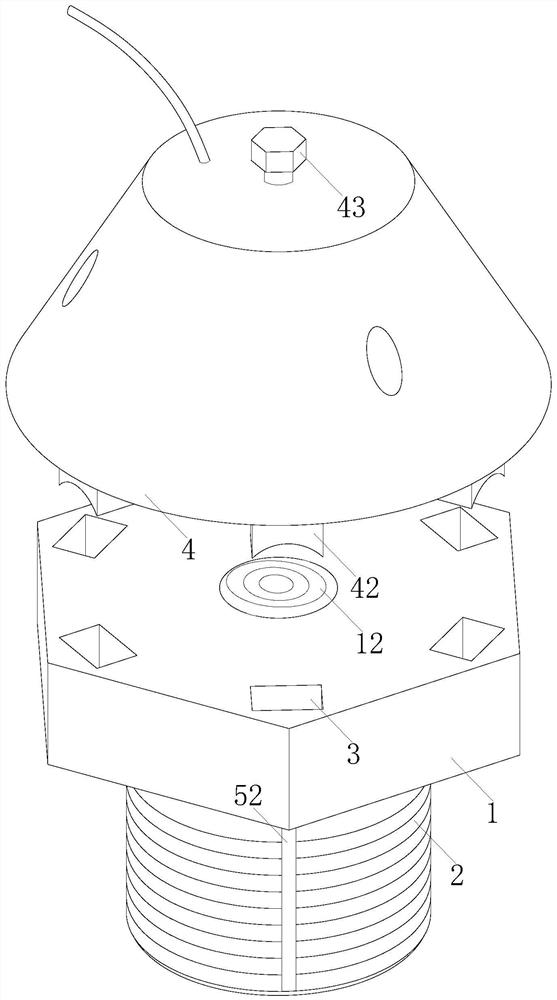

Inductance type water pressure sensor

A water pressure sensor, inductive technology, applied in the sensor field, can solve the problems of reducing the reliability of the sensor, detecting data errors, etc., and achieve the effect of increasing stability, increasing accuracy, and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

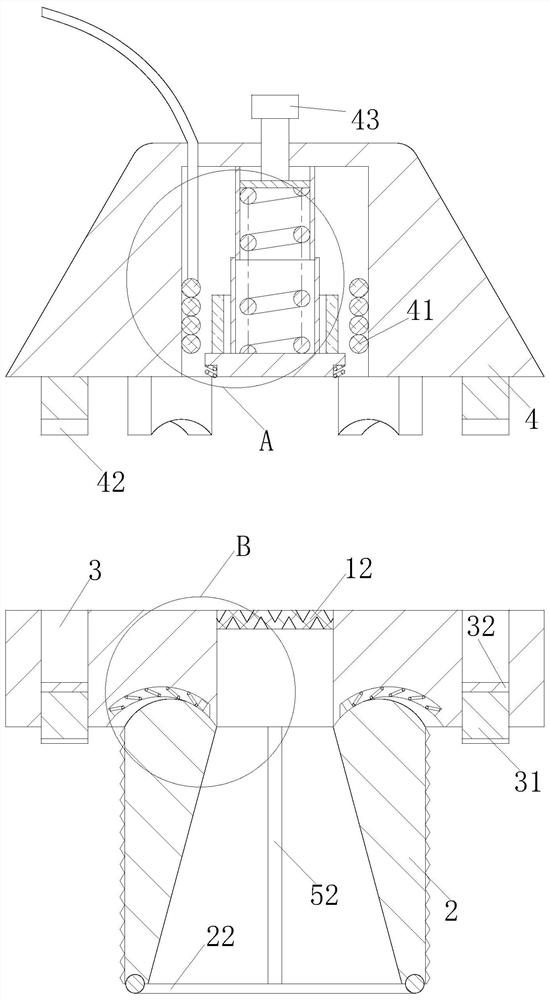

[0033] As an embodiment of the present invention, the end of the arc-shaped plate 2 away from the No. 2 hole 3 is inclined, and when the outer surface of the arc-shaped plate 2 is vertical, the inner surface of the arc-shaped plate 2 is inclined towards the No. 1 hole. 11.

[0034] When in use, as the user continuously rotates the base 1, the arc-shaped plates 2 are guided by the installation holes and limited by the ring 22, so that each arc-shaped plate 2 approaches the No. 1 hole with the ring 22 as the center 11 direction movement, the end of each arc-shaped plate 2 close to the base 1 gradually approaches each other until the arc-shaped plate 2 enters the installation hole, at this time the ends of the arc-shaped plate 2 close to the base 1 are close to each other to form a closed space, due to the arc The end of the shaped plate 2 away from the No. 2 hole 3 is inclined, and when the outer surface of the arc-shaped plate 2 is vertical, the inner surface of the arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com