Cigar tobacco airing device and airing system

A technology of cigar tobacco leaves and drying equipment, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of low work efficiency and heavy handling strength of tobacco drying rods, achieve high degree of automation, avoid instability, and reduce handling strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

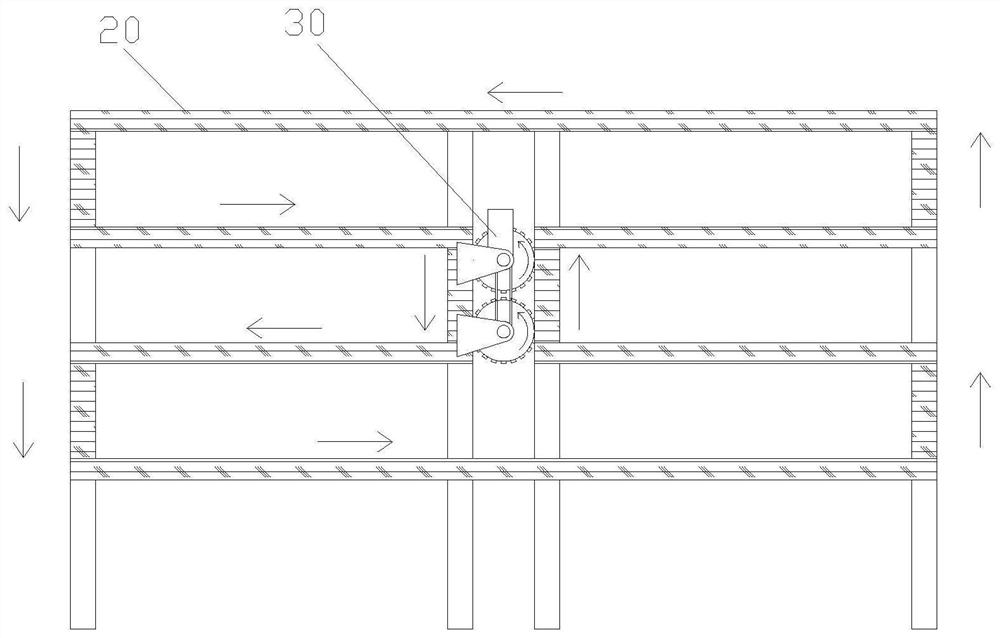

[0041] Such as figure 1 with 2 As shown, a cigar tobacco leaf drying device includes a tobacco drying rod 10, a drying rack 20 and a conveying circuit 30, and the drying rack 20 is equipped with four drying layers.

[0042] Such as figure 1 As shown, in this embodiment, the route that the conveying circuit 30 drives the tobacco airing rod 10 to cycle and change layers between the four airing layers is an I-shaped route.

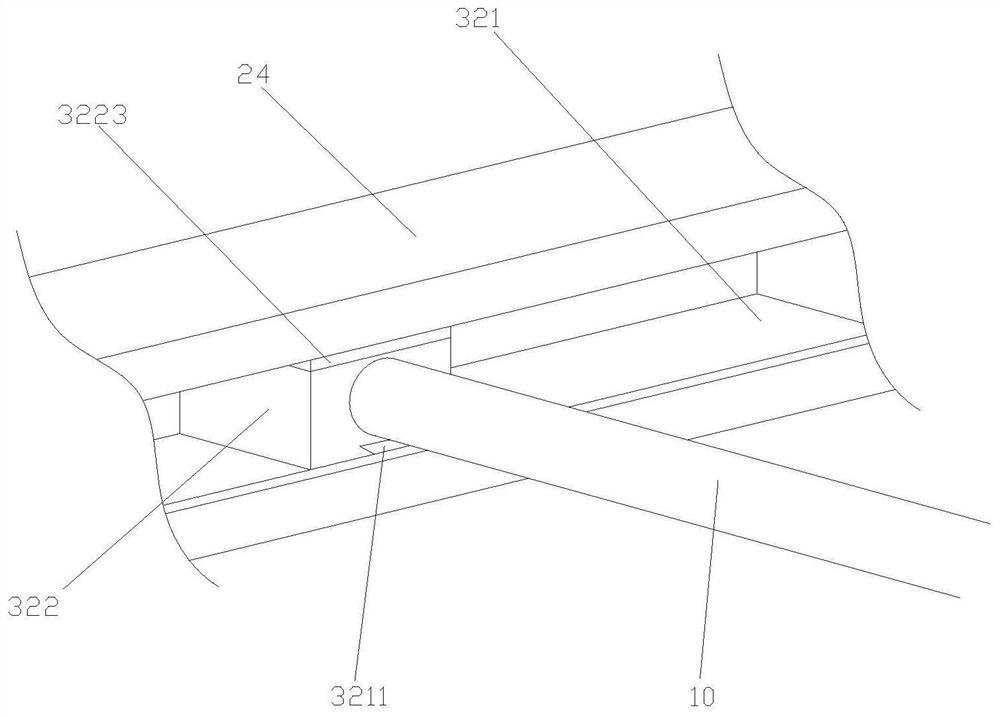

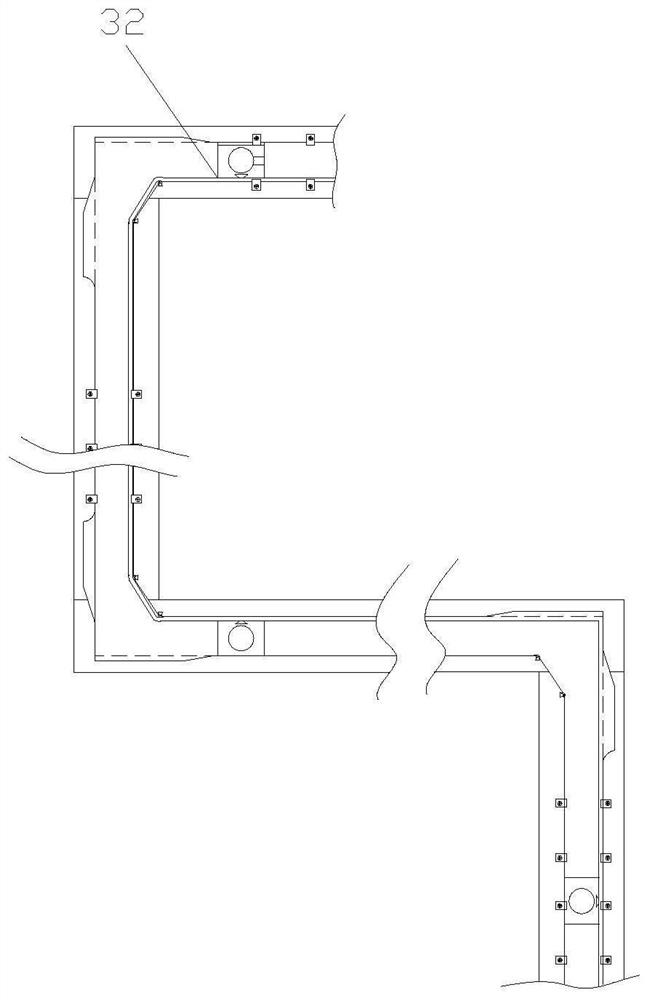

[0043] Such as figure 2 , 3 , 4, 6 and 11, in this embodiment, the conveying circuit 30 includes a power source 31 and two connection circuits 32, the tobacco drying rod 10 is detachably arranged on the connection circuit 32, and the power source 31 is driven by a reduction motor (not shown), the first transmission drum 312, the second transmission drum 313, the first conveyor belt 314 and the installation frame 311, the first transmission drum 312 and the second transmission drum 313 are linked by the first conveyor belt 314, the first The transmission...

Embodiment 2

[0051] Such as figure 2 with 8 As shown, a cigar tobacco leaf drying device includes a tobacco drying rod 10, a drying rack 20 and a conveying circuit 30, and the drying rack 20 is equipped with four drying layers;

[0052] Such as Figure 8 As shown, in this embodiment, the route that the conveying circuit 30 drives the tobacco airing rod 10 to cycle and change layers between the four airing layers is an I-shaped route.

[0053] Such as figure 2 , 3 , 4, 6 and 11, in this embodiment, the conveying circuit 30 includes a power source 31 and two connection circuits 32, the tobacco drying rod 10 is detachably arranged on the connection circuit 32, and the power source 31 is driven by a reduction motor , the first transmission drum 312, the second transmission drum 313, the first conveyor belt 314 and the installation frame 311, the first transmission drum 312 and the second transmission drum 313 are linked by the first conveyor belt 314, and the first transmission drum 312 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com