Corner cutting mechanism for refrigerator door sealing strip

A technology for sealing strips and refrigerator doors, applied in metal processing and other directions, can solve problems such as aggravating tool and motor wear, and achieve the effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

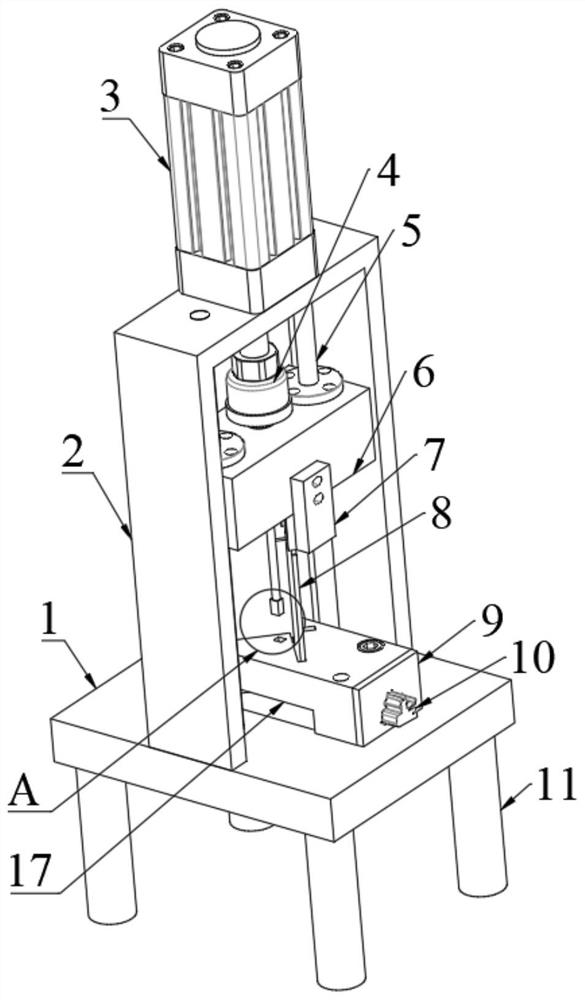

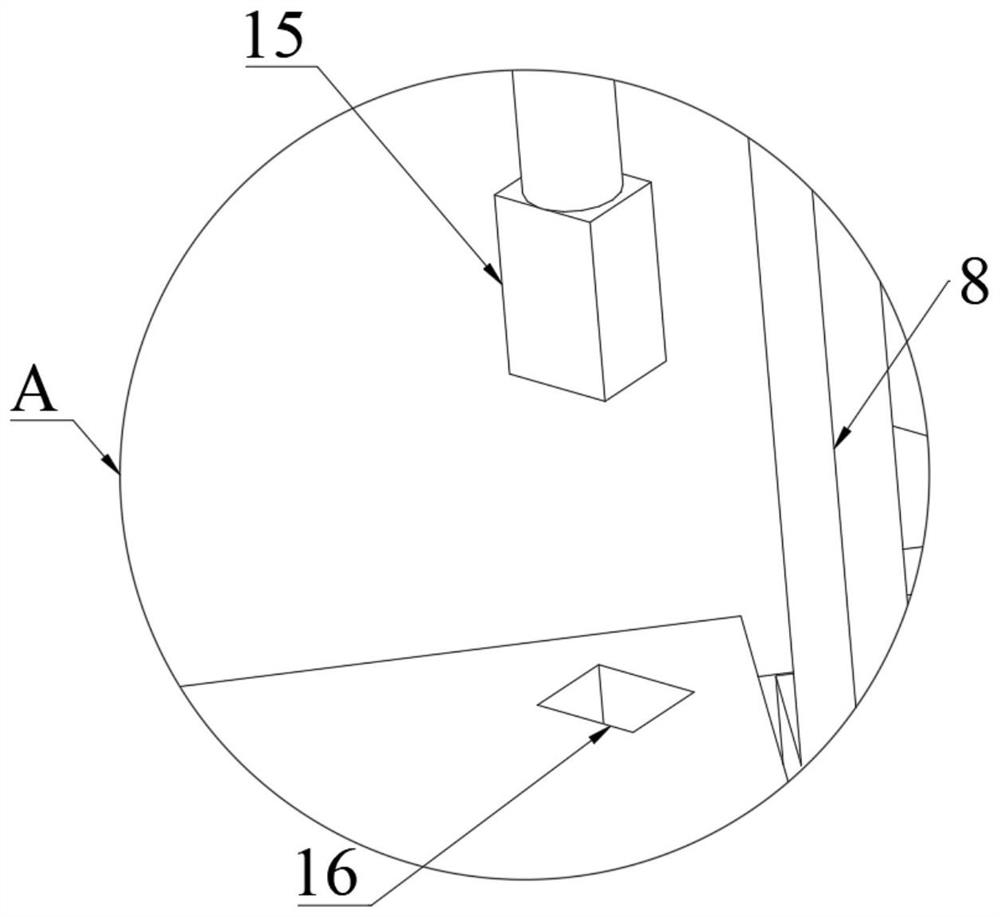

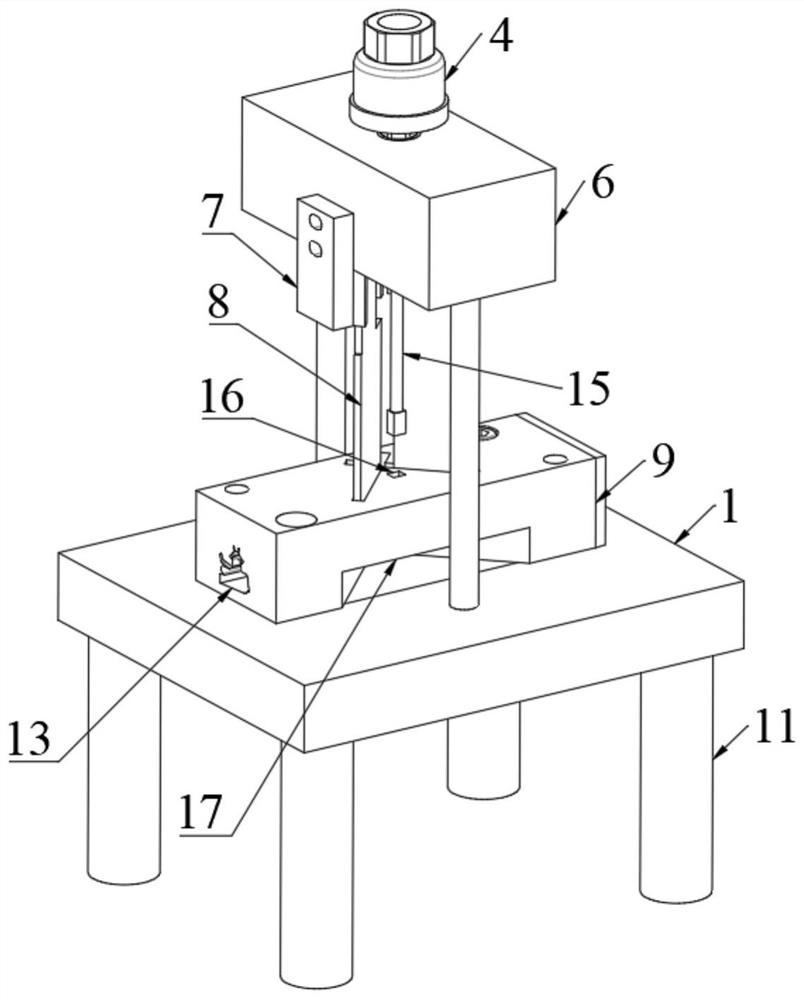

[0047] figure 1 It is a structural schematic diagram of a corner-cutting mechanism of a refrigerator door sealing strip according to an embodiment of the present invention; Figure 4 It is a structural schematic diagram of a cutting die in a corner cutting mechanism of a refrigerator door sealing strip according to an embodiment of the present invention. exist figure 1 and Figure 4 Among them, the chamfering mechanism may include a cutting die 9, at least two blades 8 and a driving assembly. Specifically, the cutting die 9 may include a rubber strip guide groove 13 , at least two blade grooves 12 and a scrap groove 17 .

[0048] The rubber strip guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com