Building house coating stirring equipment

A kind of mixing equipment and technology for construction, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, dissolving, etc., and can solve problems such as water blockage, sticking, and reducing the quality of seaweed mud coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

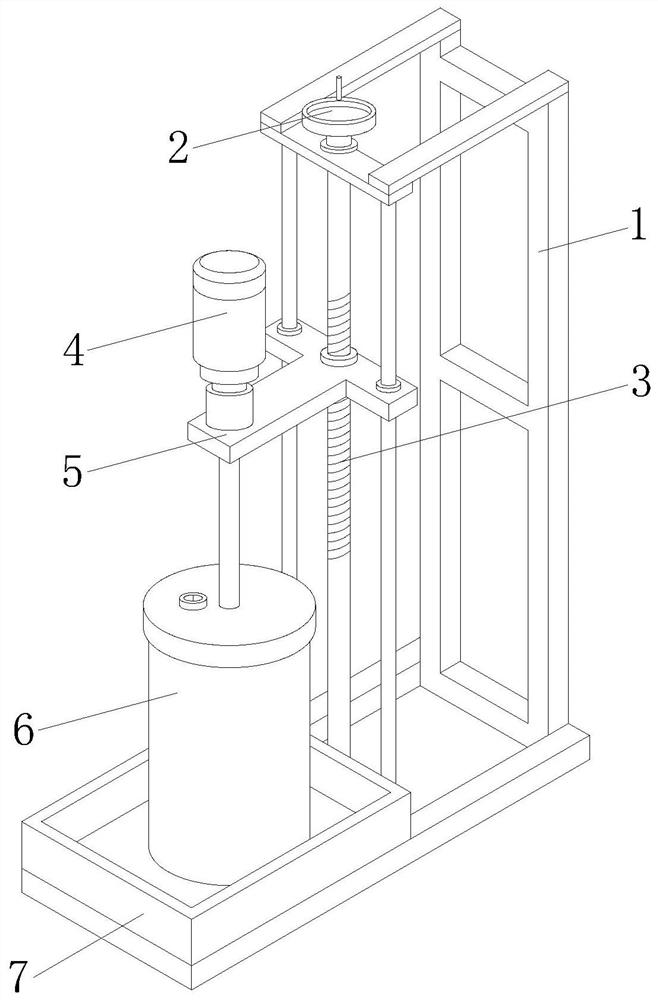

[0022] as attached figure 1 to attach Figure 5 Shown:

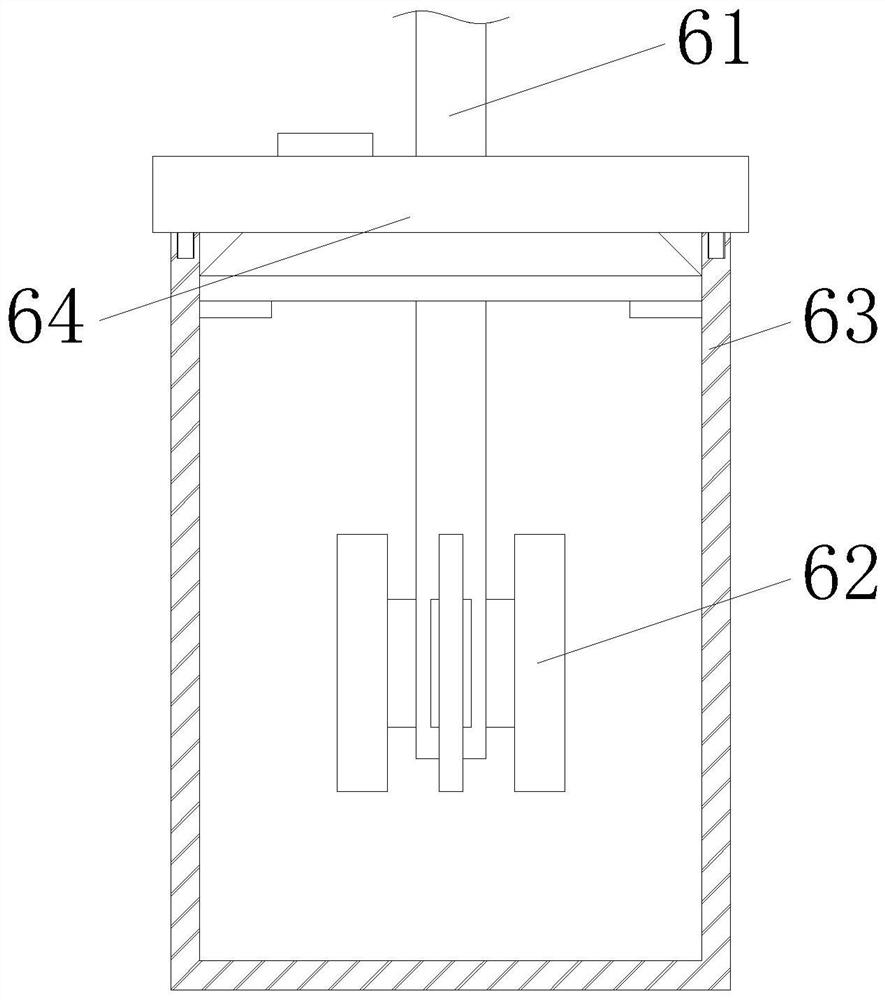

[0023] The present invention is a house paint mixing equipment for building, its structure includes a support frame 1, a hand wheel 2, a screw rod 3, a motor 4, a lifting plate 5, a container device 6, and a bottom plate 7, and the front end of the support frame 1 is provided with a hand wheel 2, and the handwheel 2 is welded to the top of the screw rod 3, the screw rod 3 penetrates the interior of the lifting plate 5 and is threaded, the motor 4 is arranged at the front end of the upper surface of the lifting plate 5, and the output end of the motor 4 is connected to the container device 6. The top rotates synchronously. The bottom of the container device 6 is placed inside the bottom plate 7, and the bottom plate 7 is welded to the bottom of the front end of the support frame 1. The container device 6 includes a connecting rod 61, a stirring blade 62, a container tank 63, a sealing Mechanism 64, the top of the connec...

Embodiment 2

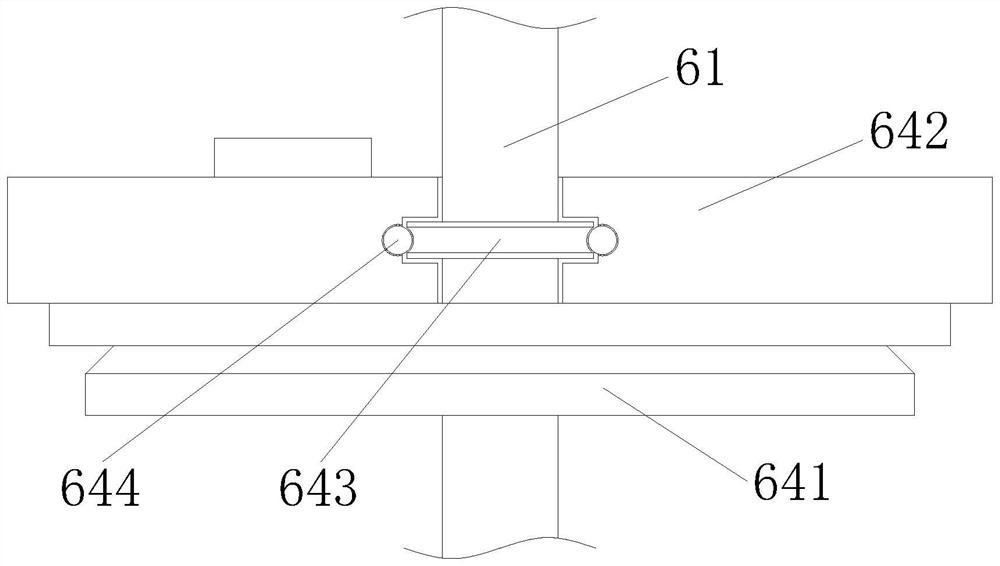

[0030] as attached Figure 6 to attach Figure 7 Shown:

[0031] Wherein, the drainage mechanism 642 includes a cover plate 42a, a water inlet pipe 42b, a spraying mechanism 42c, and a snap ring 42d. The inner lower end of the plate 42a, the snap ring 42d is welded to the bottom of the cover plate 42a, the bottom surface of the cover plate 42a is in conflict with the upper end of the container can 63, the snap ring 42d is embedded in the upper end of the container can 63, and the inside of the cover plate 42a is Hollow structure, and spraying mechanism 42c is provided with sixteen, evenly distributed in the inner lower end of cover plate 42a, is conducive to the clear water in the stirring process is discharged evenly from the interior of spraying mechanism 42c, improves the seaweed mud coating of adding clear water and stirring. Mix well.

[0032] Wherein, the spraying mechanism 42c includes a through hole c1, a cover plate c2, a slider c3, and an elastic rod c4. The throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com