Structure and method for reinforcing light wood structure shear wall

A wood structure and shear wall technology, applied in building construction, building maintenance, construction, etc., can solve the problems of low stiffness and bearing capacity, and achieve the effects of improving seismic performance, convenient construction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

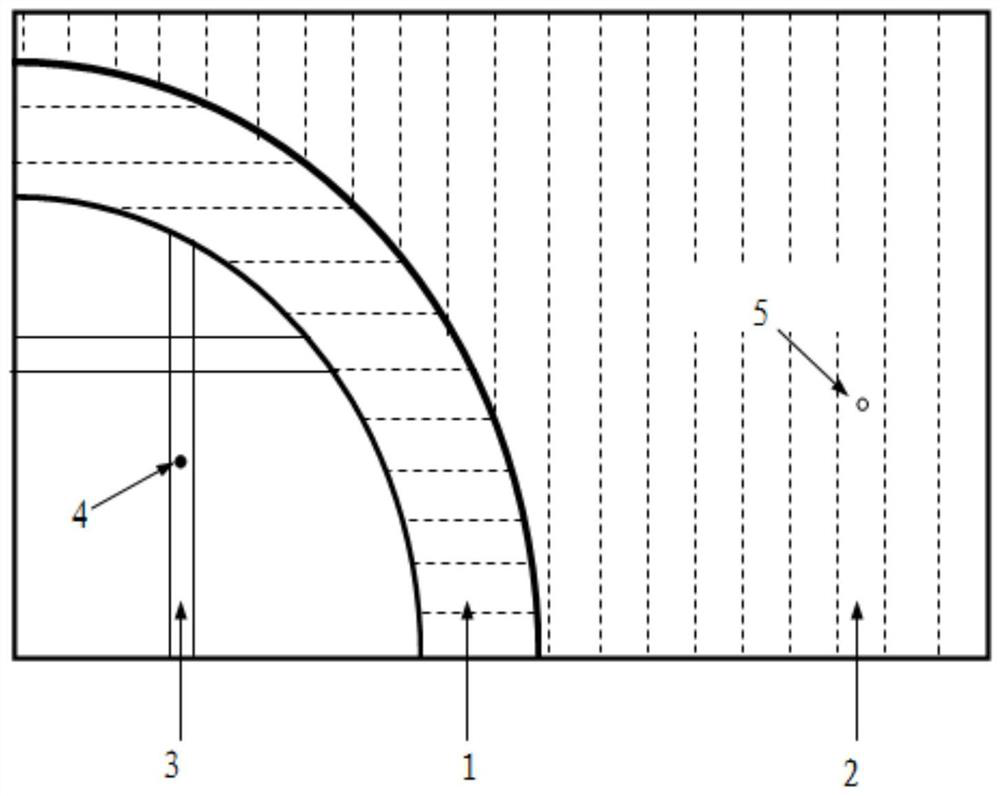

[0021] see figure 1 , figure 1 Shown is a front cutaway view of a reinforced lightweight timber shear wall. Stud 3, existing OSB panel 1, and newly added OSB panel 2 in the figure are not on the same level, so they all show partial views. For example, the existing OSB panel in the figure is represented as a fan ring, but it is not actually a fan ring, but should be the same size as the entire shear wall.

[0022] For details, please refer to figure 1 , a structure for strengthening a light wood structure shear wall, comprising stud columns 3, an existing OSB panel 1, the two are fixed by structural nails 4, and the outer layer of the existing OSB panel 1 is attached with a new An OSB panel 2 is added, and self-tapping screws 5 pass through the newly added OSB panel 2 and the existing OSB panel 1 in turn, and their ends extend into the stud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com