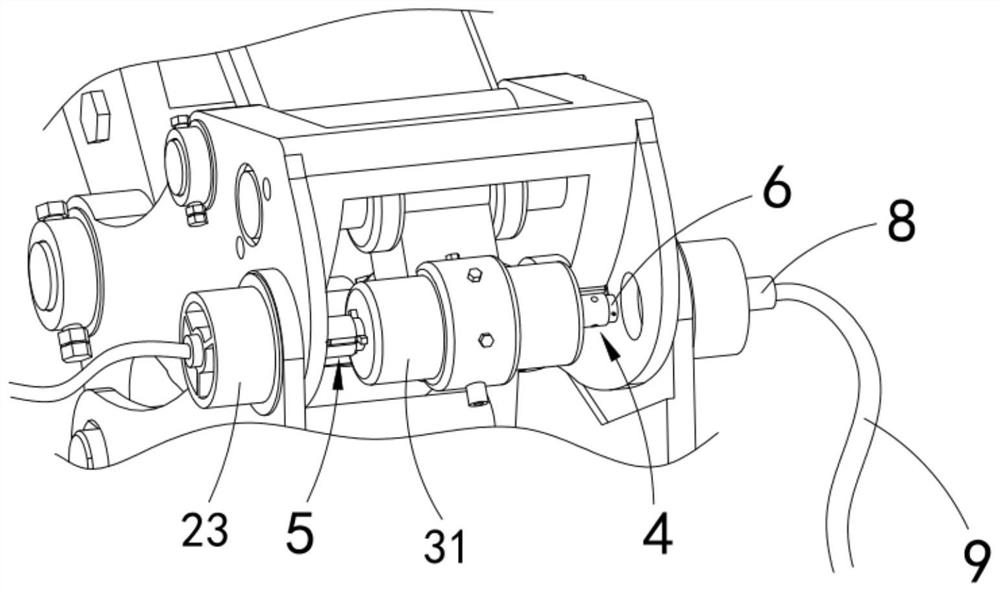

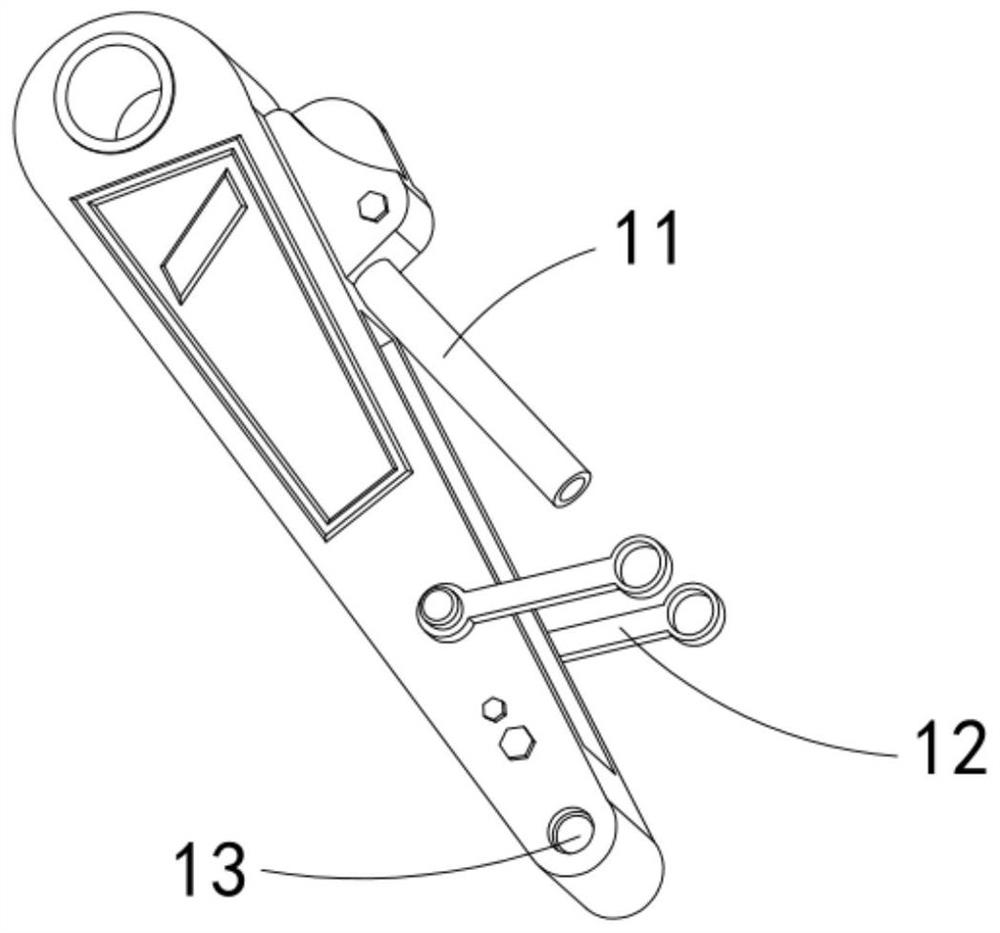

[0035] Such as Figure 1 to Figure 10 As shown, a manipulator with a hydraulic quick-change joint includes a third arm 1 and an attachment 2, a quick-change joint 3 is arranged between the third arm 1 and the attachment 2, and the quick-change joint 3 is provided with There is an oil cylinder 31, the two ends of the oil cylinder 31 are slidingly provided with a pusher 4, one end of the pusher 4 is provided with an expansion assembly 5 and a hydraulic interface a6, and a number of extruding parts are slidably arranged on the pushe...

Embodiment 2

[0047] Such as Figure 8 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that a cover 53 is also provided on one side of the arc panel 52 .

[0048] Here, in this embodiment, a cover 53 is provided on the side of the arc panel 52. When the quick-change joint 3 is not equipped with the attachment 2, it can effectively prevent impurities and dust in the working area from entering the hydraulic interface a6, and prevent impurities from affecting the next replacement and installation. Tool 2 makes an impact.

[0049] work process

[0050] First, the driver operates the third arm 1 to drive the quick-change joint 3 to move to the top of the attachment 2 to be installed, and then locks the round rod 24 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com