Universal-angle lorry-mounted crane telescopic boom

A truck-mounted crane and telescopic boom technology, applied in the direction of cranes, etc., can solve the problem of inability to adjust the rotating boom at multiple angles, and achieve the effect of enhancing the size or components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

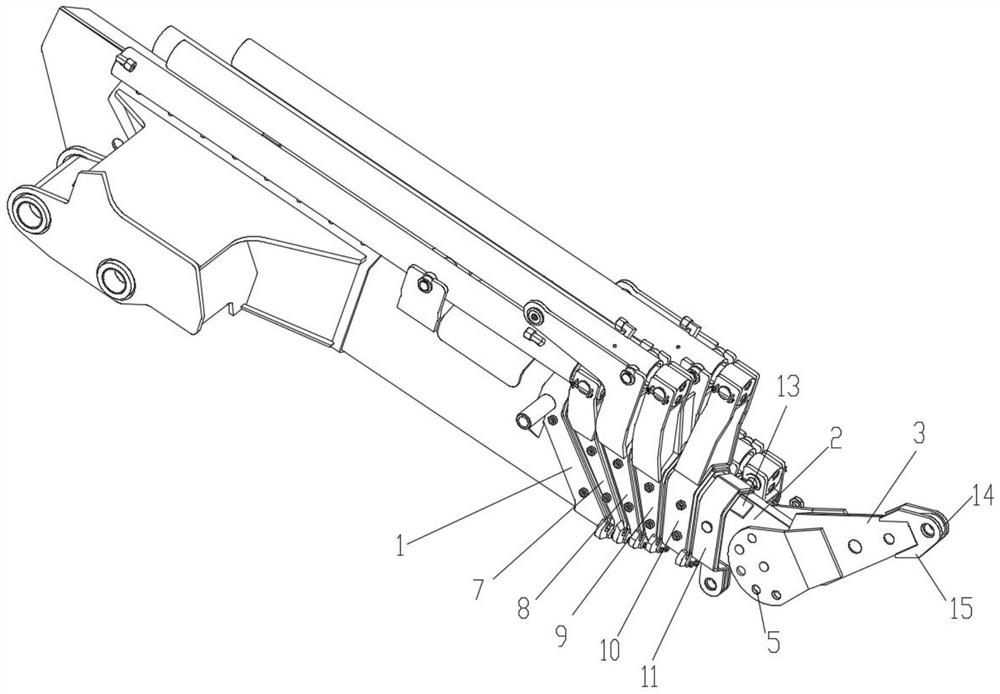

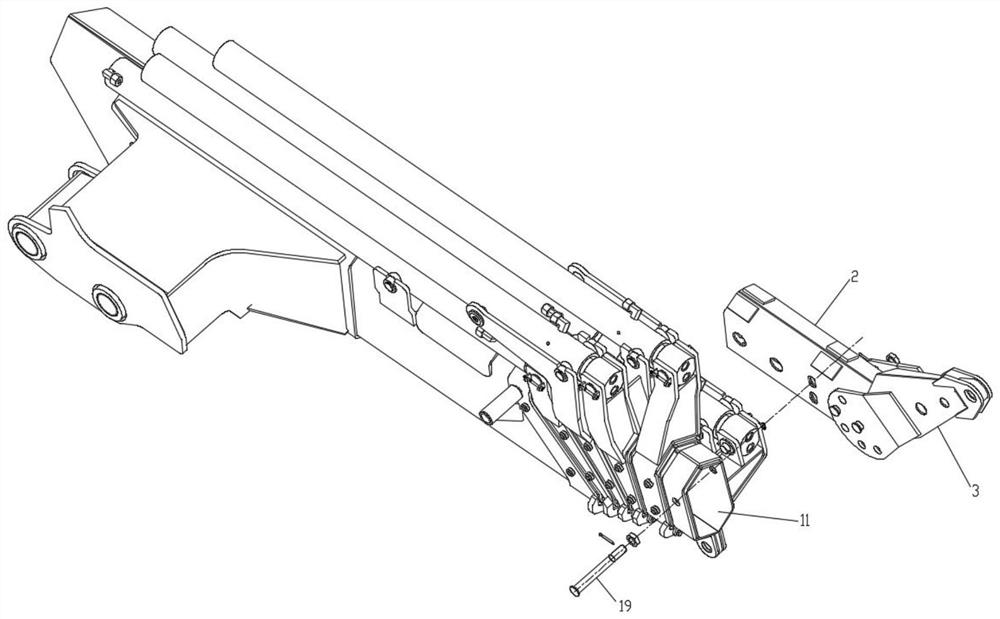

[0030] Such as Figure 1 to Figure 3 As shown, it is an embodiment of the present invention, a telescopic arm of a truck-mounted crane with a universal angle, including a main arm body 1 and a telescopic assembly. The telescopic assembly is installed on the main arm body 1, and the telescopic assembly is suitable for The axis of 1 moves in the direction of stretching. The side of the telescopic assembly facing away from the main arm body 1 is equipped with a hand arm 2. The hand arm 2 is detachably connected to the telescopic assembly. The hand arm 2 is installed on the side facing away from the telescopic assembly. There is a rotating arm 3, a central hole 4 and a circumferential hole 5 are opened on the rotating arm 3, and a positioning hole 6 is opened on the telescopic assembly, and the central hole 4 and the circumferential hole 5 are respectively suitable for installing a positioning piece and passing through the positioning hole 6 to lock Tight, multiple sets of circumf...

Embodiment 2

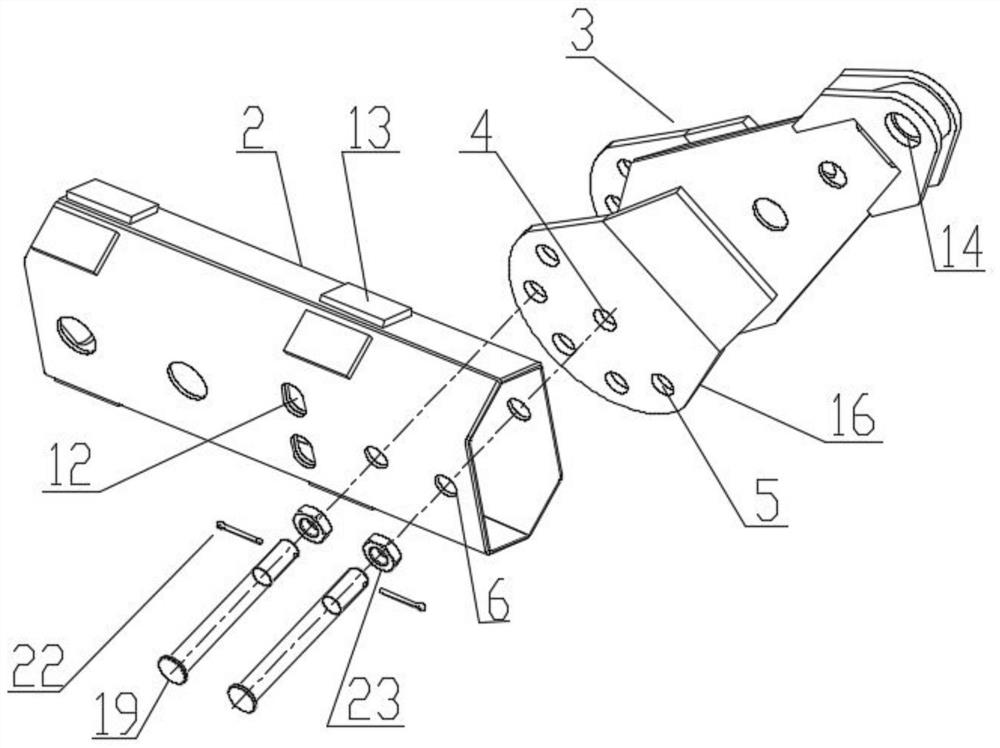

[0037] Such as Figure 4 to Figure 7As shown, it is another embodiment of the present invention. On the basis of Example 1, preferably, the positioning member includes a cylindrical sleeve 17, and the rotating part includes a side plate 16, and the side plate 16 is provided with two sets of circumferential holes. 5 and the central hole 4 are set on two sets of side plates 16, one end of the cylindrical sleeve 17 is rotationally connected with one set of side plates 16, and the other end of the cylindrical sleeve 17 extends to the central hole 4 on the other set of side plates 16. And pass through, the cylindrical sleeve 17 is provided with a gear part, and the rotating part also includes an engagement plate 18, and the gear part is engaged with the engagement plate 18;

[0038] A pin shaft 19 is installed in the cylindrical sleeve 17, and the pin shaft 19 is suitable for being sleeved in the cylindrical sleeve 17. A locking piece is installed at one end of the cylindrical slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com