Rail feeding method, rail feeding system and computer storage medium

A technology of feeding system and track, applied in conveyor objects, conveyor control devices, metal processing, etc., can solve the problem of inflexible transmission and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

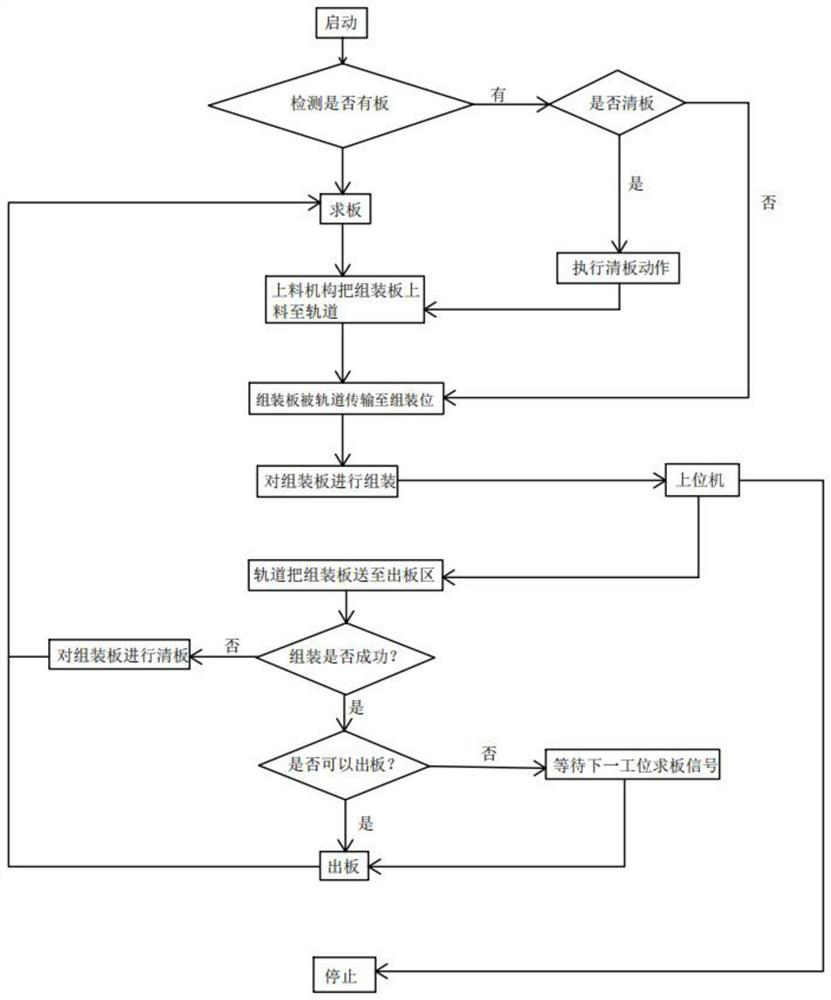

[0050] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a track feeding method, comprising the following steps

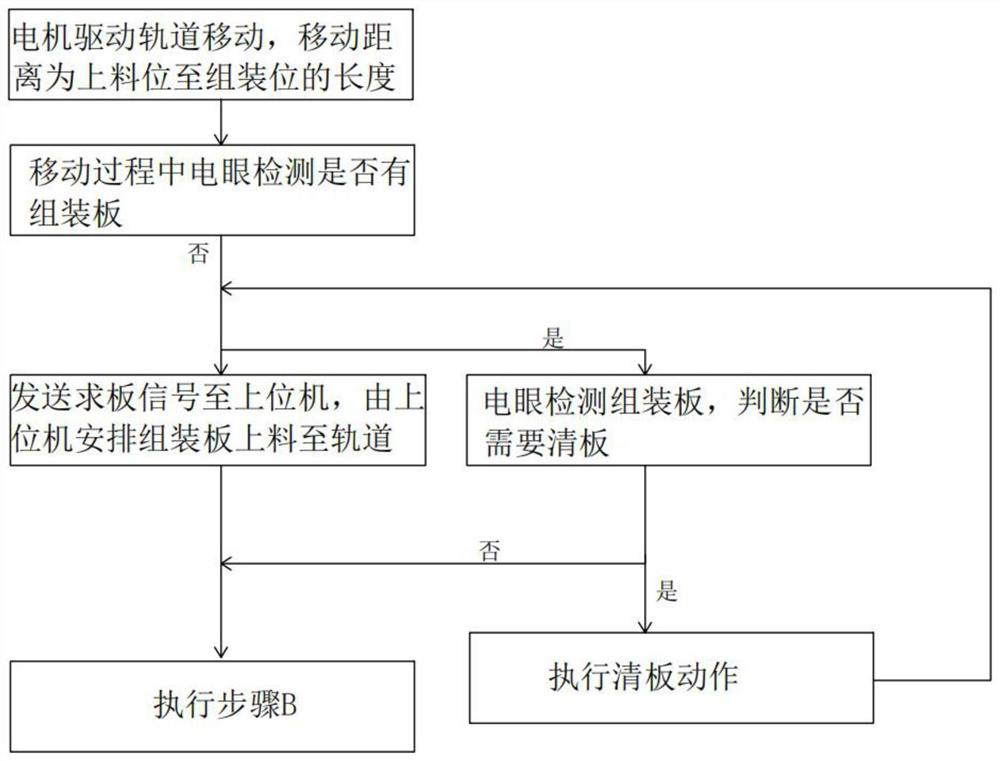

[0051] A. The track self-checks whether there is an assembly board. If there is an assembly board, it will be processed according to the instructions of the host computer. If there is no assembly board, the assembly board will be fed to the track by the feeding mechanism; after the self-inspection is completed, then perform step B ;

[0052] B. The track transports the assembly board to the assembly position, and the detection device detects the assembly board and sends a signal to the host computer;

[0053] C. The upper computer control device assembles the assembly plate on the assembly position;

[0054] D. The assembled board is transported by the track to the board-out area;

[0055] E. Check whether the assembled board is successfully assembled in the board-out area, if it is successful, execute step F, if not, execute step G;

[00...

Embodiment 2

[0084] Such as Figure 5 As shown, this embodiment provides a track feeding system, including

[0085] The track control module is used to drive the start and stop of the track to transport the assembly board;

[0086] The detection module is used to detect whether an assembly board is placed on the track and whether the assembly board has been assembled successfully;

[0087] The board cleaning module is used to drive the board cleaning mechanism to remove the assembled boards that are unsuccessful in assembly or determined to be removed.

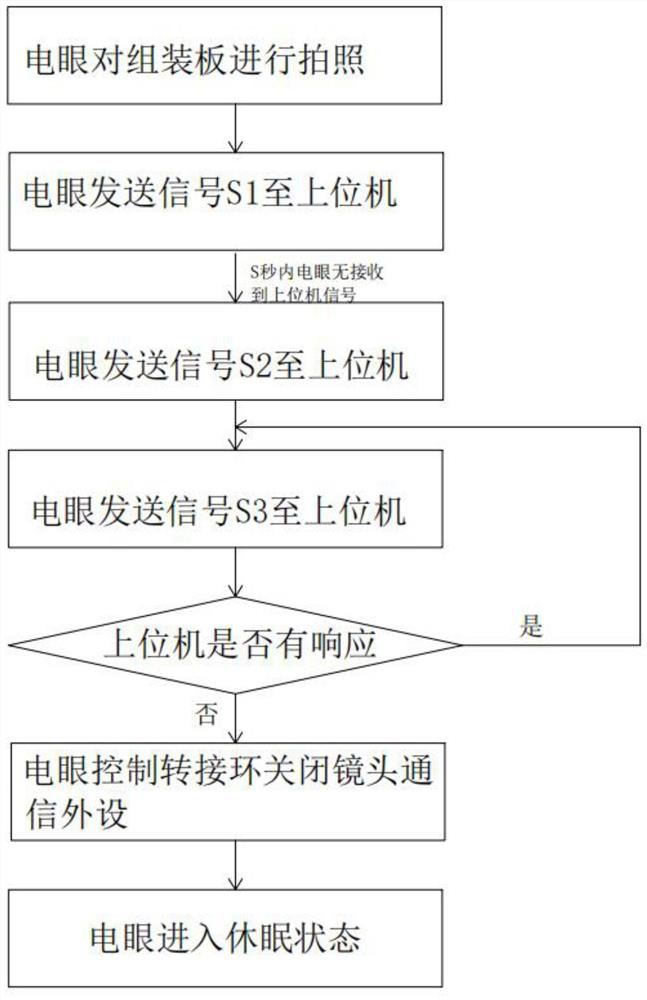

[0088] Specifically, the detection module includes

[0089] The shooting module is used to control the electric eye to take pictures;

[0090] The adjustment module is used to control the aperture and focal length of the electric eye adjustment adapter ring;

[0091] The dormancy module is used to send signals to the host computer according to the actions of the shooting module. When the shooting module does not shoot at intervals of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com