An explosion-proof metal pressure vessel

A pressure vessel and explosion-proof technology, which is applied in the field of explosion-proof metal pressure vessels, can solve the problems of not being able to adapt to volume changes well, the storage space cannot be changed, and the effect of explosion-proof functions is weakened, so as to achieve stable air pressure and keep air pressure stable , Improve the effect of explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

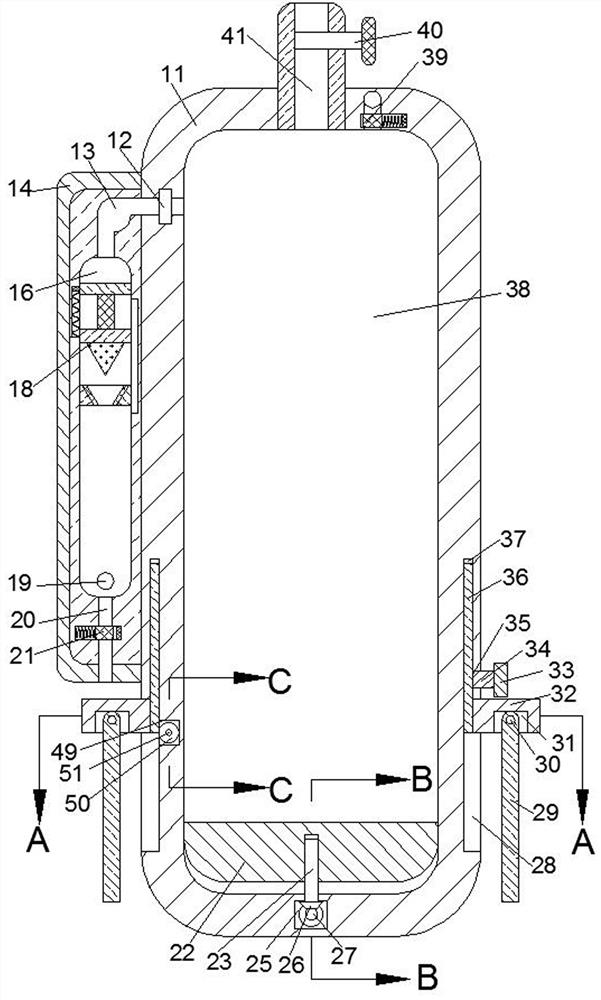

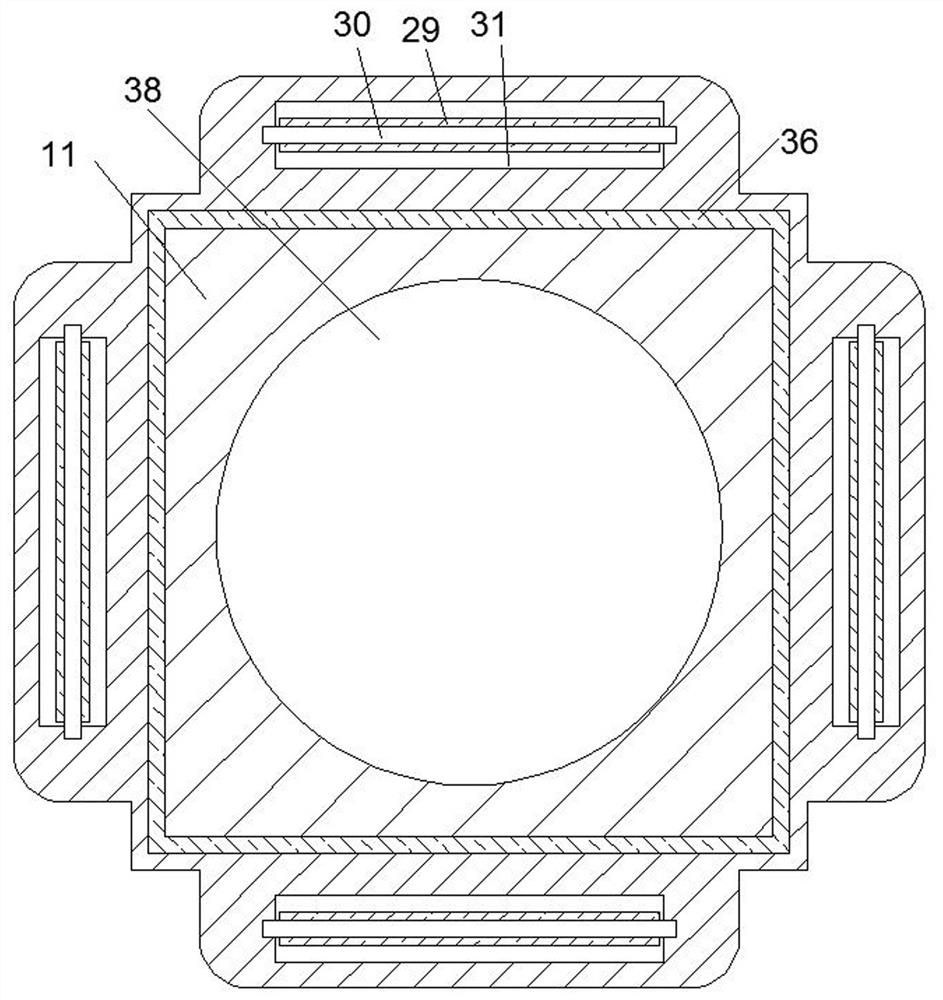

[0025] In order to make the objects and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the examples. It should be understood that the following words are only used to describe an explosion-proof metal pressure vessel of the present invention or several specific implementations, and Without strictly limiting the scope of protection specifically claimed by the present invention, as used herein, the terms up, down, and left and right are not limited to their strict geometric definitions, but include reasonable and inconsistent tolerances for machining or human error, as detailed below Describe the specific features of this explosion-proof metal pressure vessel:

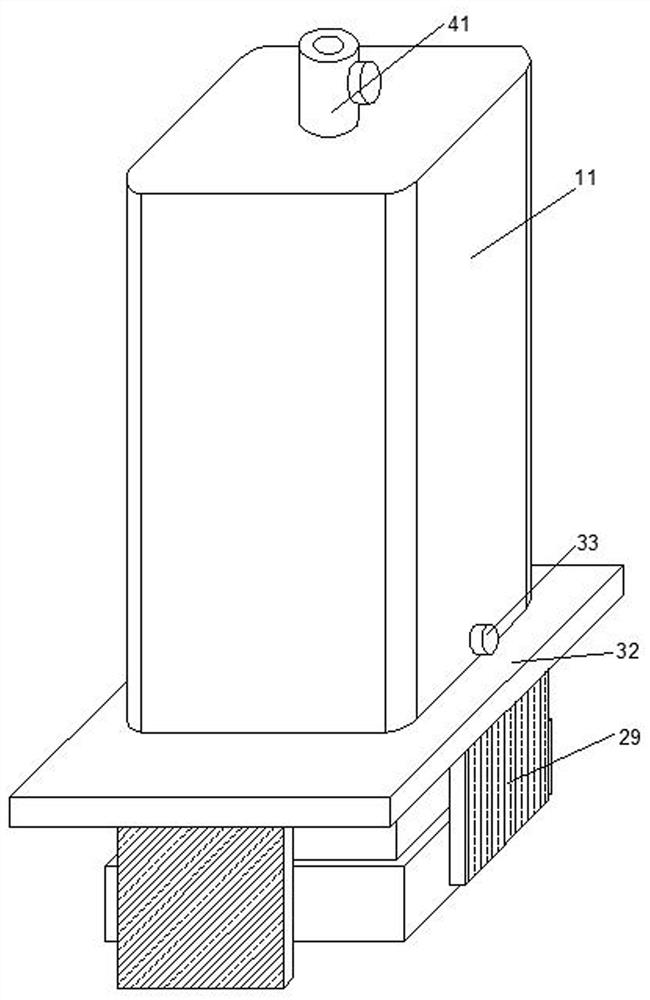

[0026] Refer to attached Figure 1-8, an explosion-proof metal pressure vessel according to an embodiment of the present invention, comprising a main body 11, a working chamber 38 is arranged inside the main body 11, and the upper wall of the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com