An industrial circulating cooling water system and its energy-saving operation method

A technology for circulating cooling water and energy-saving operation. It is applied in the chemical industry, water shower coolers, cooling fluid circulation devices, etc. It can solve the problems of climate characteristics and weather change factors, which cannot meet the control needs of water temperature, cooling tower refrigeration, etc. Insufficient ability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

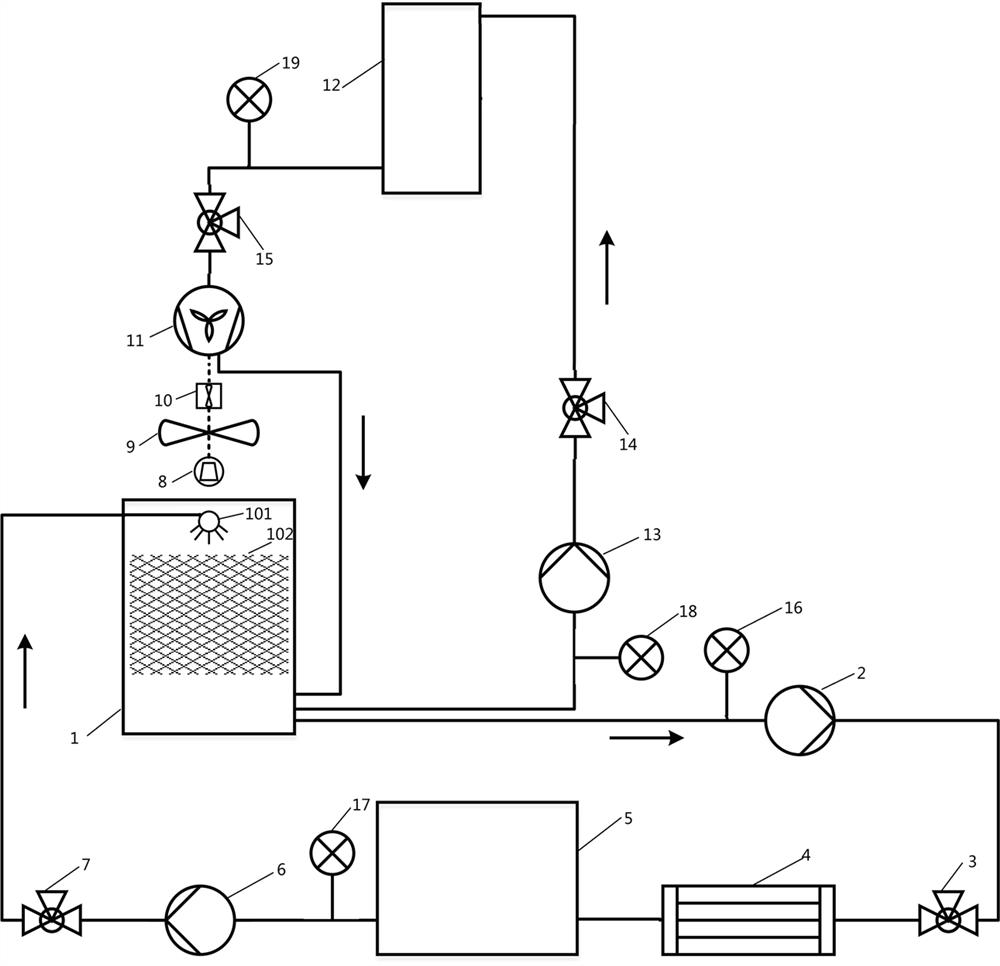

[0028] An iron smelting plant is located in a certain place in northwest China. The area is mountainous and the temperature difference between day and night is large all year round, and the area implements relatively cheap peak-to-valley electricity prices around the early hours of the night. The ironmaking plant uses a circulating cooling water system to cool a certain process equipment. Please refer to the appendix for its composition. figure 1 . The maximum allowable flow value Q of the circulating cooling water system m and the design flow value Q r 600m respectively 3 / h and 500m 3 / h, the rated speed and rated power of the fan 9 are 750r / min and 10kW respectively, and the suitable temperature range of the circulating cooling water flowing into the terminal process equipment 4 during the operation is 18°C to 26°C. In this embodiment, the operation time period of the early morning mode is set from 1 hour before zero o'clock to 2 hours after zero o'clock (that is, fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com