Hoisting machinery suitable for strip-shaped building material and provided with anti-falling mechanism and application method for hoisting machinery

A technology of anti-dropping and hoisting, applied in the field of hoisting and transportation of building materials, can solve the problems of strip-shaped building materials falling, high safety risks, and threats to the life safety of staff, so as to achieve the effect of guaranteeing level and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

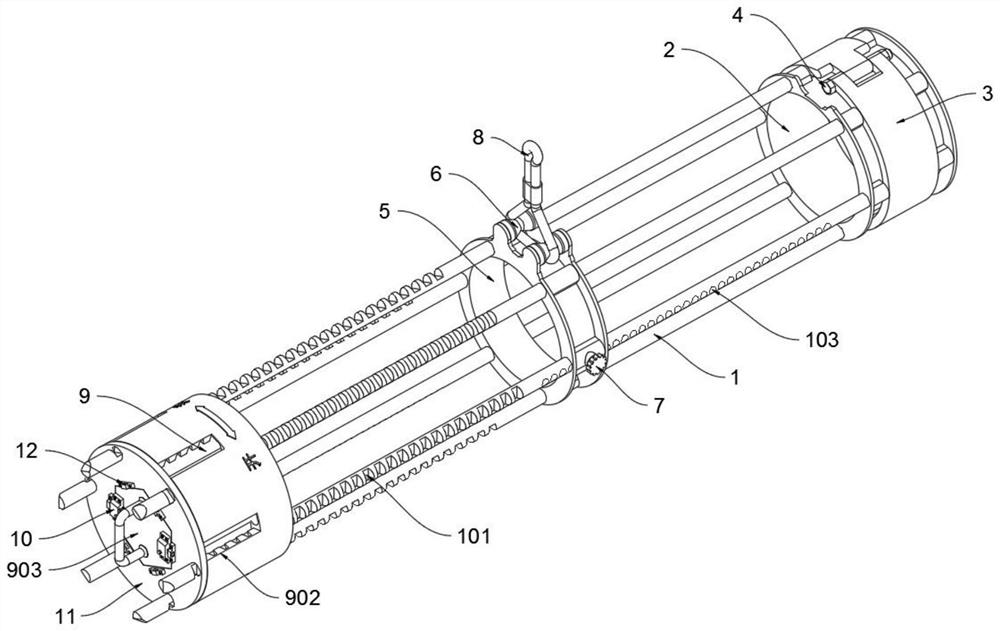

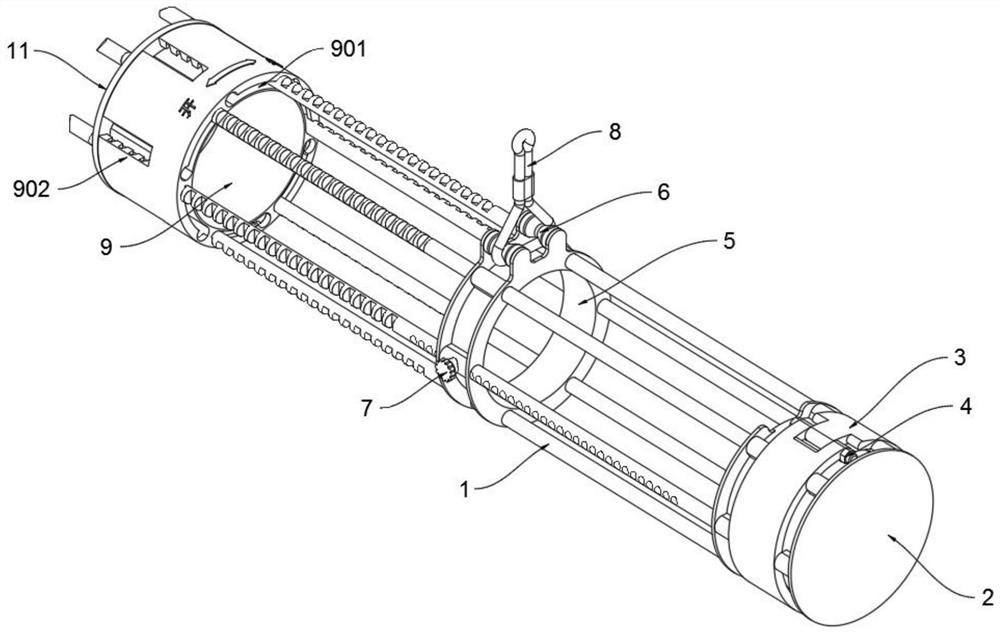

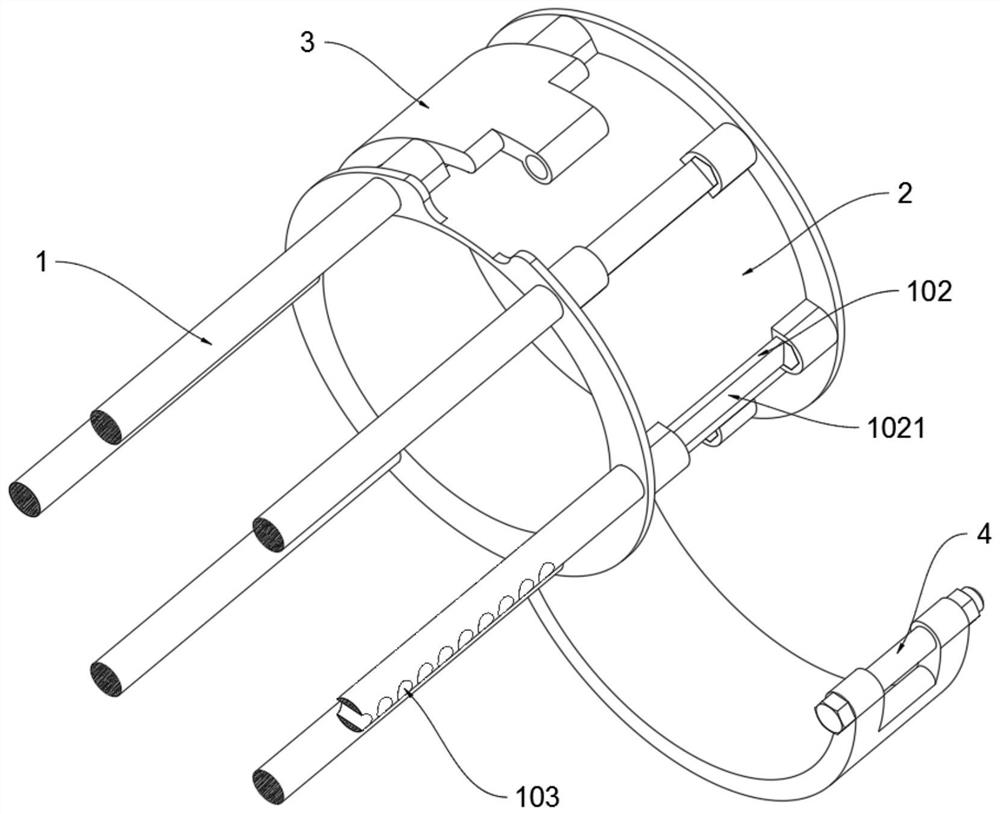

[0036] as attached figure 1 to attach Figure 7 Shown:

[0037] The present invention provides a hoisting machine suitable for strip-shaped building materials equipped with an anti-drop mechanism and a method of use thereof, including a connecting rod 1 and a movable hoisting cylinder 5;

[0038] There are six connecting rods 1 in total, and the right end of the connecting rod 1 is respectively connected with the hoisting right cylinder 2 and the limit hoop 3, and the left end of the connecting rod 1 is respectively connected with the hoisting left cylinder 9 and the locking plate 11;

[0039] The limit hoop 3 is composed of two parts, the bottom ends of the two parts of the limit hoop 3 are rotatably connected to each other, and the top ends of the two parts of the limit hoop 3 are fixedly connected by fastening bolts 4;

[0040] The movable hoisting tube 5 is connected to the outside of the connecting rod 1, and the top of the movable hoisting tube 5 is rotatably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com