Lithium battery core and manufacturing method thereof

A manufacturing method and technology for lithium batteries, which are applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as easy deflection and easy movement of positive and negative electrode sheets, so as to ensure energy density and simplify production. Process, the effect of improving the pass rate of lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

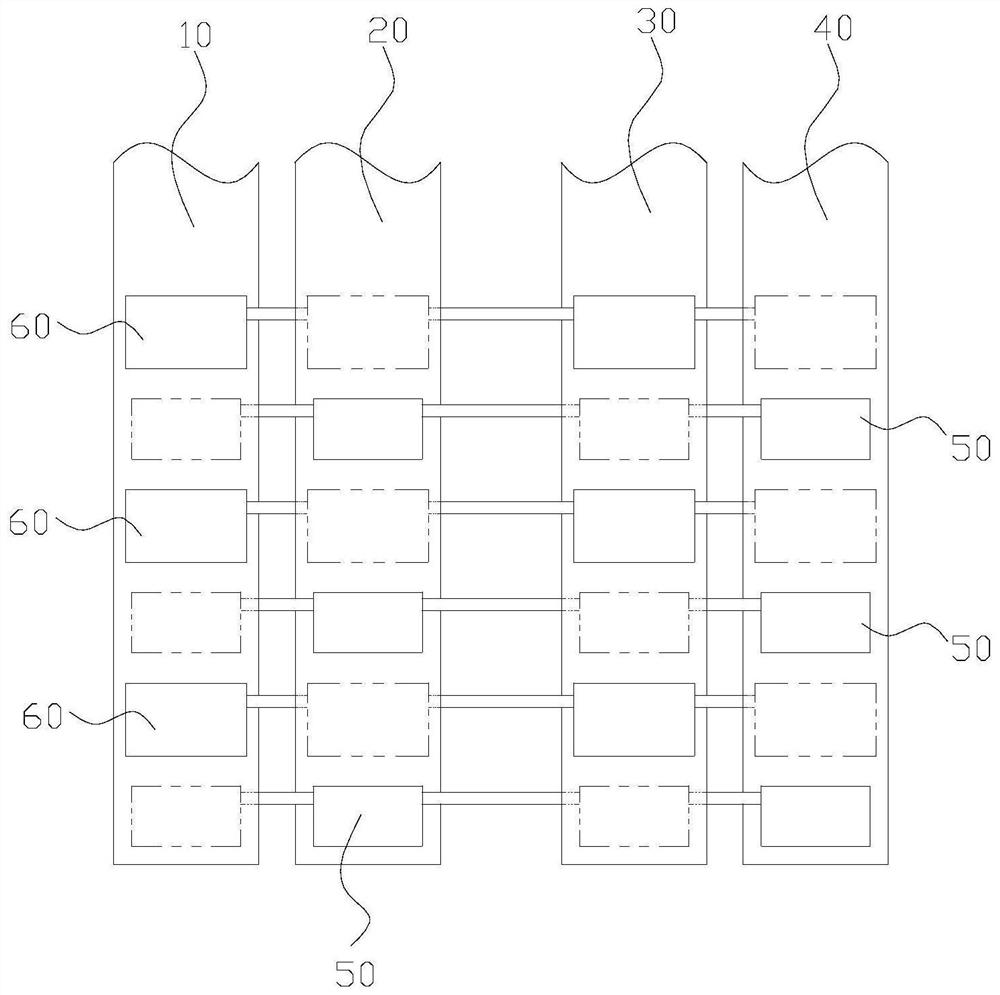

[0067] Such as Figure 18 As shown, the lithium battery cell includes a positive electrode sheet 50, a negative electrode sheet 60, and a diaphragm; in this embodiment, it includes four diaphragms, which are respectively the first diaphragm 10, the second diaphragm 20, the third diaphragm 30, and the fourth diaphragm 40 , but not limited to the number of diaphragms, which can be selected according to actual needs.

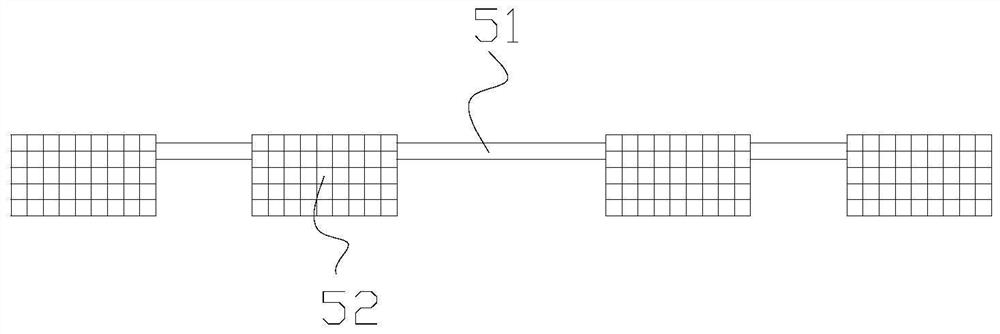

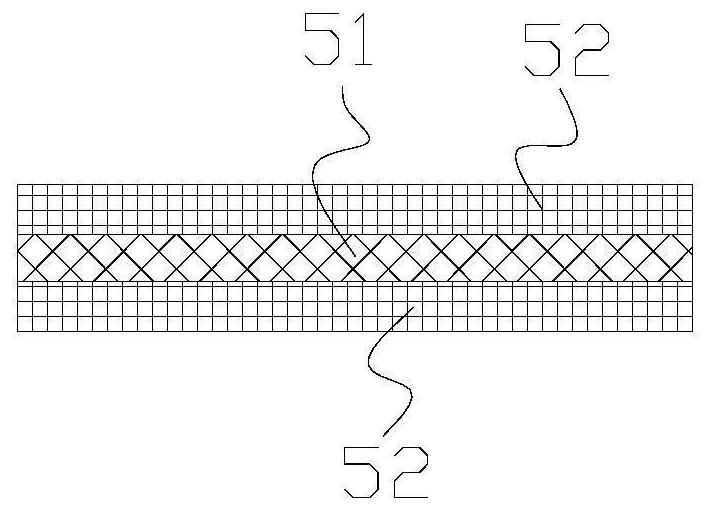

[0068] Such as figure 2 , Figure 16 As shown, the positive electrode sheet 50 includes a positive electrode current collector 51 and a positive electrode active material 52. The positive electrode current collector includes a plurality of spaced parallel first small pieces, and the adjacent first small pieces are connected by a bent blank area, and the blank space The region is strip-shaped, and the positive electrode active material is coated on the side of the first small piece; the number of the separator is the same as the number of the first small piece, s...

Embodiment 2

[0074] This embodiment discloses a manufacturing method for manufacturing lithium battery cells in the first embodiment above, including the following steps:

[0075] Step S01: interspersed;

[0076] Such as figure 1 As shown, in the present embodiment, four diaphragms are included, the first diaphragm 10, the second diaphragm 20, the third diaphragm 30, and the fourth diaphragm 40, and the four diaphragms are arranged at intervals in parallel; wherein the first diaphragm 10 and the second diaphragm The distance between the diaphragms 20, the third diaphragm 30 and the fourth diaphragm 40 is N, the distance between the second diaphragm 20 and the third diaphragm 30 is M, and N Figure 21 );

[0077] In this embodiment, three positive electrode sheets 50 and three negative electrode sheets 60 are included, and the three positive electrode sheets 50 and three negative electrode sheets 60 are sequentially connected to the first diaphragm 10, the second diaphragm 20, and the third...

Embodiment 3

[0102] In this embodiment, in the step S01, the separator is connected to the positive electrode sheet 50 and the negative electrode sheet 60. After the positive electrode sheet 50 and the negative electrode sheet 60 are stacked on the separator, the positive electrode sheet 50 and the negative electrode sheet 60 are bonded together by hot pressing. bonded to the diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com